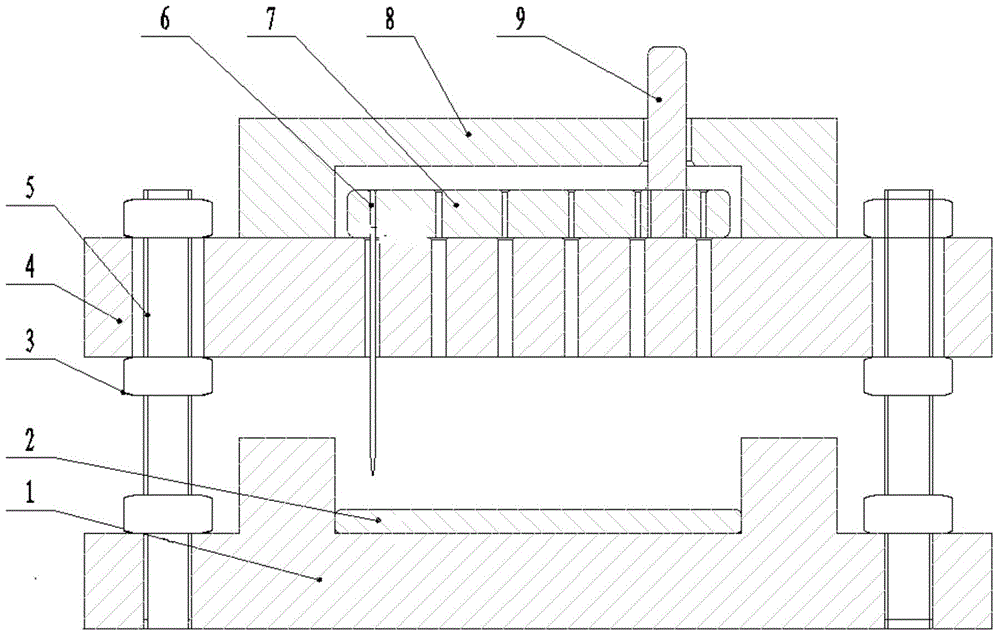

Needle-plate electrode corona discharge assembly for AC-DC high voltage test

A high-voltage test and corona discharge technology, applied in the direction of testing dielectric strength, etc., can solve the problems of large difference between electrodes and cannot be shared, and achieve the effect of simple wiring, convenient assembly and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Connect the high-voltage electrode column 9 of the corona device to the high-voltage AC power supply, place the silicone rubber with a size of 80mm×40mm on the lower insulating support plate 1, and adjust the distance from the needle electrode 6 to the sample by the insulating nut 3 to be 50mm; And ground the lower metal plate 2.

[0036] (2) Adjust the output voltage to 10kV by adjusting the high-voltage AC power supply, and the pressurization time is 6h;

[0037] (3) After the pressurization is completed, the sample is taken out, and the static contact angle at different positions on the surface is measured.

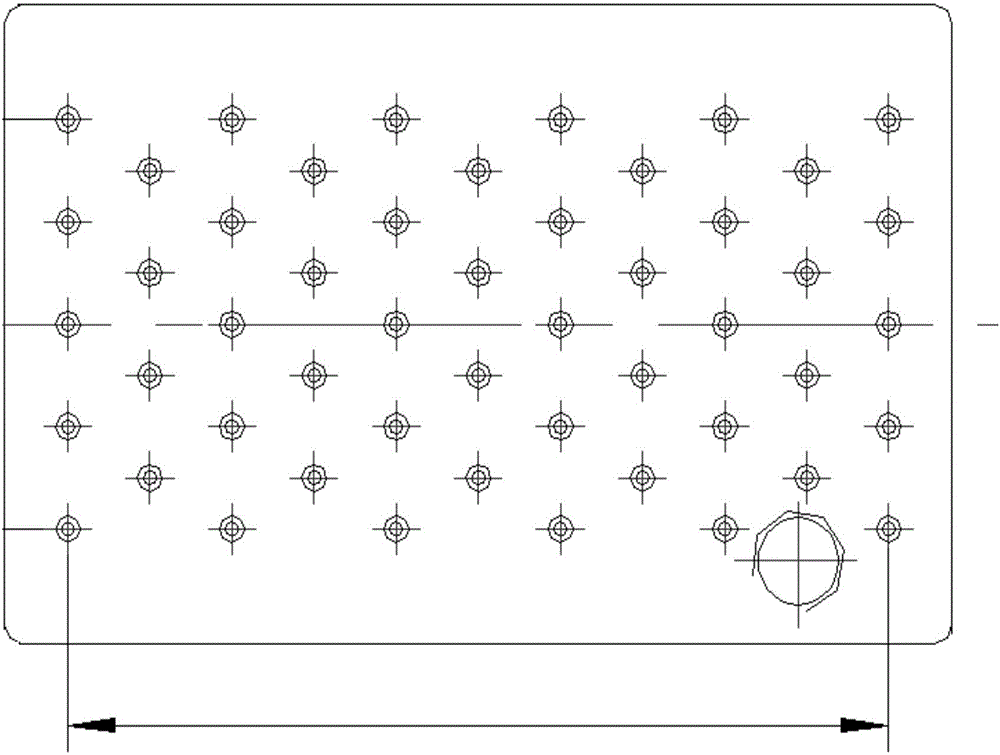

[0038] (4) Comparing the static contact angle at different positions on the sample surface, it is found that the static contact angle distribution on the sample surface is uniform, indicating that the aging degree of the sample surface is evenly distributed.

Embodiment 2

[0040] (1) Connect the high-voltage electrode column 9 of the corona device to the high-voltage DC power supply, place the epoxy resin sample with a size of 80mm×40mm on the lower insulating support plate 1, and adjust the distance between the needle electrode 6 and the sample through the insulating nut 3 is 30mm; and the lower metal plate 2 is grounded.

[0041] (2) Adjust the output voltage to +3kV by adjusting the high-voltage DC power supply, and the pressurization time is 15 minutes;

[0042] (3) After the pressurization is completed, the sample is taken out, and the potential at different positions on the surface is measured with an electrostatic potentiometer.

[0043] (4) Comparing the surface potential distribution of the sample, it is found that the surface potential distribution of the sample is uniform, indicating that the needle array is evenly arranged, and the charge injected into the sample surface is evenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tip diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com