Numerical control machining device for steel pipe bundle flange hole

A technology for processing equipment and steel pipe bundles, applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve the problems of low production efficiency, high labor intensity, high cost, etc., to reduce processing energy consumption and improve processing Efficiency, the effect of ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

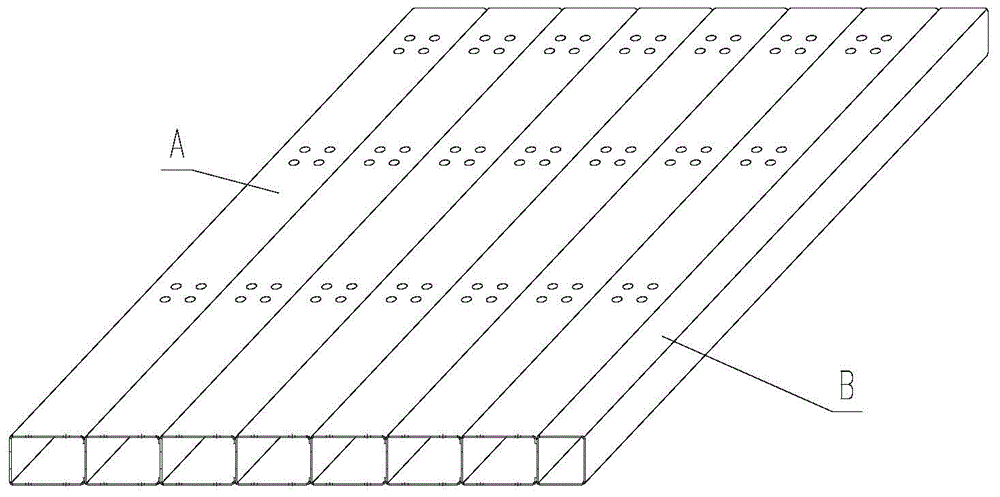

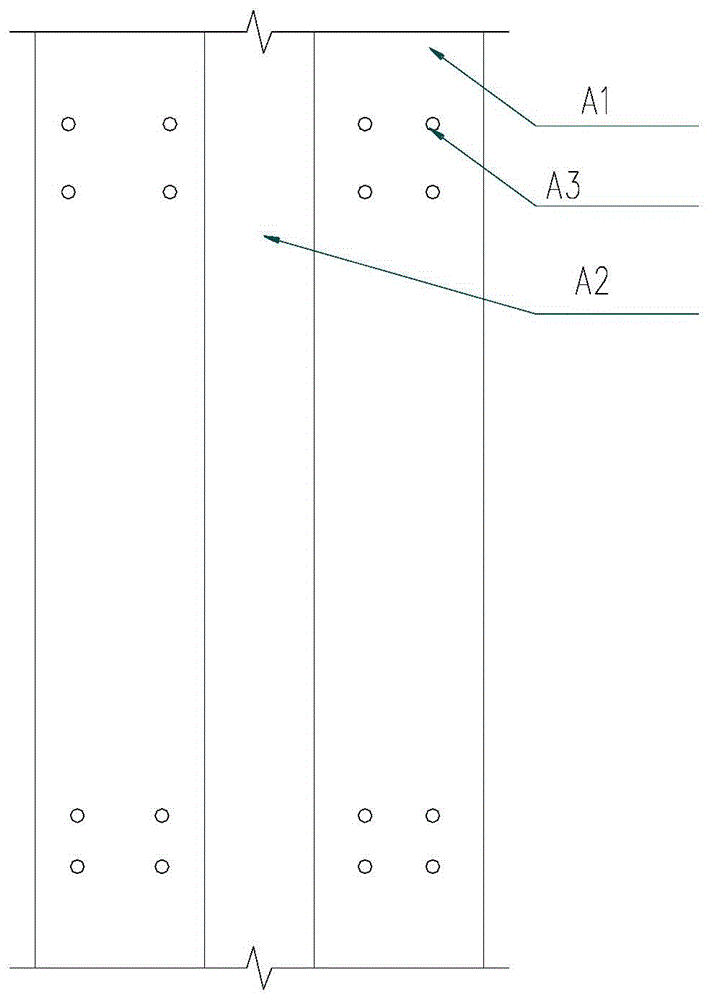

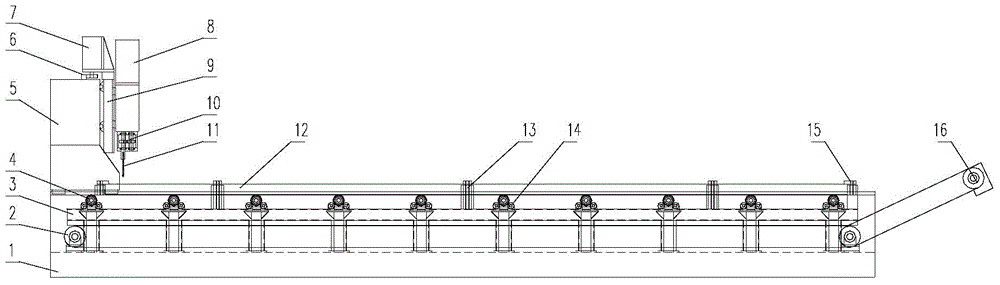

[0045] refer to Figure 1a to Figure 6b , CNC processing equipment for steel tube beam flange holes, including a supporting base 1, along the length direction of the base 1, a number of conveying rollers 4 are arranged in parallel, and several of the conveying rollers 4 are used to form a steel pipe A workbench for beam member 12 processing;

[0046] The base 1 is provided with a gantry frame 5 that can move along the length direction of the base and is used to install several drilling power heads. The drilling power head 8 can move horizontally along the gantry frame 5 Move; the bottom of the drilling power head 8 is equipped with a drill bit 11 for machining the holes of steel pipe bundle components.

[0047] A horizontal slide 9 is installed on the gantry frame 5, and the horizontal slide 9 is installed on the gantry frame 5 through a rolling linear guide pair, and a lateral movement motor is installed on the top of the horizontal slide 9 7. The horizontal sliding plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com