A method for extracting p-chlorobenzoic acid in enone wastewater

A technology of p-chlorobenzoic acid and sodium chlorobenzoate, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate salts, etc., can solve problems such as environmental pollution, high pressure on wastewater treatment, and achieve high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated by the following examples: According to the following examples, the present invention can be better understood. However, those skilled in the art can easily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the present invention, and should not and will not limit the present invention described in the claims.

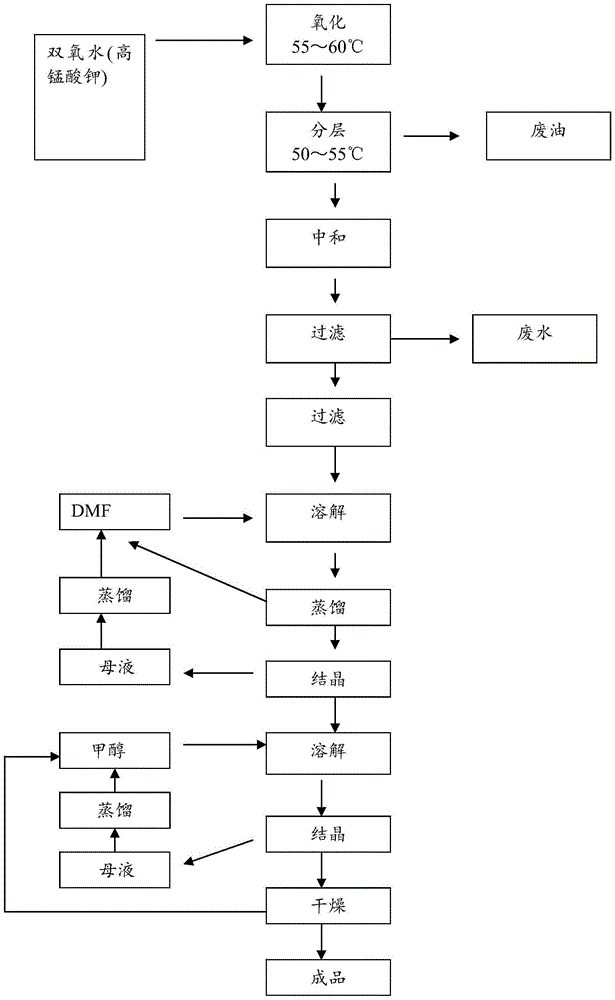

[0019] ginseng figure 1 Shown, in the present embodiment, the method for extracting p-chlorobenzoic acid in enone waste water comprises:

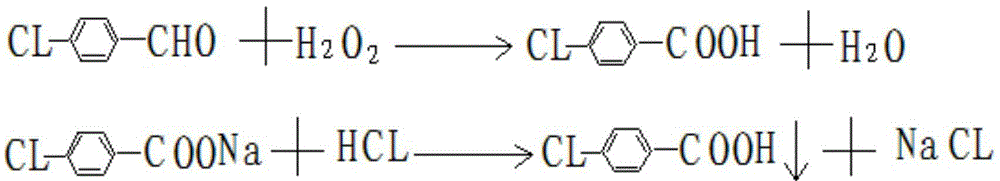

[0020] (1), by means of oxidation, the sodium p-chlorobenzylmethoxide in the enone wastewater is oxidized into sodium p-chlorobenzoate, the oxide compound that adopts in the oxidation process is preferably hydrogen peroxide or potassium permanganate, and the oxidation temperature is 55~60 ℃.

[0021] (2) Separating the bottom organic matter by layering, the temperature in the layering process is 50-55°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com