Sleeping-berth structure capable of realizing seat-berth conversion and sleeping berth carriage with same

A sitting-sleeping conversion and sleeper technology, which is applied in the field of sleeper cars, can solve the problems of affecting the comfort of passengers, inconvenient turning, and can only lean on the partition wall, etc., to improve the transport capacity of the car, the overall structure is simple and practical, and the legs are enlarged. The effect of the internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

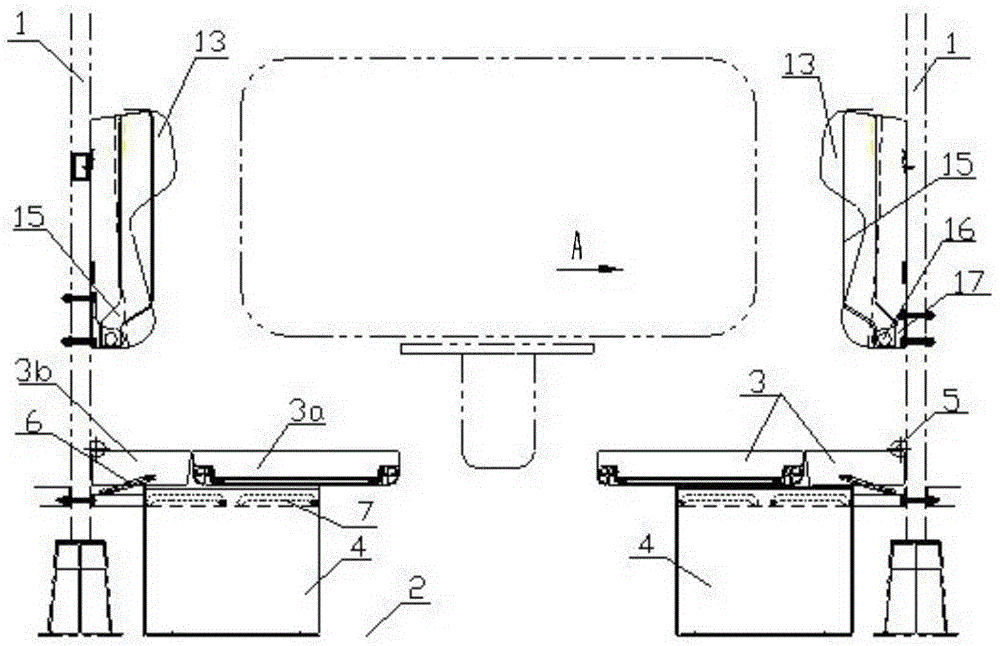

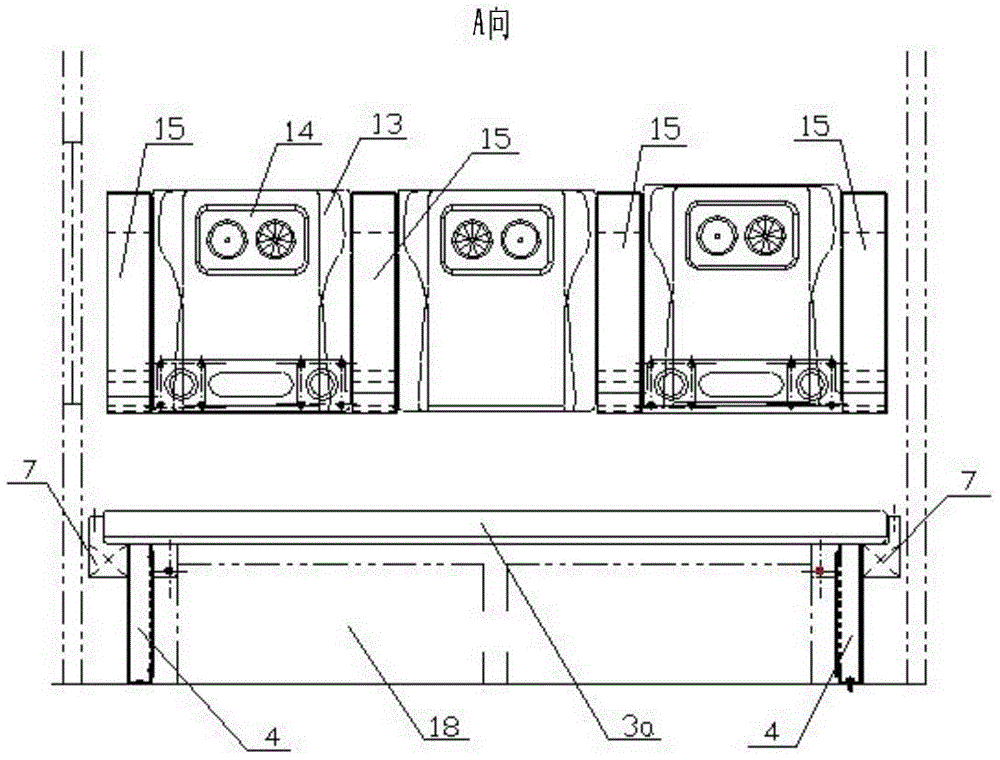

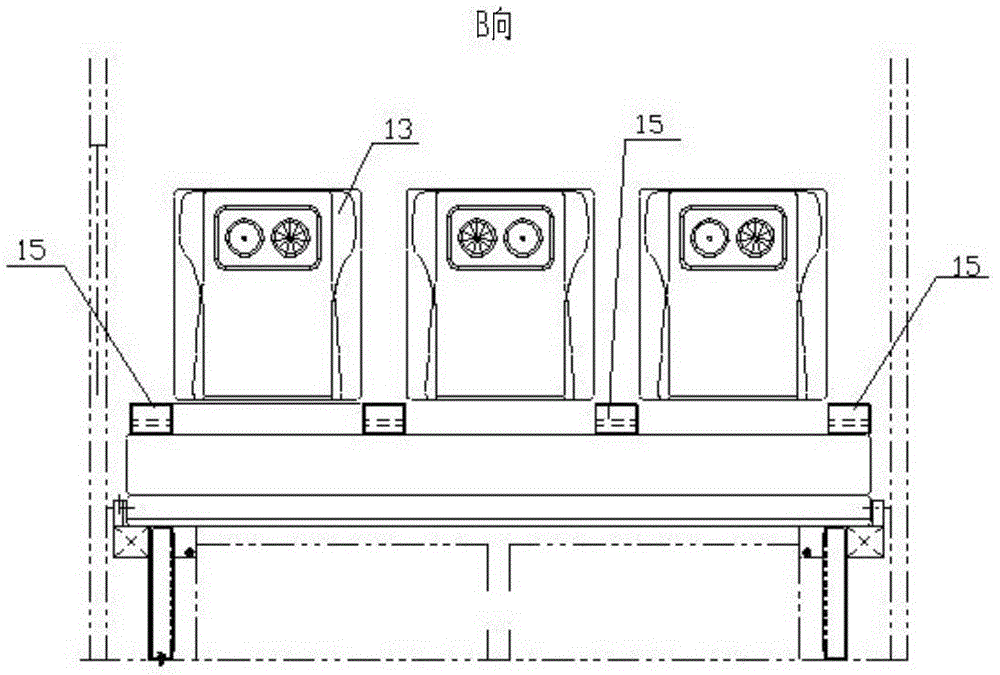

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] The present invention provides a sleeper carriage, in which a plurality of partition walls 1 are arranged to divide the carriage into multiple spaces, and two or three layers of sleepers are arranged on the partition walls 1 on both sides of each space, wherein the sleepers on the lower floor are fixed On the carriage floor, one or two layers of upper berths are arranged above the lower berths, and the upper berths are fixed on the partition wall. During the daytime, there is no need to use the upper berths and when the number of passengers on railway vehicles soars on special days such as Spring Festival travel, Flip up the upper sleeper on one or two floors, and convert the lower sleeper into a seat at the same time, making full use of the compartment space to improve the transport capacity of the compartment.

[0035] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com