Laboratory exhaust treatment device

A waste gas treatment device and laboratory technology, applied in the field of laboratory equipment, can solve problems such as aging of rubber products, difficulty in discharging toxic and harmful gases, and affecting environmental air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

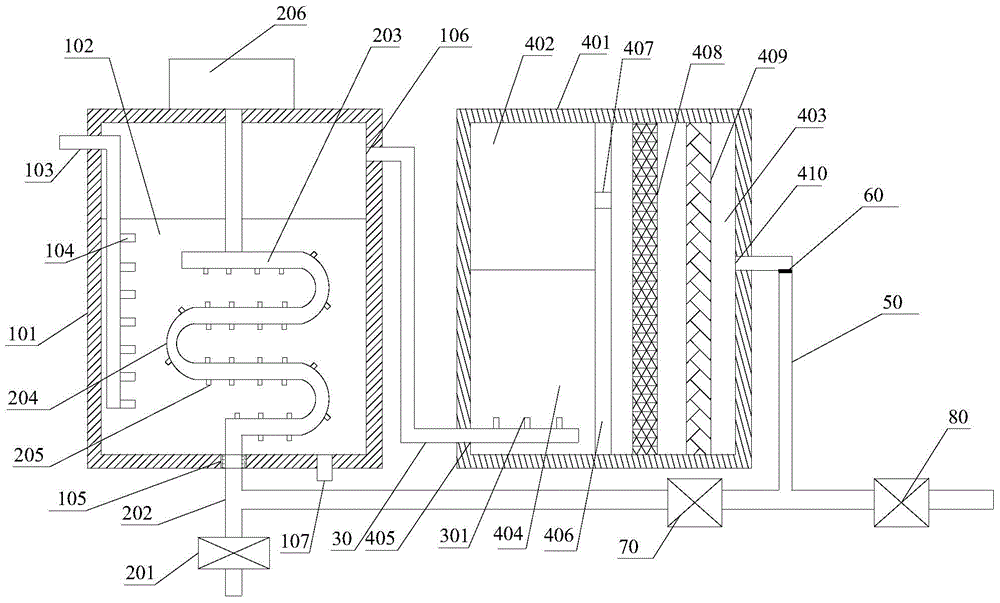

[0016] refer to figure 1 , the present invention proposes a laboratory exhaust gas treatment device, including an air intake device, a first purification device, a second purification device, a connecting pipe 30, an air outlet pipe 50, a gas detector 60, a controller, and a driving device 206, wherein:

[0017] The first purification device comprises a first casing 101 and a liquid inlet pipe 103. The first purification liquid 102 (water is selected in this embodiment) is provided in the first casing 101, and one end of the liquid inlet pipe 103 is connected to the The purification liquid tank outside the body 101 is connected, and the other end is sealed and extends into the bottom of the first purification liquid 102. The liquid inlet pipe 103 is located below the liquid surface of the first purification liquid 102. A nozzle 104 is provided in the nozzle 104. A first flow valve is arranged in the nozzle 104. , the first flow valve is connected to the controller; the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com