Drilling platform pile leg segmented closing technology

A drilling platform pile leg and pile leg technology, which is applied to artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of long-distance sea transportation such as high cost of pile legs, heavy closing workload, and serious influence of sea conditions, etc., to achieve The effect of improving closing efficiency, shortening closing period, and simple closing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

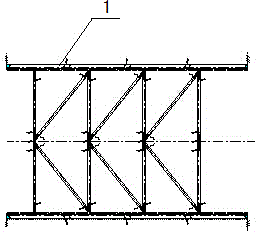

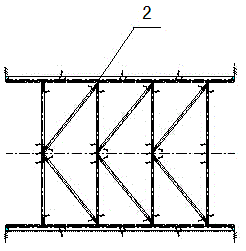

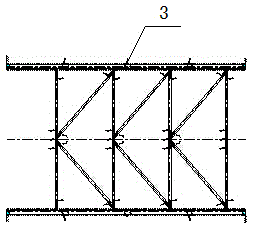

[0043] The invention discloses a segmental closing process of pile legs of a drilling platform. The method mainly includes hoisting and closing the offshore pile legs after the positioning of the platform piles is completed; Figure 1 to Figure 5 As shown, the hoisting legs are divided into five sections from bottom to top before closing, including the first leg segment 1, the second leg segment 2, the third leg segment 3, the fourth leg segment A4 and The fourth leg segment B5; the hoisting method is to use the floating crane to close the first leg segment 1, the second leg segment 2 and the third leg segment 3, and use the crawler crane to close the fourth leg segment A4 and the fourth leg segment B5; the specific steps for hoisting and closing the offshore legs are as follows:

[0044] The first step, the legs are in place: before closing the first leg segment 1, the second leg segment 2, the third leg segment 3, the fourth leg segment A4 and the fourth leg The leg section...

Embodiment 2

[0057] In this embodiment, on the basis of Example 1, in step (1), after the pile legs are in place, pre-close measurement is performed on each pile leg section on the wharf platform, mainly measuring the distance between the closing teeth and the center of the chord. Width, draw a closing reference line at the position of the closing mouth of the rack and punch it to ensure that the tooth spacing meets the tolerance requirements when closing and positioning.

Embodiment 3

[0059] In this embodiment, on the basis of Embodiment 1, in step (2), before the auxiliary positioning tooling is welded, draw a closing reference positioning installation line on the tooling plate, and the reference line is consistent with the rack reference line on the rack plate Consistent, taking into account the closing mouth welding shrinkage, such as Figure 13 As shown, after the closing mouth is positioned, the H dimension of the tooth spacing before welding should be controlled within 314.16mm+3mm as much as possible, and the H dimension of the tooth spacing after welding should be controlled within 314.16mm±2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com