Catalytic cracking catalyst, preparation method therefor and application thereof

A catalytic cracking and catalyst technology, applied in the fields of chemical industry and catalytic cracking, can solve the problems of increasing the complexity of the catalyst preparation process and increasing the cost of catalyst preparation, and achieve the effects of good industrial application prospects, good bonding performance and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of catalytic cracking catalyst, it comprises the following steps:

[0050] 1. Preparation of ZSM-5-based hierarchical porous molecular sieve:

[0051] Under stirring conditions, prepare the following two working solutions respectively:

[0052] Solution I: a uniform solution prepared from 0.14g of aluminum sulfate, 0.87g of sodium hydroxide and 10g of deionized water;

[0053] Solution II: a solution prepared from 17.27g silica sol, 0.40g tetrapropylammonium bromide and 10g deionized water;

[0054] After mixing solution I and solution II uniformly, crystallize at 80°C for 24 hours; in the above mixed solution obtained by mixing solution I and solution II uniformly, M 2 O: X 2 o 3 、YO 2 , (TPA) 2 O, H 2 The molar ratio of O is 50:1:550:3.6:7000;

[0055] Then, the temperature was raised to 180°C to continue crystallization for 24 hours; after the reaction product was suction filtered, washed, and dried...

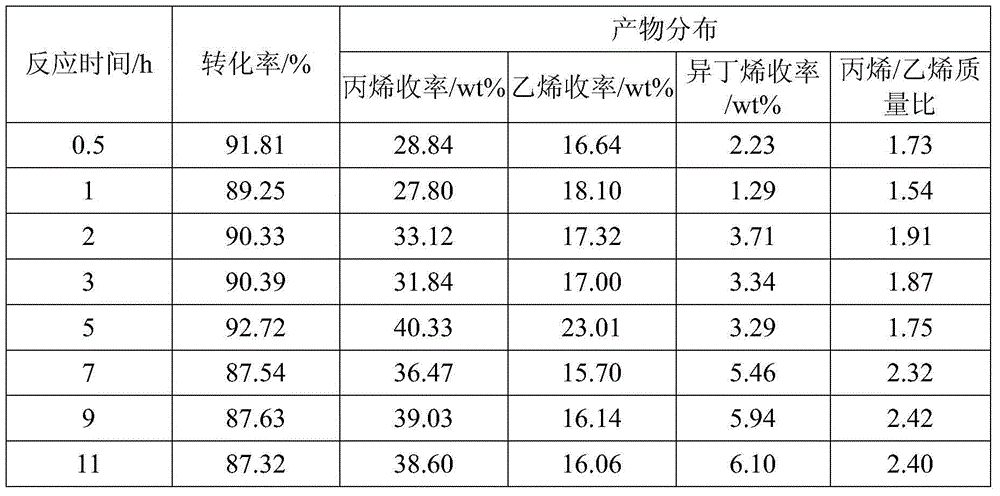

Embodiment 2

[0063] The present embodiment provides a kind of preparation method of catalytic cracking catalyst, and its difference with embodiment 1 only is that the present embodiment adopts commercial ZSM-5 molecular sieve (SiO 2 with Al 2 o 3The molar ratio is 35, the grain size is 3-5μm) as the active component.

Embodiment 3

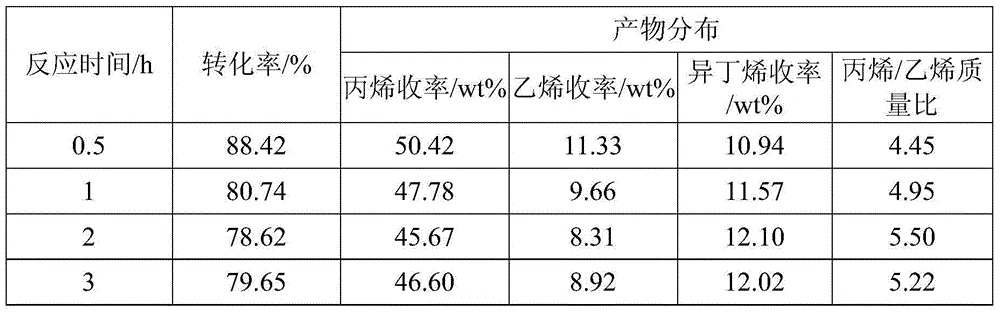

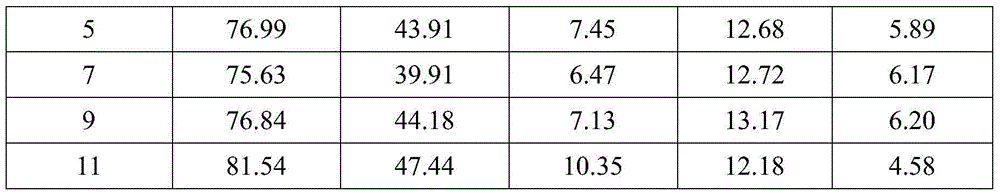

[0065] This embodiment provides the application of the catalytic cracking catalyst prepared in Example 1 in the preparation of propylene from carbon tetraolefin raw materials, which includes the following steps:

[0066] The catalytic cracking catalyst prepared in Example 1 was hydrothermally treated at 800° C. and 100% steam for 4 hours to obtain a hydrothermally treated catalyst;

[0067] The above-mentioned catalyst and carbon tetraolefin raw material (the mixed carbon tetraolefin raw material produced by Shenghua Refinery in Dongying, Shandong, whose composition is shown in Table 1) after hydrothermal treatment are carried out catalytic cracking reaction on a fixed bed micro-reactor, and the reaction temperature is 550°C, and the weight hourly space velocity is 5.2h -1 , The reaction time is 0.5h, 1h, 2h, 3h, 5h, 7h, 9h, 11h respectively, and the reaction results are shown in Table 2.

[0068] Table 1

[0069] components

Composition, wt%

Isobutane

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap