Outer mould of inequilateral lining core mould of rectangular special-shaped steel tube

A special-shaped steel pipe, unequal technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

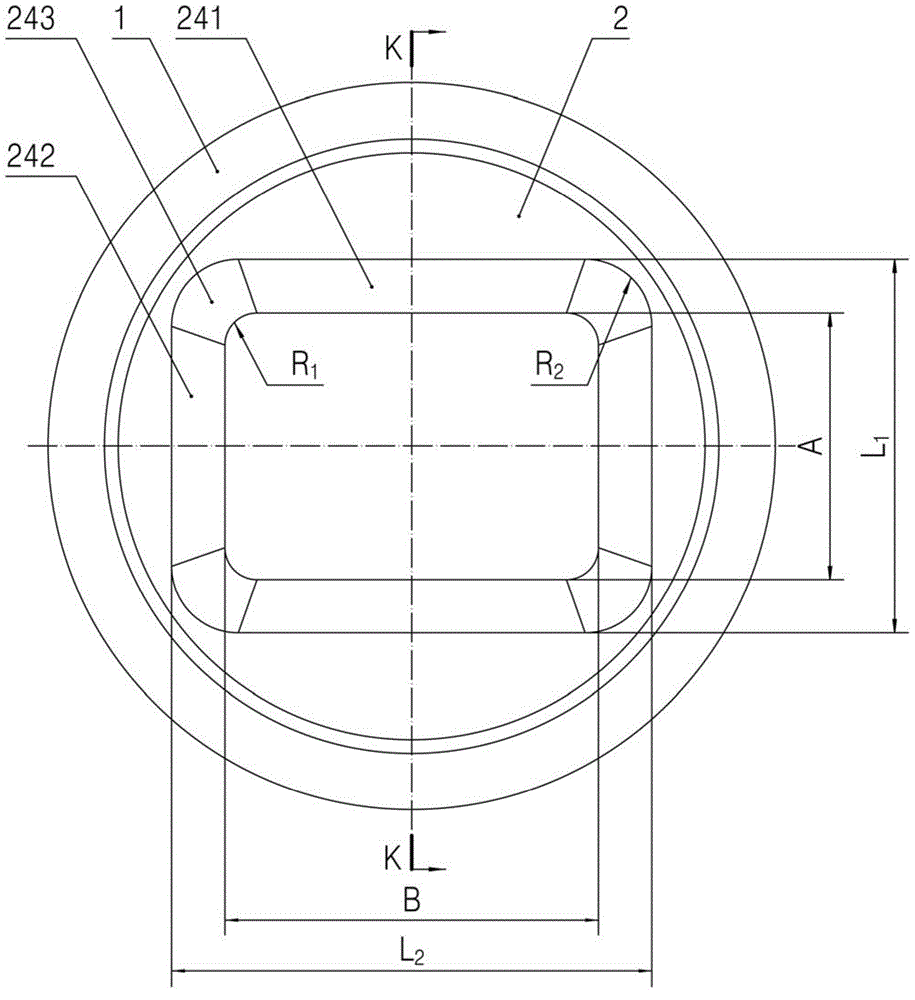

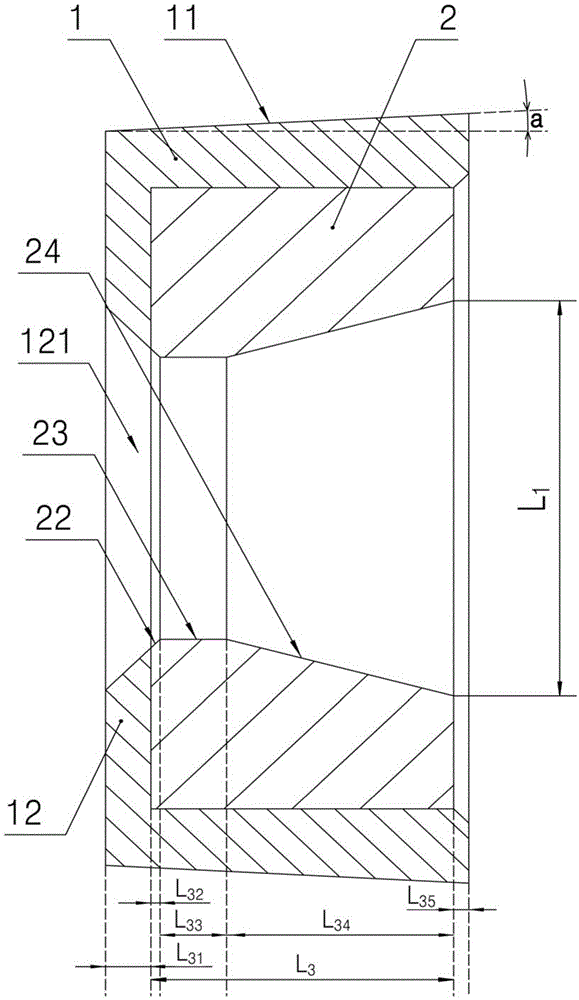

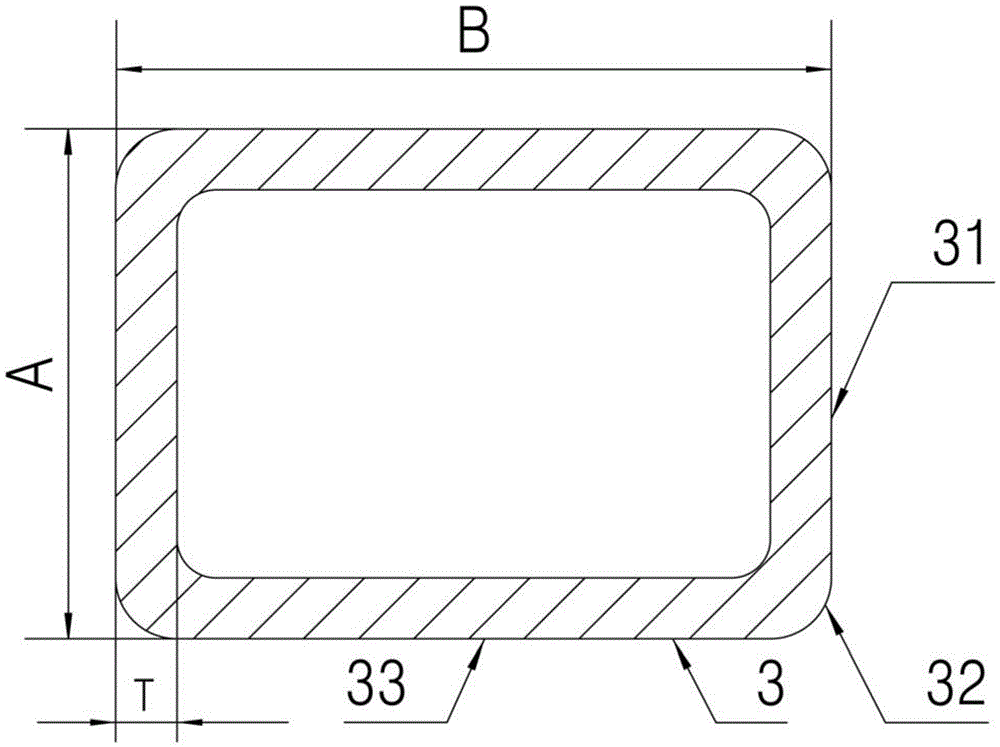

[0022] Below in conjunction with accompanying drawing, describe in detail a kind of production such as described in the present invention image 3 The specific implementation of the outer mold of the unequal sides lined mandrel of the rectangular special-shaped steel pipe 3 shown.

[0023] Such as figure 1 and figure 2 As shown, the outer mold of the rectangular special-shaped steel pipe with unequal sides lining mandrel described in the present invention includes: an insert 1, and a mold core 2 arranged in the insert 1, and the mold core 2 is provided with a pulley through the mold core. The drawing hole, the drawing hole includes: an inlet section 24, a sizing section 23 and an outlet section 22 connected in sequence, one end of the insert 1 is provided with an opening for installing the mold core 2, and the mold core 2 is embedded in the insert 1 from the opening, and the other end of the insert 1 is provided with an end wall 12, and the end wall 12 is provided with an o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap