Rapid joint of precast concrete pile

A prefabricated concrete, fast technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problem that the connector can not solve the problem of sealing, loose combination, complex assembly process, etc., to improve the corrosion resistance and high docking accuracy , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Prefabricated Concrete Pile Quick Joint Cooperating with Steel Rod

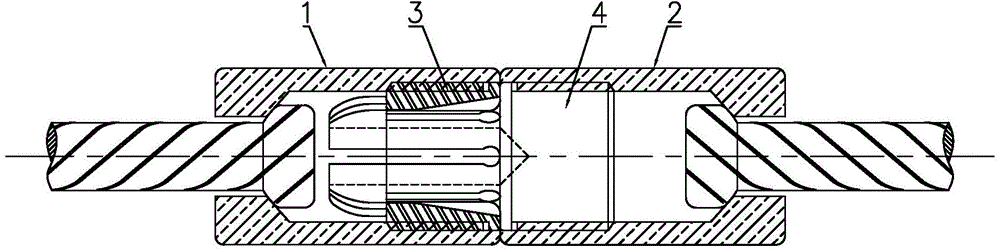

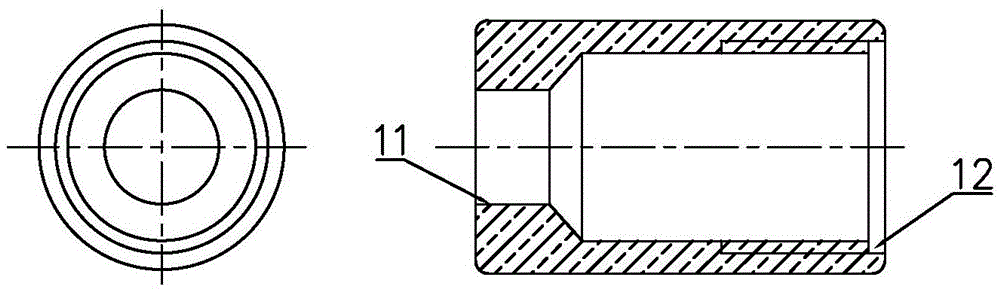

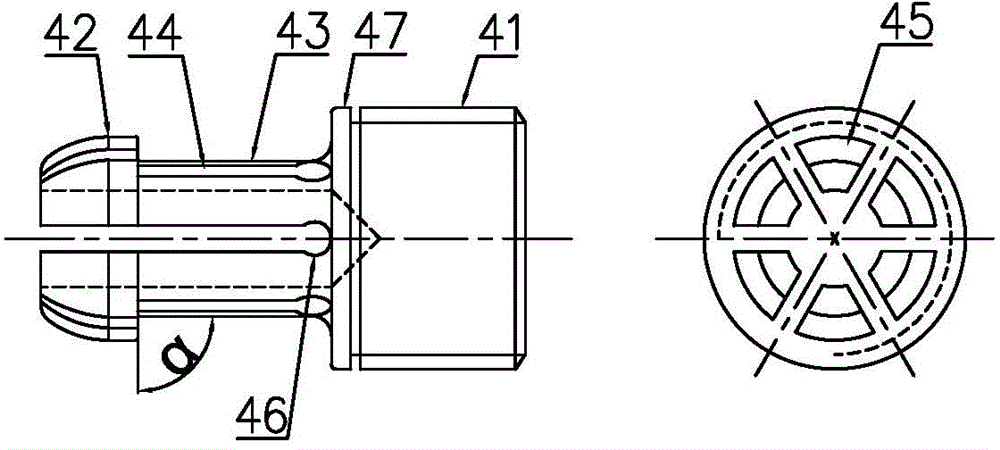

[0036] Such as Figure 1-4 As shown, a quick connector for prefabricated concrete piles includes a tension positioning sleeve I1 and a tension positioning sleeve II2. Both the tension positioning sleeve I1 and the tension positioning sleeve II2 are sleeve-shaped structures. The tension positioning sleeve The bottoms of I1 and the tensioning positioning sleeve II2 are provided with a limit end 11 capable of limiting the end of the steel bar inside, and also include a guide buckle 3 and a spring buckle pin 4. The tensioning positioning sleeve I1 is equipped with a There is an internal thread, the guide buckle 3 is a cylindrical ring, and the outside of the guide buckle 3 is provided with an external thread that matches the internal thread of the tensioning positioning sleeve I1; the internal thread of the tensioning positioning sleeve II2 is provided. The spring reverse buckle pin 4 include...

Embodiment 2

[0042] Embodiment 2 Prefabricated Concrete Pile Quick Connector Cooperating with Rebar

[0043] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that the bottoms of the tensioning positioning sleeve I1 and the tensioning positioning sleeve II2 are provided with threaded through holes to form a limit end, and the ends of the rebar are provided with external threads, and Screw into the threaded through hole. Other structures and principles are the same as those in Embodiment 1.

Embodiment 3

[0044] Embodiment 3 Prefabricated Concrete Pile Quick Connect Cooperating with Steel Strand

[0045] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: the limiting end of this embodiment is a tapered hole with a large mouth facing inward, and a steel strand anchor head with a tapered outer surface is arranged in the tapered hole 5. The outer surface of the steel strand anchor head 5 fits with the tapered hole, the steel strand anchor head 5 is limited in the tapered hole, and the steel strand anchor head 5 is provided with a steel wire retaining spring 6, the steel strand anchor The head 5 is set and fixed on the end of the steel strand to realize the connection between the steel strand and the tension positioning sleeve I1 and the steel strand and the tension positioning sleeve II2. Other structures and principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com