(2T1R)&(2R) Completely isotropic parallel serial robot mechanism

A technology of robots and revolving pairs, applied in the field of robots, can solve the problems of decoupling and kinematic isotropy, and achieve good motion transmission performance, good stability, and load reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

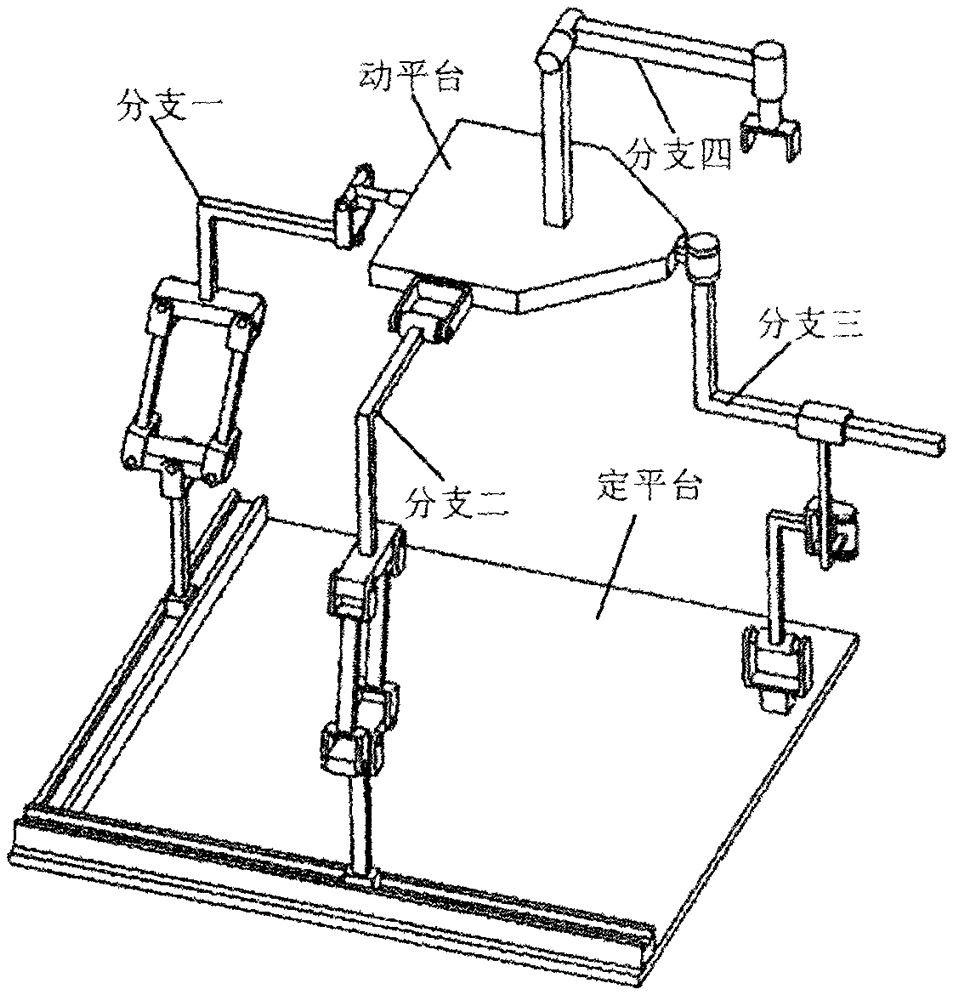

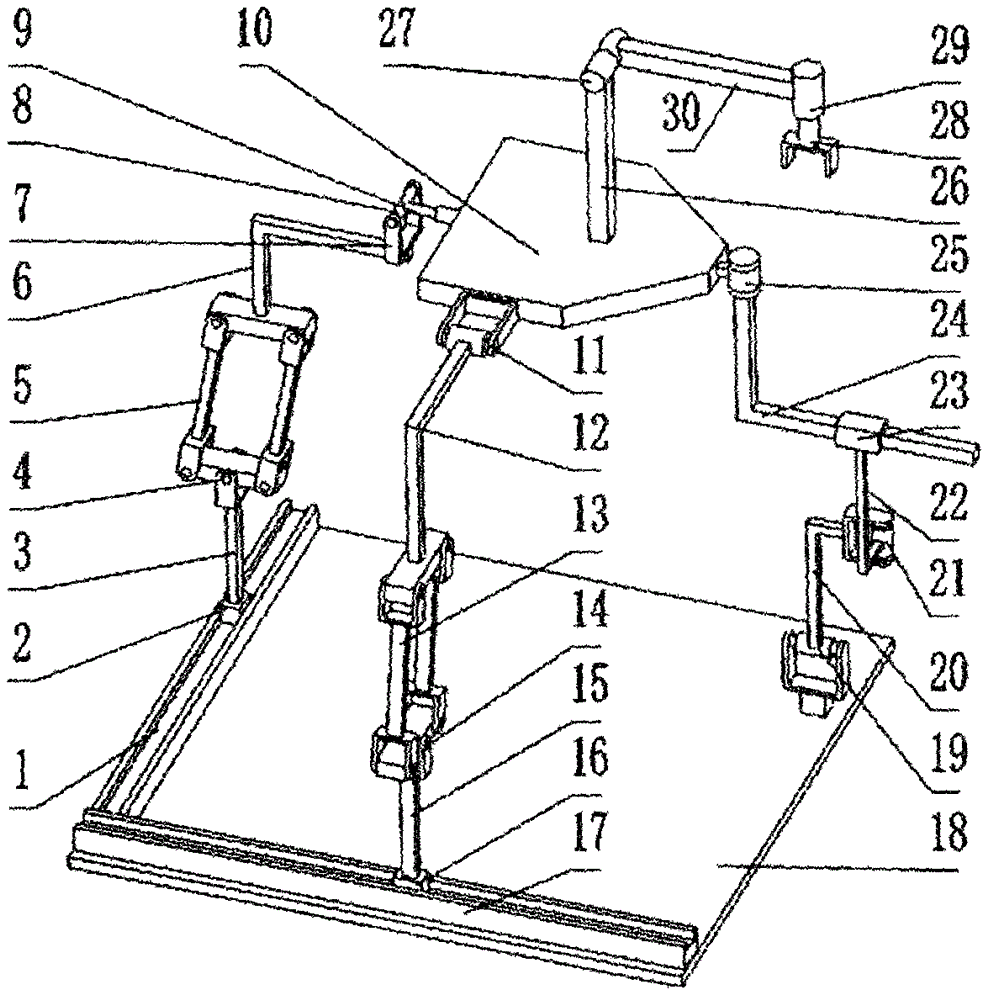

[0014] A (2T1R)&2R fully isotropic hybrid robot mechanism, such as figure 1 , 2 The fixed platform 18 shown is a rectangular structure, and the moving platform 10 is a triangular structure. The adjacent two sides of the fixed platform are provided with right-angle guide rails 1 and 17, and the center line of the right-angle slide rail is parallel to the bottom surface.

[0015] One end of the first connecting rod 3 in branch one is connected with the guide rail 1 through the moving pair 2, the other end of the connecting rod is connected with one end of the parallelogram hinge 5 through the rotating pair 4, and the other end of the parallelogram hinge is connected through a universal hinge 7 is connected with moving platform 10. The moving direction of the moving pair 2 is parallel to the bottom surface. The swivel pair 4 is parallel to the swivel axis 8 of the universal hinge and is perpendicular to the swivel axis 9 at the same time. The rotary pair axis in the parallelog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com