Drawing die structure with double press materials feeding and punching method utilizing drawing die structure

A drawing die and pressing plate technology, applied in the field of stamping die, can solve the problems of increasing the development cost of the die, affecting the progress of product sample delivery, wrinkling and stacking of the waistline of the tail door frame, etc., to reduce the number of debugging and Difficulty, ensure product appearance quality, improve the effect of sealing surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

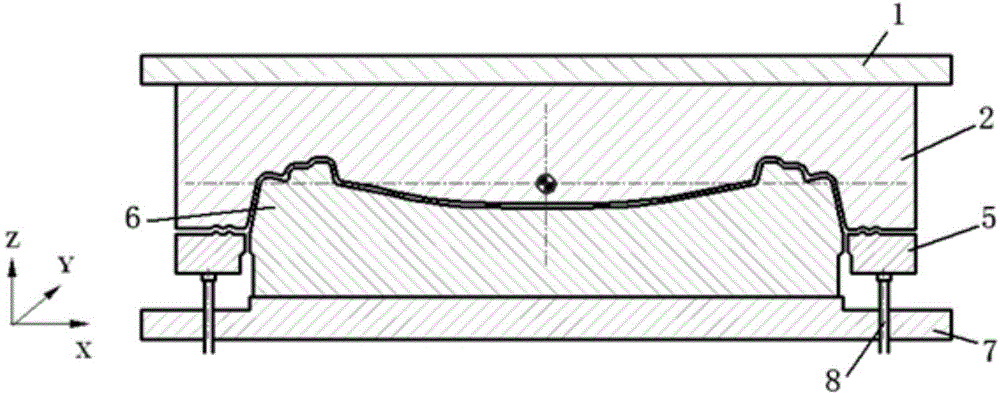

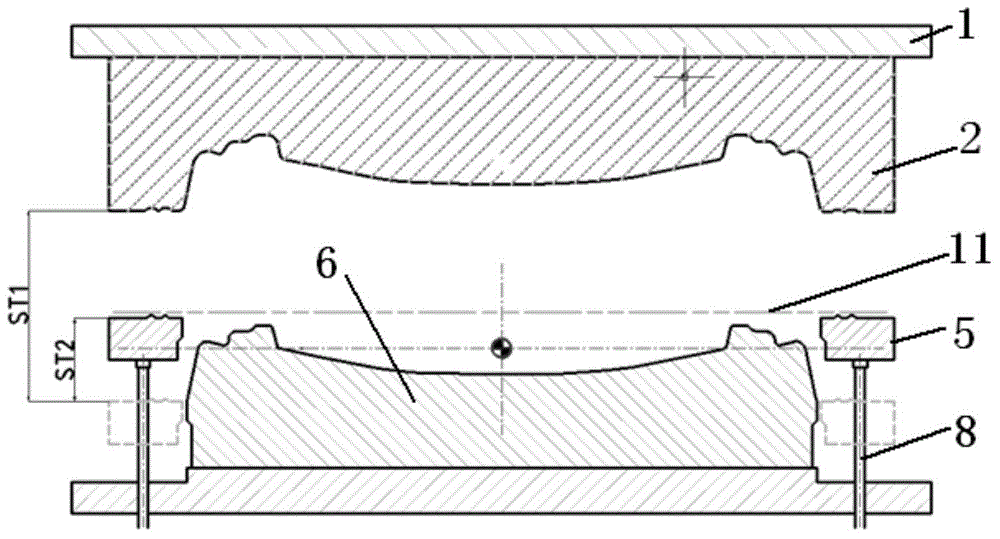

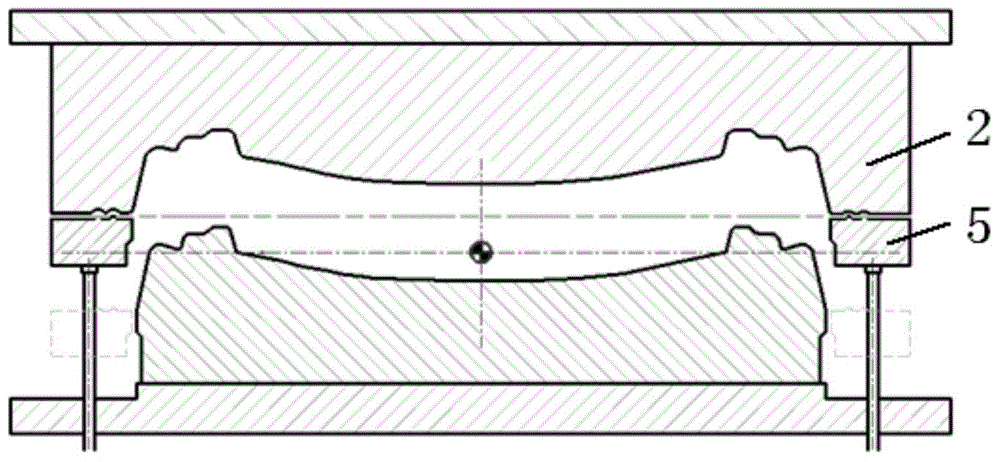

[0037] The following will be combined with Figure 1-20 The technical solution of the present invention is described in detail.

[0038] Traditional drawing die structure and its implementation process: such as figure 1 As shown, among them, the traditional drawing die is composed of an upper die and a lower die, wherein the upper die is composed of an upper die base 1 and a die 2, and the upper die base 1 and the die 2 are connected by fasteners. The movement direction of the slider drive is ±Z direction during the stamping process, the movement of the two is consistent, and the die is an integral structure; the lower die is composed of the punch 6, the blank holder 5 and the lower die seat 7, wherein the punch 6 is fixed on the lower mold base 7 by fasteners, and is in a static state during the stamping process; the blank holder 5 drives the ejector rod 8 through the lower slider of the stamping machine, so that the movement direction of the blank holder 5 during the stampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com