Centripetal type compressor

A compressor, axial technology, applied in the field of impeller machinery, can solve the problems of increasing system instability, increasing manufacturing costs, large axial force, etc., and achieving the effects of improving work efficiency, avoiding vibration, and reducing gap loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The centripetal compressor involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023]

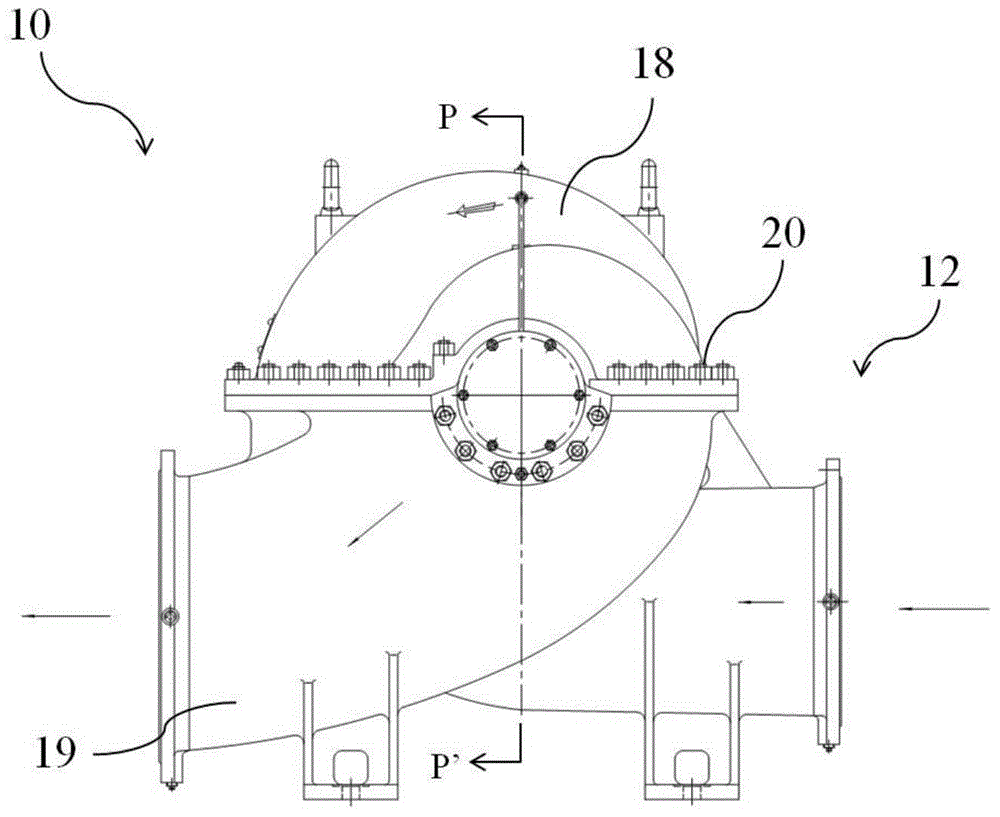

[0024] figure 1 It is the structural representation of the centripetal compressor of embodiment;

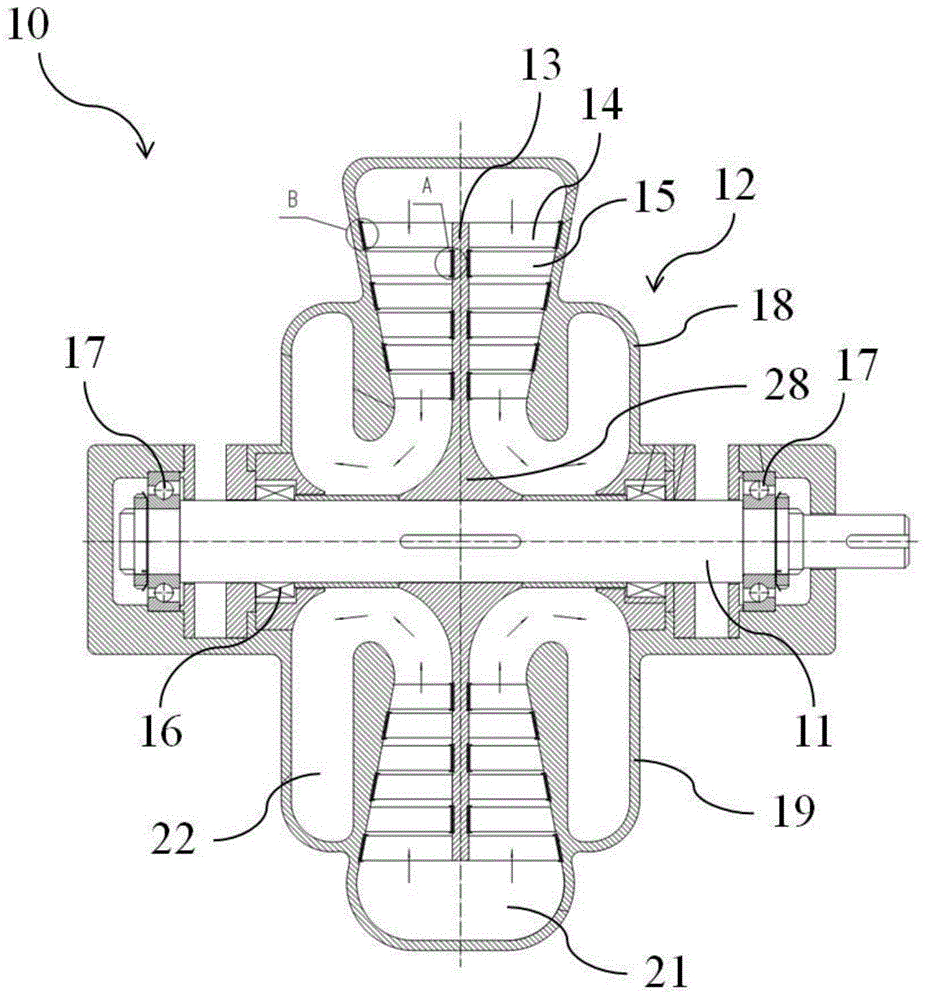

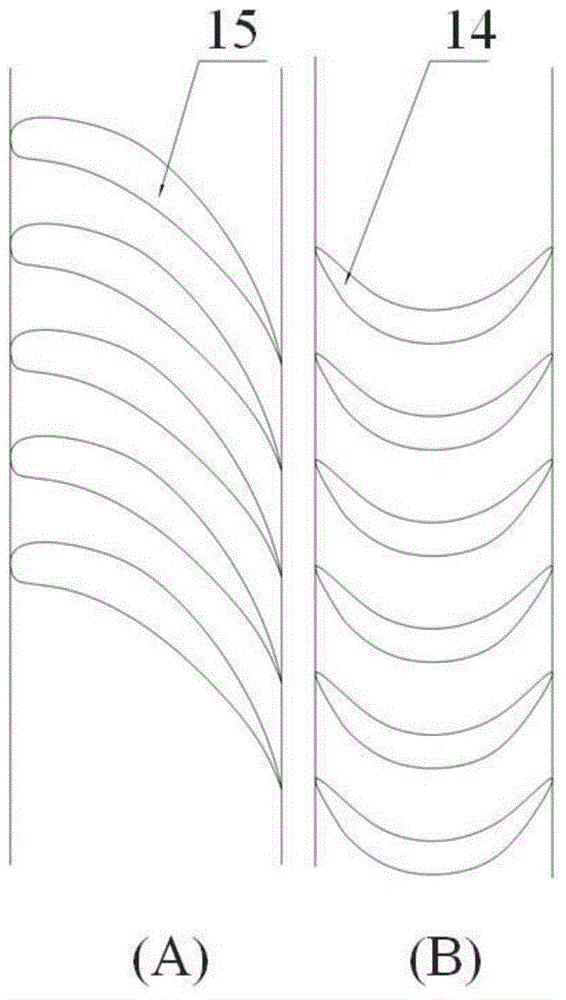

[0025] figure 2 yes figure 1 The cross-sectional view of the P-P' direction.

[0026] Such as figure 1 , 2 As shown, the centripetal compressor 10 includes a rotating shaft 11 , a casing 12 , a disc 13 , multiple sets of moving blade cascades 14 , multiple sets of stationary blade cascades 15 and a sealing body 16 .

[0027] The rotating shaft 11 is rotatably fixed on the bearings 17 at both ends, and drives the wheel disc 13 to rotate. The rotating shaft 11 is externally connected to a motor or other prime movers (not shown in the figure).

[0028] The casing 12 is used to protect the centripetal compressor 10 . In this embodiment, the casing 12 includes an upper casing 18 and a lower casing 19 , and the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com