Human body head three dimensional scanner and three-dimensional modeling method

A head three-dimensional, scanner technology, applied in the field of human body scanning, can solve the problem of lack of three-dimensional equipment and modeling methods, and achieve the effect of high consistency, high speed and small error, and high photo quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

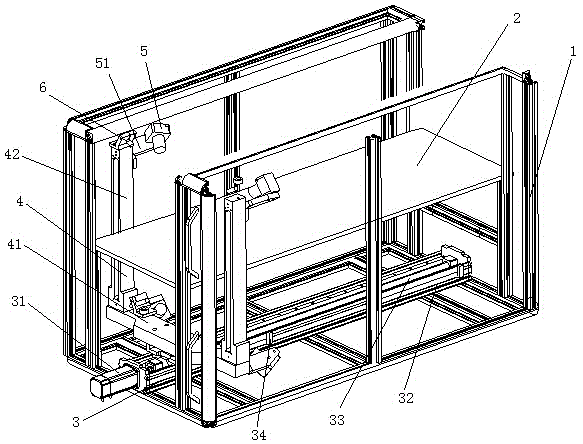

[0049] figure 1 It is a structural schematic diagram of the human body head three-dimensional scanner of the present invention, as figure 1As shown, the present invention provides a three-dimensional scanner for a human head and a three-dimensional modeling method, including: a frame 1, a glass plate 2, a driving device 3, a bracket 4, a camera 5 and a laser 6, and a glass plate 2, a driving device 3, The brackets 4 are all installed on the frame 1; the glass plate 2 is located above the driving device 3; the driving device 3 includes a servo drive motor 31, a slide rail 32, a screw rod 33 and a limit switch 34, and the slide rail 32 is installed on the frame 1. At the bottom, the limit switch 34 and the servo drive motor 31 are all installed on the slide rail 32, and the servo drive motor 31 is connected with the screw mandrel 33; the support 4 includes a crossbeam 41 and two columns 42, and the bottom of the crossbeam 41 is sleeved on the wire by a bearing. On the rod 33, t...

Embodiment 2

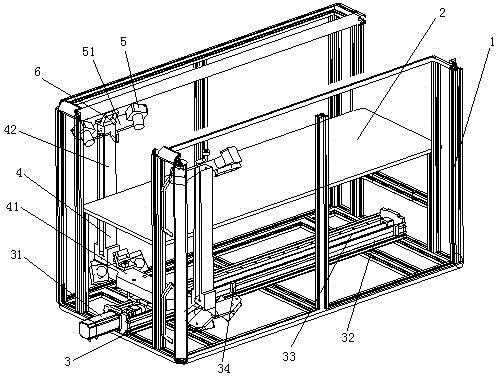

[0053] figure 2 It is the structure schematic diagram of embodiment 2 of human body head three-dimensional scanner embodiment 2, on the basis of embodiment 1, the quantity of word line laser 6 is 4 in the present embodiment, the quantity of CCD industrial camera 5 is 8, 2 One word-line laser 6 is located at the top of two columns 42 respectively, and the remaining two line lasers 6 and the two line lasers 6 at the top of the two columns 42 are symmetrical to the central axis and respectively located on the beam 41. The four CCD industrial The cameras 5 are respectively positioned at the tops of two columns 42 through the rotation shafts 51, and the remaining four CCD industrial cameras 5 are symmetrical to the central axis of the CCD industrial cameras 5 at the tops of the two columns 42, and are respectively positioned on the beam 41 through the rotation shafts 51; the CCD industrial cameras The quantity of 5 is 8, and the frame is square, hexagonal, rectangular or circular....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com