A converter heat treatment parts cooling device

A converter heat treatment and cooling device technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problem of uneven hardness of workpieces, achieve the effects of improving quenching quality, reducing hardness dispersion, and preventing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

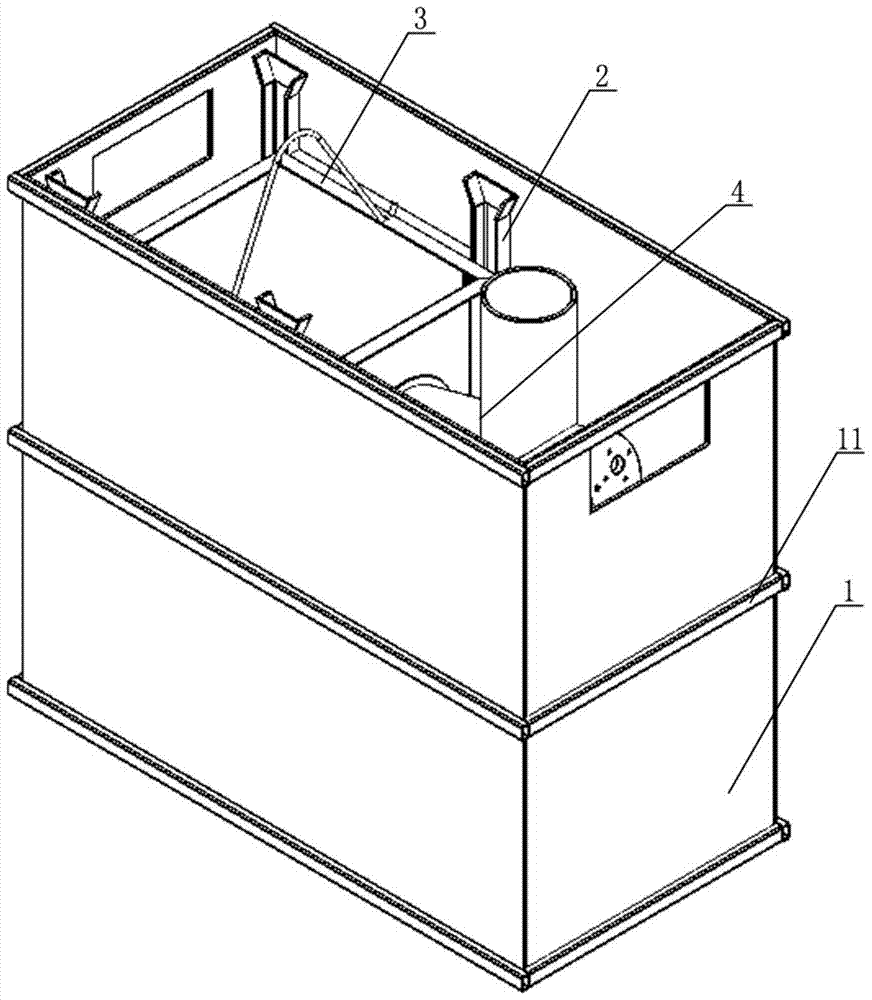

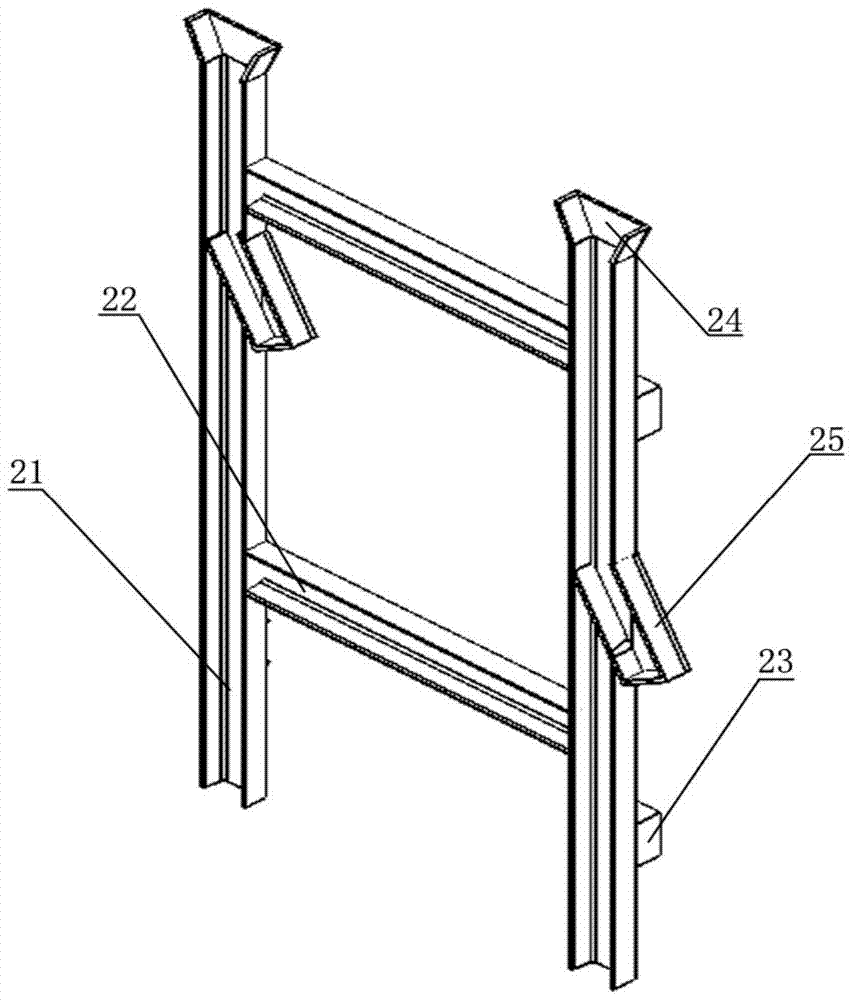

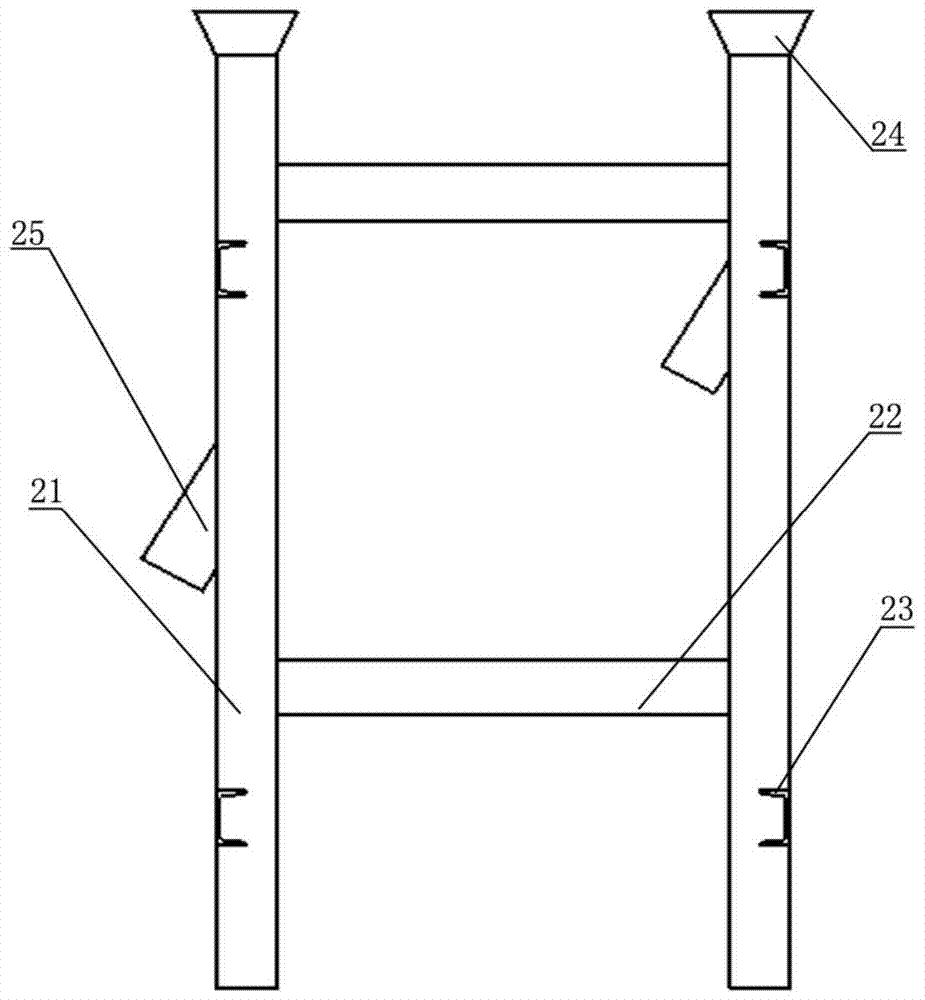

[0018] Such as figure 1 and Figure 5 The shown cooling device for heat treatment parts of a converter includes a converter, a cooling oil tank, a smoke exhaust pipe and a circulating oil circuit. At the same position on the two opposite inner walls of the fuel tank 1, the four side walls and the bottom of the basket 3 are all mesh plate structures, and one side wall of the basket 3 is provided with a through hole 31, and the basket 3 rests on the On the support 2, the guide pipe 4 includes a feed pipe 41 and an oil pipe 42 fixed to each other, one end of the oil pipe 42 is provided with a positioning sleeve 43, and the other end of the oil pipe 42 is provided with an end cover 44, and the oil pipe is provided with The angle between one end of the positioning sleeve 43 and the feed pipe 41 is 100°-110°, and the end of the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com