Novel Co<2> multi-stage throttle frost valve

A throttling antifreeze valve, CO2 technology, applied in the field of throttling valves, can solve the problems of valve body and pipeline behind the valve freezing, low fluid temperature, etc., achieve the effects of alleviating impact wear, reducing labor intensity, and improving equipment maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

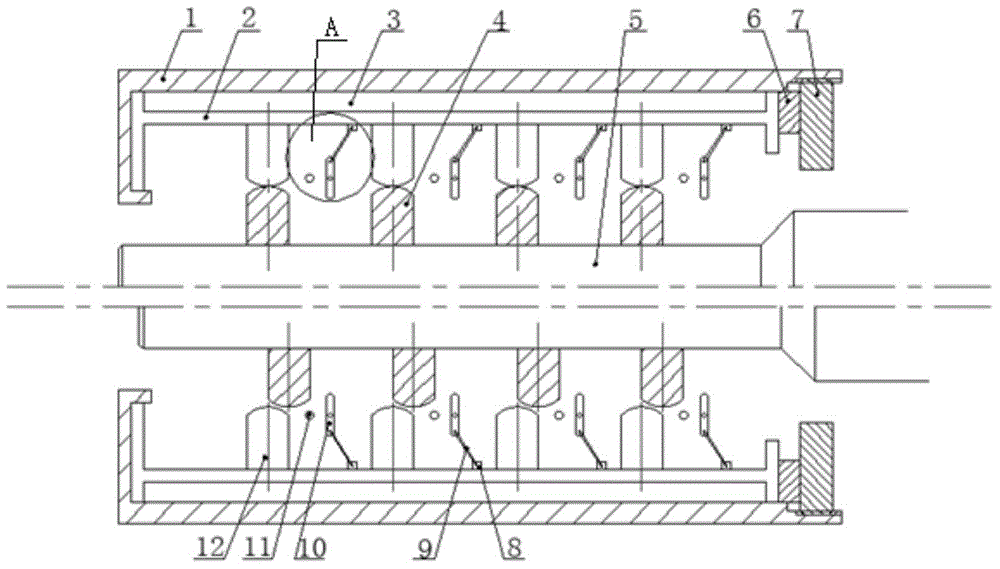

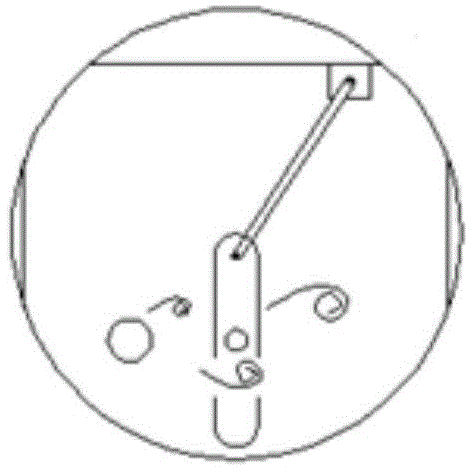

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Depend on figure 1 and figure 2 As shown, a new type of CO 2 The multi-stage throttling antifreeze valve includes a valve body 1, a valve cylinder 2, a valve core 5 and a friction heating system, wherein the valve cylinder 2 is set inside the valve body 1, the valve core 5 is set inside the valve cylinder 2, and the valve cylinder 2. Several stages of valve cylinder components 12 are provided on the inner wall, and several stages of valve core components 4 are provided on the outer wall of the valve core 5 to cooperate with the several stages of valve cylinder components 12 respectively. The valve core components 4 and the valve cylinder components 12 cooperate To form or close the throttling channel, the friction heating system includes an annulus 3 for containing heat transfer medium and several sets of friction devices, the annulus 3 is arranged between the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com