Wind-up light-directing slat, method of production, application, and sun protection system

A technology of protection system and light guide plate, applied in the field of sun protection system, can solve the problems of inability to manufacture, reduction of slats and light entering the line of sight, storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

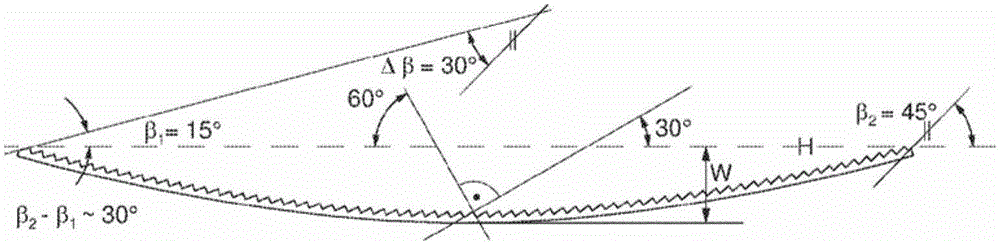

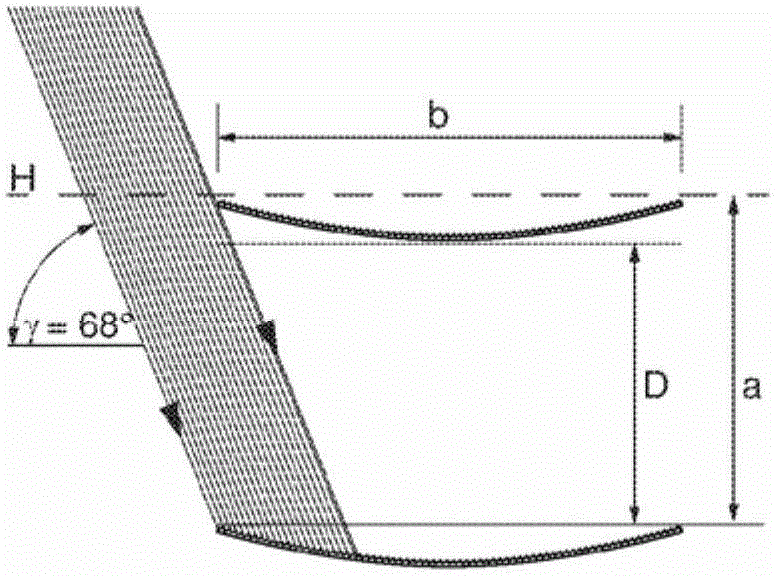

[0065] exist Figure 4 A construction description for the horizontal operating position of the curve is defined in . In the present case, the ratio a / b of the slat distance a to the slat width b is approximately 0.7. However, this ratio can be chosen arbitrarily. For the optional ratio a / b, the solar radiation folding side K in the region of the slat edge will be explained below s Angle of inclination β with respect to the horizontal.

[0066] Valid for horizontal position is α' s =90°-α s . alpha s is the angle of inclination of the shadow line S relative to the vertical line V or relative to the vertical glazing of the building facade to which the sun protection system in which the slats are arranged is applied. For the sun side K in the area of the slat edge relative to the interior space I s Angle of inclination β; the following criteria are valid:

[0067] beta 1 = α s / 2

[0068] beta 2 = α s

[0069] beta 1 is the sun side K relative to the irradiated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com