Turnable belt conveyer

A conveyor belt and belt technology, which is applied in the field of belt conveyors that can turn, can solve the problems such as the inability of the conveyor to turn and increase the cost of the conveyor, and achieve the effects of large turning angle, simple and reasonable structure, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

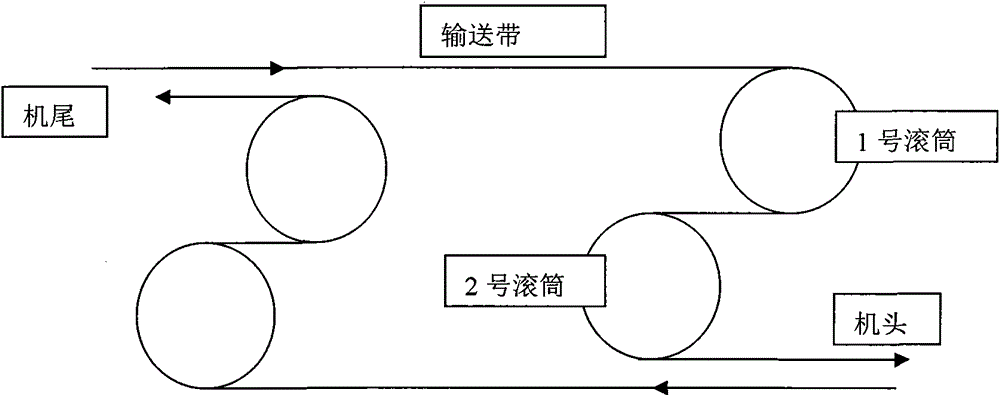

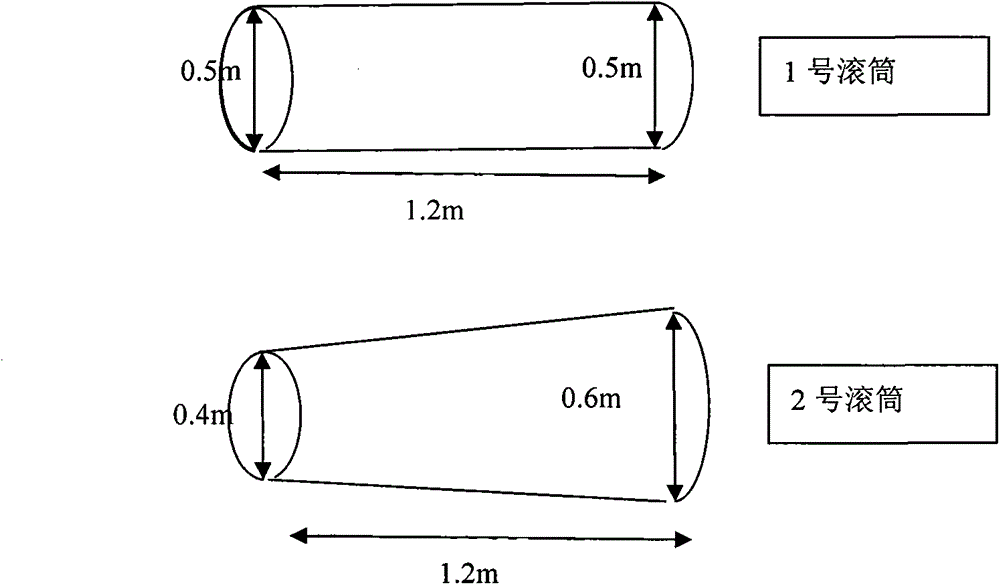

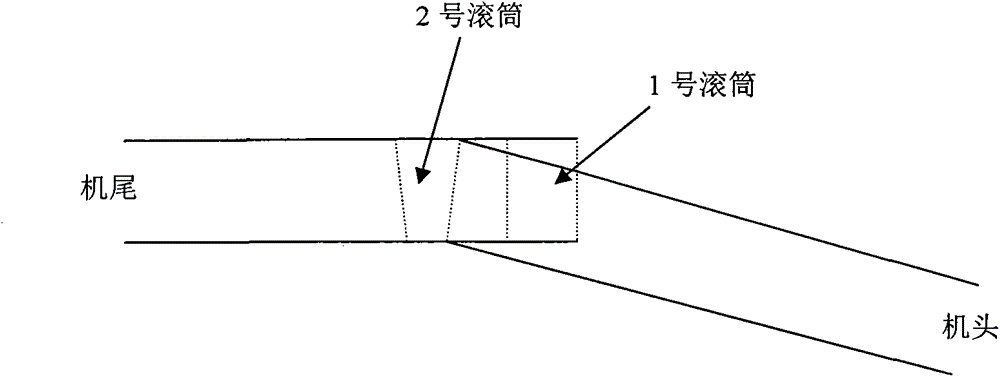

[0008] The present invention will be further described below in conjunction with the accompanying drawings. Embodiment The drum is generally made of metal, and the belt is generally made of rubber. During the implementation process, the goods are transported from the tail of the machine to the top of the No. 1 roller by the belt, and the goods will automatically fall onto the belt at the nose of the machine, and the goods will be transported away by the traction of the machine head. exist figure 2 The side view of No. 1 and No. 2 rollers is shown in . The two ends of the No. 2 roller are of different thicknesses, which can realize turning. image 3 As a top view, it can be seen that the goods on the No. 2 drum will not fall directly, but will fall to the head belt, and a baffle or funnel can be added here to make the goods fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com