CNC key tooth flower automatic punching machine

A punching machine and key technology, which is applied in the field of automatic punching machines for CNC key teeth, can solve the problems of not easy to ensure the key is clamped in place, inaccurate angle of reverse reset, affecting the quality of key teeth, etc. The effect of discharging, ensuring accuracy, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

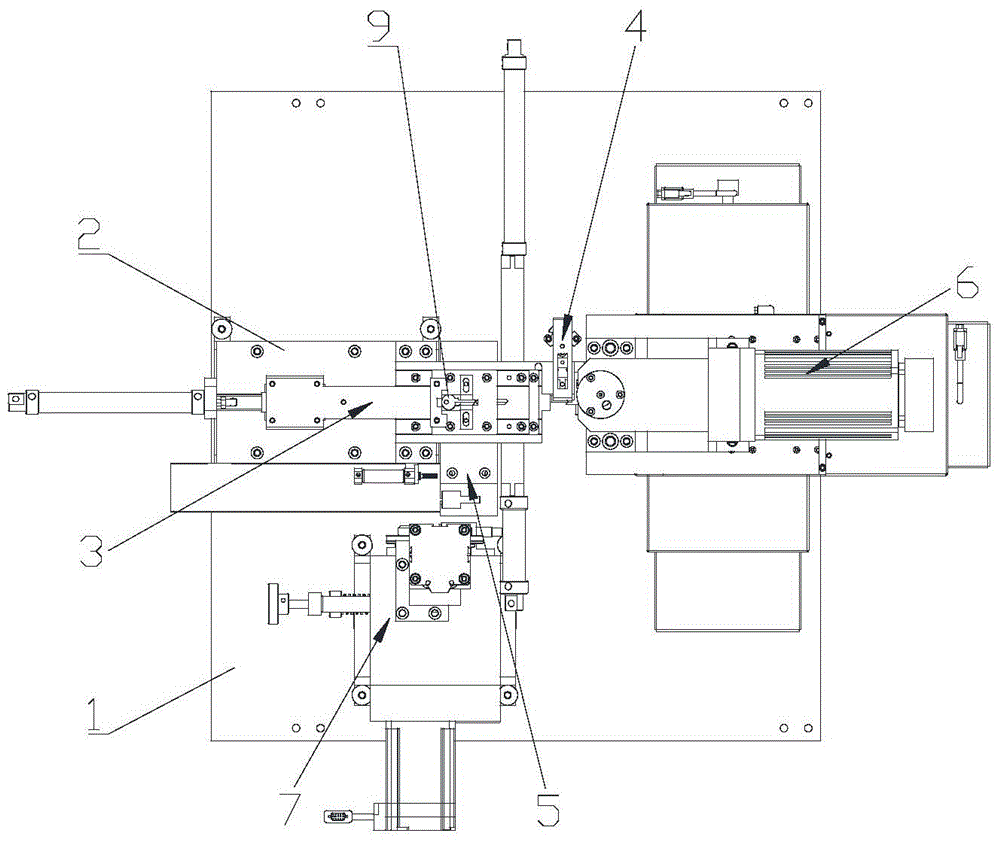

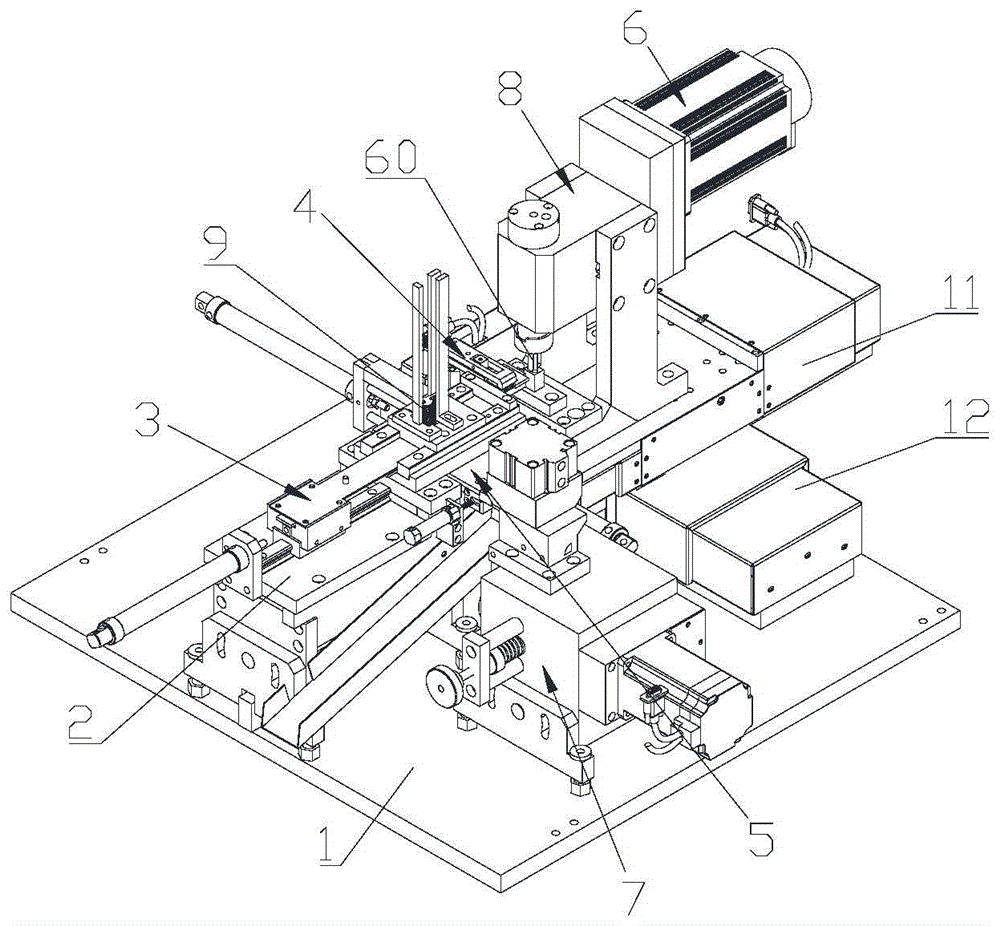

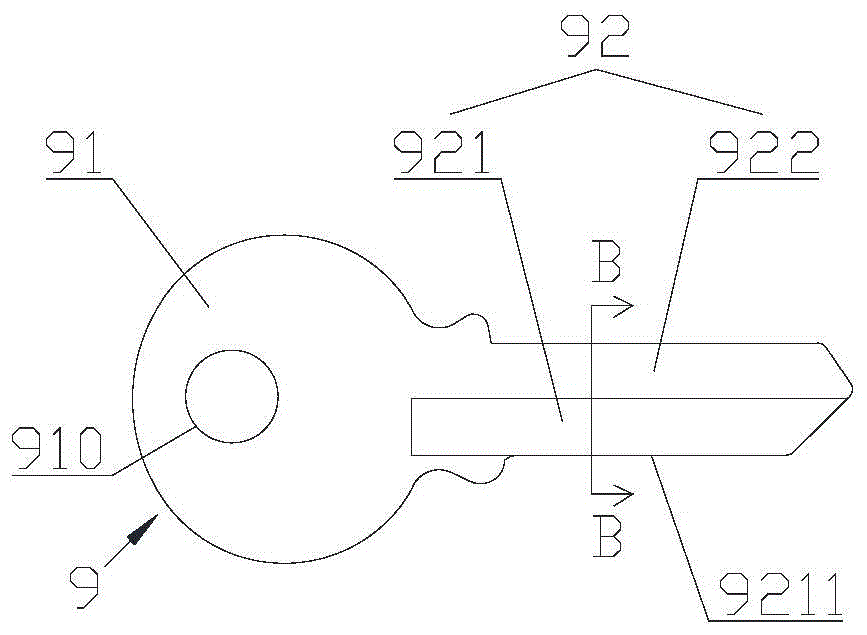

[0047] The present invention provides a kind of digital control key tooth flower automatic punching machine, such as figure 1 and figure 2 As shown, it includes a frame 1, a feeding mechanism and a tooth punching mechanism. The feeding mechanism includes a first bracket 2, a feeding assembly 3, a clamping assembly 4 and a discharging assembly 5. The first bracket 2 is installed on the frame 1, and the clamping The tightening assembly 4 is fixed on the front end of the first bracket 2, the discharge assembly 5 is arranged on the first bracket 2 and is located behind the clamping assembly 4, and the feeding assembly 3 drives the key 9 to be processed from the back to the front relative to the first bracket 2 To the clamping assembly 4, and drive the processed key 9 from front to rear relative to the first bracket 2 to the discharge assembly 5, the punching mechanism includes a drive assembly 6 and a punching knife 60, and the drive assembly 6 is installed through the feed carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com