Pedal type mortar pump

A mortar pump, foot-operated technology, applied in the direction of variable displacement pump components, pumps, piston pumps, etc., can solve the problems of deteriorating the working station environment, consuming a lot of man-hours, wasting raw materials, etc., and purifying the working station environment and structure. Simple, material-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

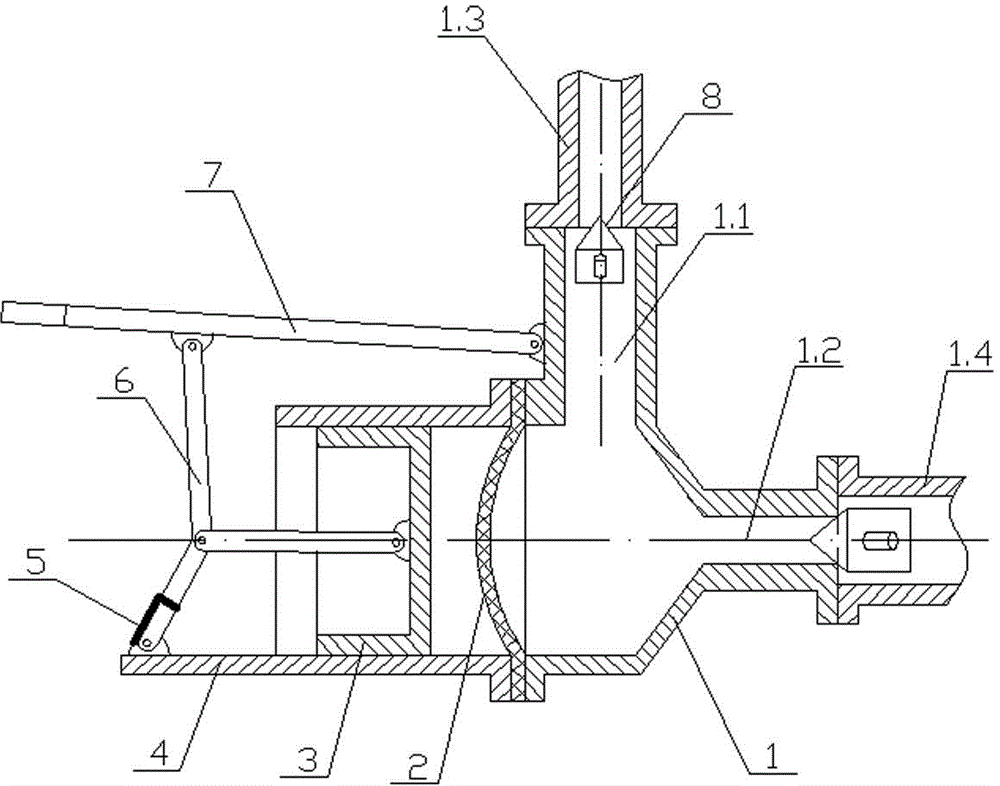

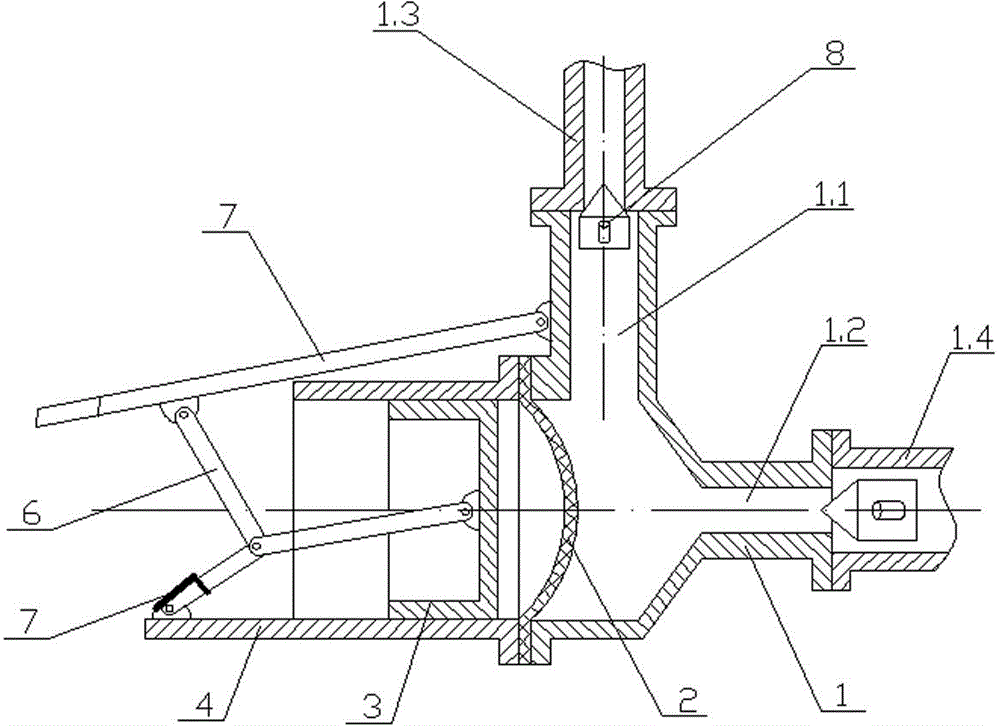

[0015] The foot-operated mortar pump shown in the drawings is a horizontal structure, which includes a pump body 1, a diaphragm 2, a piston 3, a cylinder body 4, a torsion spring 5, a connecting rod 6, a lever 7 and a taper plug 8. The pump body 1 is a three-way shell member, the upper inlet 1.1 is vertically communicated with the side outlet 1.2, and the prone outlet 1.2 is coaxial with the large hole end on the other side of the pump body 1 . Lever 7 is a rod member carrying power, and one end is hinged on the upper outer wall of the large hole end of pump body 1 . The cylinder 4 located on the left side of the pump body 1 is equipped with a piston 3 driven by the connecting rod 6. The diaphragm 2 is fixedly connected between the end face of the cylinder 4 and the large hole end of the pump body 1. The diaphragm 2 with an arc-shaped e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com