Car roof cover and machining method for car roof cover

A roof cover and reinforcement technology, applied in chemical instruments and methods, vehicle parts, superstructure sub-assembly, etc., can solve the problems of inconvenient manufacture and assembly of the roof cover, heavy weight, etc., and achieve the convenience of automobile manufacturing and assembly , reduce the weight of the vehicle body, reduce the effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

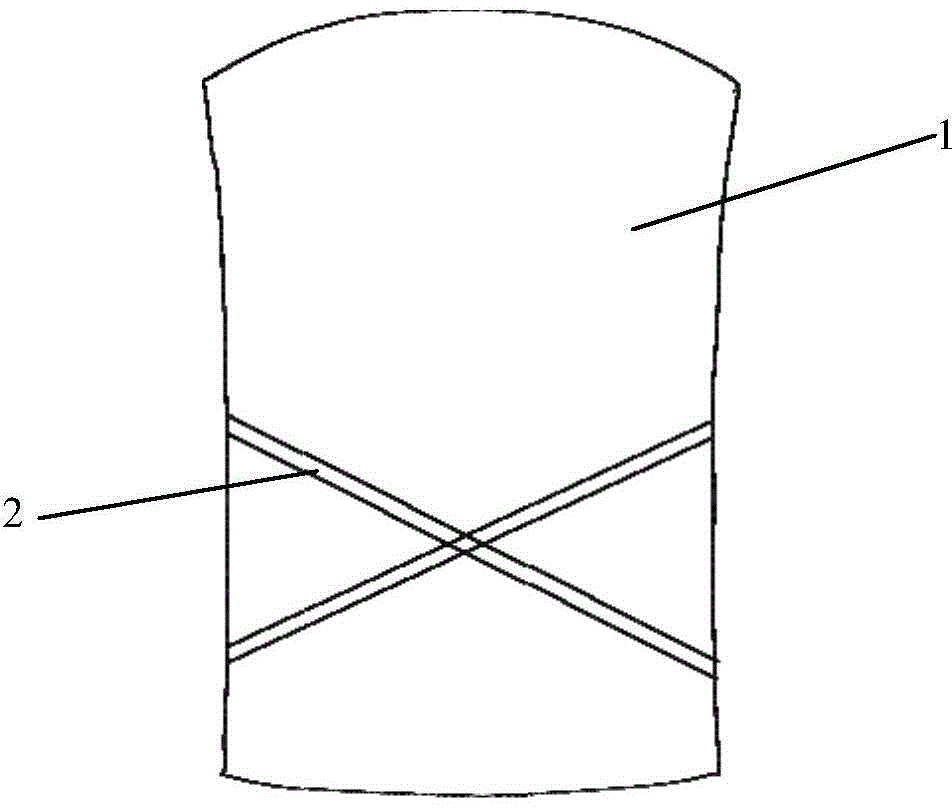

[0033] According to one aspect of the present invention, there is provided a roof cover, such as Figure 1~3 Shown, this roof cover includes:

[0034] A roof cover body 1 and a reinforcement 2, the reinforcement 2 is press-fitted inside the roof cover body 1;

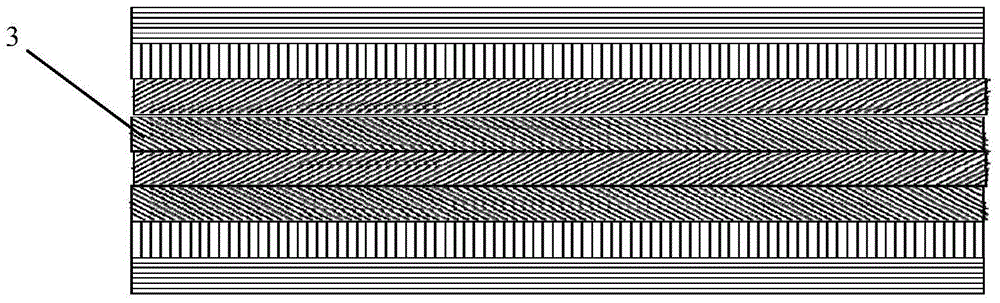

[0035] Wherein, the roof cover body 1 includes a plurality of single-layer continuous carbon fiber prepregs 3 of the first structure, and the single-layer continuous carbon fiber prepregs 3 of the first structure are stacked in sequence, and adjacent to the first The radial weaving directions of the single-layer continuous carbon fiber prepreg 3 of the structure are different;

[0036] The reinforcing member 2 includes a plurality of single-layer continuous carbon fiber prepregs 3 of the second structure, and the plurality of single-layer continuous carbon fiber prepregs 3 of the second structure are stacked in sequence, and the adjacent single-layer carbon fiber prepregs of the second structure The radial knitting di...

Embodiment 2

[0047] According to another aspect of the embodiments of the present invention, a method for processing a roof cover is also provided, such as Figure 4 As shown, the method includes:

[0048] Step S41 , immersing the carbon fiber cloth in a prepreg solution with a predetermined viscosity to form a single-layer continuous carbon fiber prepreg 3 with a third structure.

[0049] Among them, the continuous carbon fiber tow can be made into radial-woven carbon fiber cloth, or the carbon fiber woven cloth sold in the market can be directly purchased. Thereafter, the carbon fiber cloth is dipped into the prepreg solution to form a single-layer continuous carbon fiber prepreg cloth 3 having a third structure in the original shape.

[0050] Optionally, the prepreg solution is an unsaturated polyester resin solution. Therefore, the thickness of the single-layer carbon fiber prepreg cloth of the third structure can be controlled at 0.2 mm by adjusting the viscosity of the unsaturated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com