Device and method for adjusting laser spot size and target positioning

A laser spot and target material technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large instrument influence, low work efficiency, and limited adjustment range, etc. Convenience and clear measurement principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention utilizes the photo paper and the film covered on the photo paper to realize the function of adjusting the light spot and the positioning of the target, and the operation is simple and the cost is low.

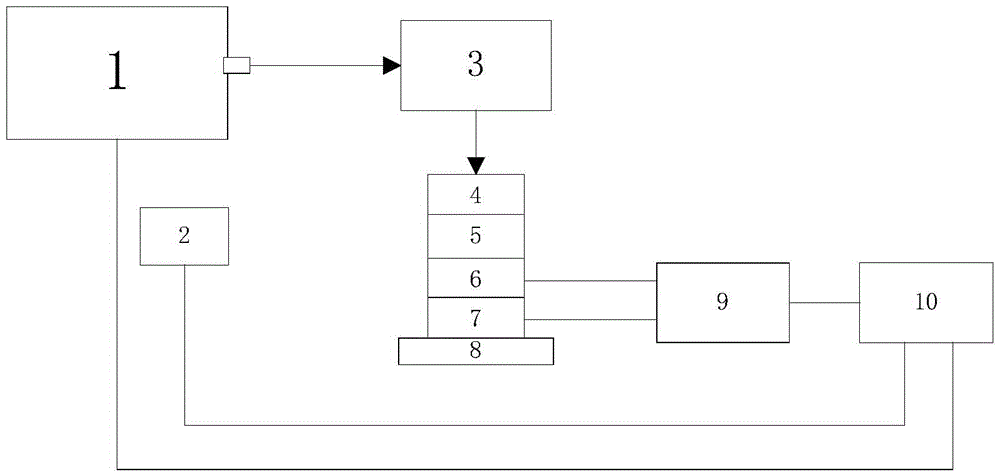

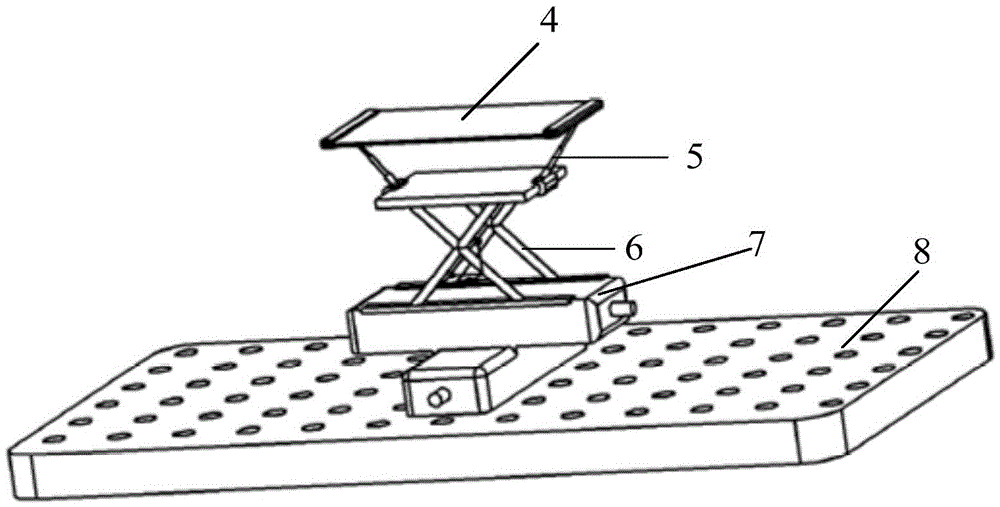

[0028] Such as figure 1 , figure 2 As shown, the device for adjusting laser spot size and target positioning includes laser 1, photoelectric sensor 2, optical path system 3, photographic paper 4, fixture 5, lifting table 6, X-Y motion table 7, multi-threaded hole base 8, servo The motor 9 and the industrial computer 10, the laser 1 is a pulsed laser, the laser parameters can be set by the industrial computer, and connected to the industrial computer 10, the clamp 5 for clamping the photo paper 4 is placed on the lifting platform 6, and the lifting platform 6 is installed on the X-Y On the motion table 7, the X-Y motion table 7 is located on the base 8 of the multi-thread hole table, the servo motor 9 is driven and connected to the X-Y motion table 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com