Twining communication dress rehearsal wire and manufacturing method thereof

A manufacturing method and core wire technology, which are used in the manufacture of cables/conductors, cables with double-stranded/quad-stranded, insulation of conductors/cables, etc. It can save raw materials, improve the quality of cables, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

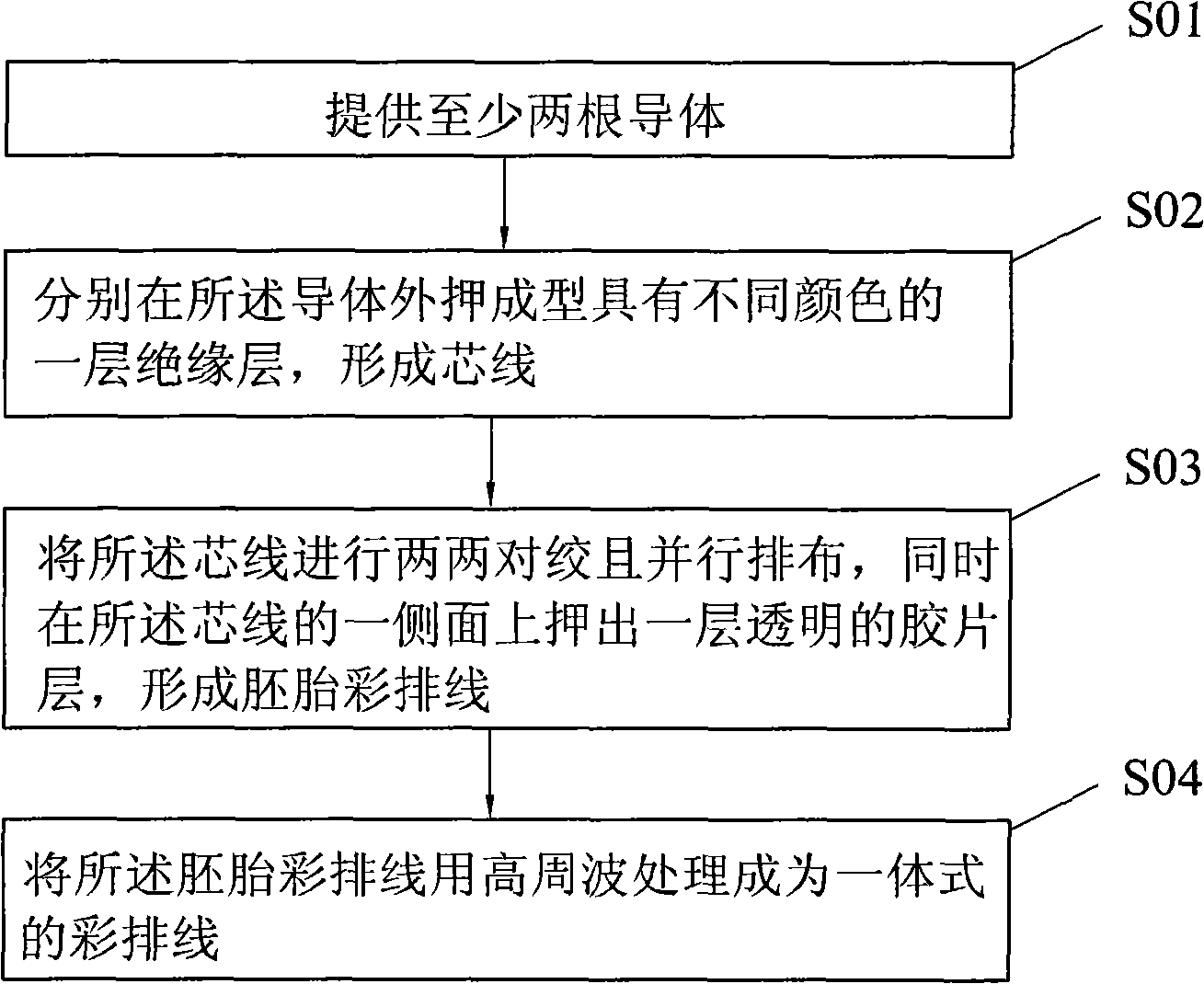

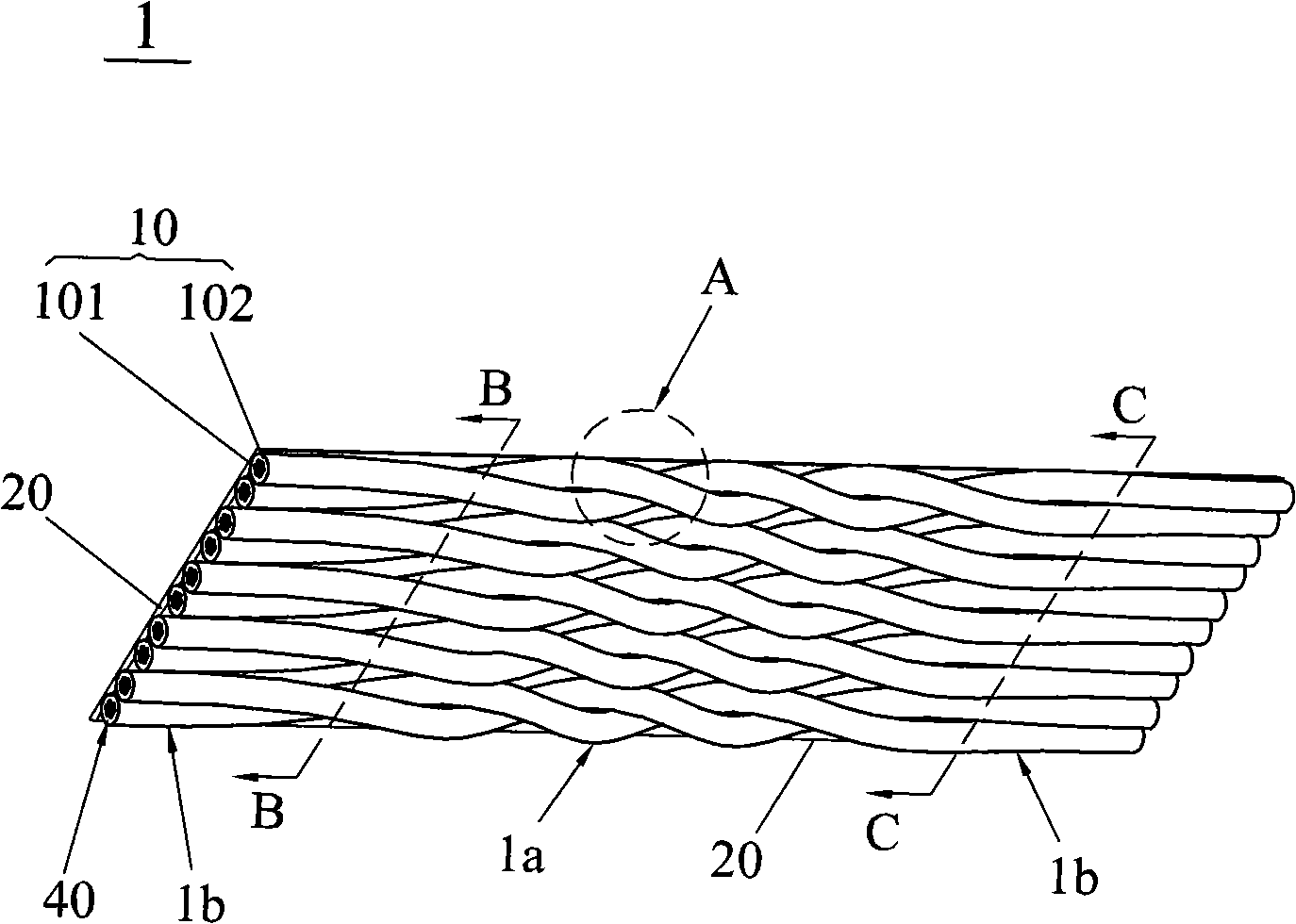

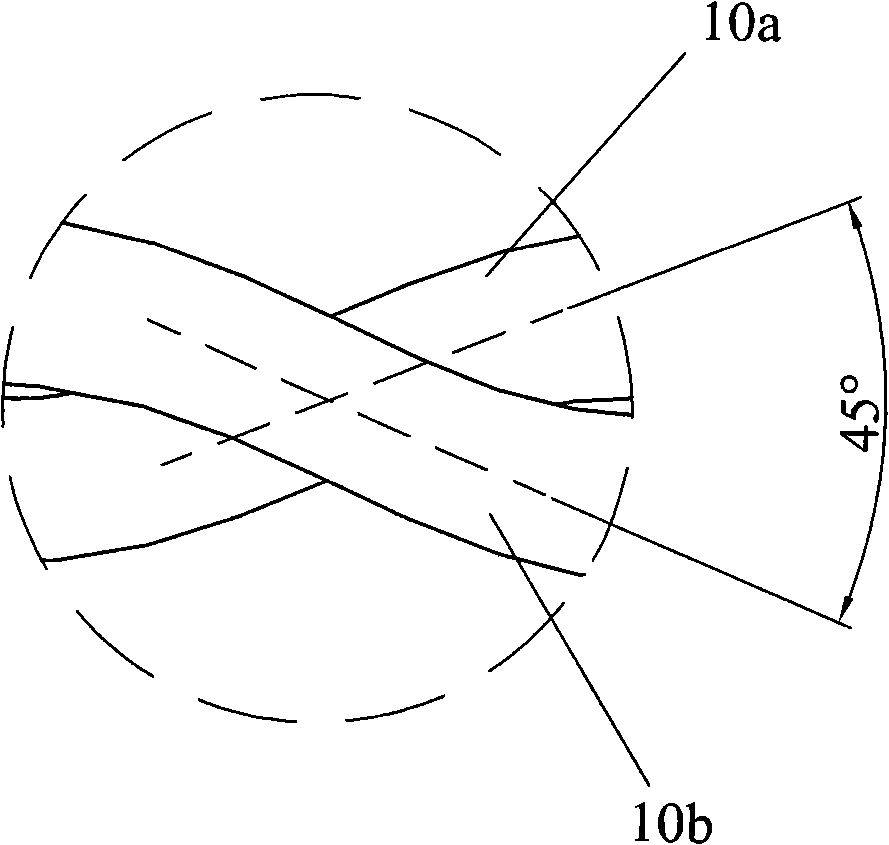

[0022] Such as figure 1 As shown, the method for manufacturing a paired communication rehearsal wire of the present invention includes the following steps: (S01) providing at least two conductors; (S02) forming a layer of insulating layer with different colors on the outside of the conductors to form a core wire; ( S03) Twisting the core wires in pairs and arranging them in parallel, and simultaneously extruding a layer of transparent film layer on one side of the core wires to form an embryo rehearsal wire; (S04) using the embryo rehearsal wire High frequency processing becomes an all-in-one rehearsal line. Specifically, the core wires of the pair-twisted communication rehearsal wire are twisted at an angle of 45° in pairs, that is, the two core wires are crossed at 45° and twisted in pairs, so that the electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com