Tank connecting structure of no-header plate heat exchanger

A heat exchanger and box plate technology, applied in the field of connection structure, can solve the problems of occupying space and difficult to achieve miniaturization, and achieve the effects of material saving, improving pressure resistance and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Next, embodiments of the present invention will be described based on the drawings.

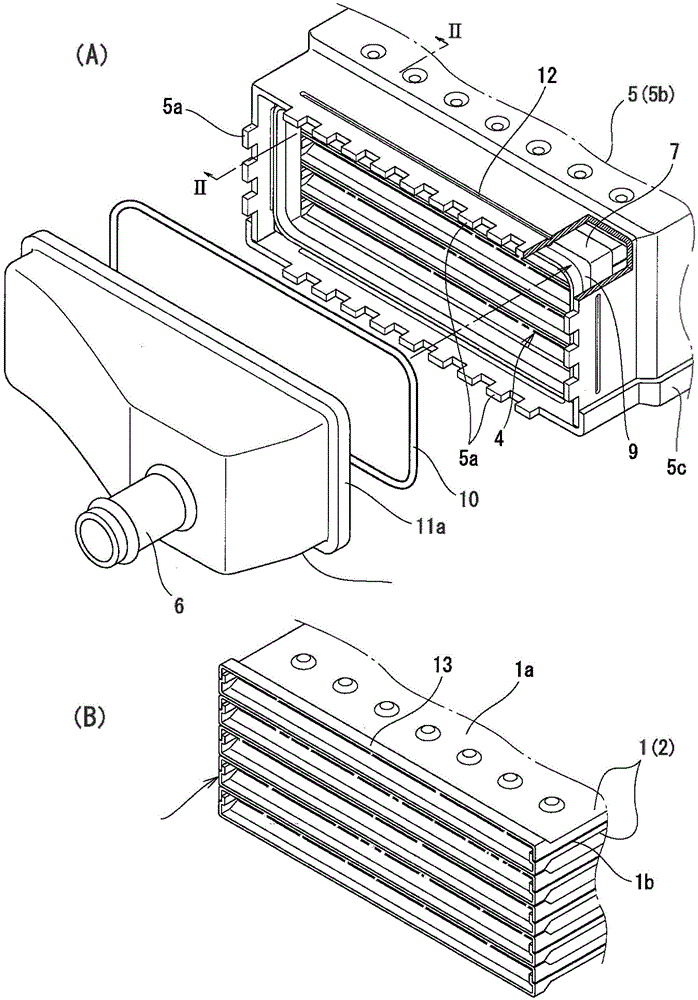

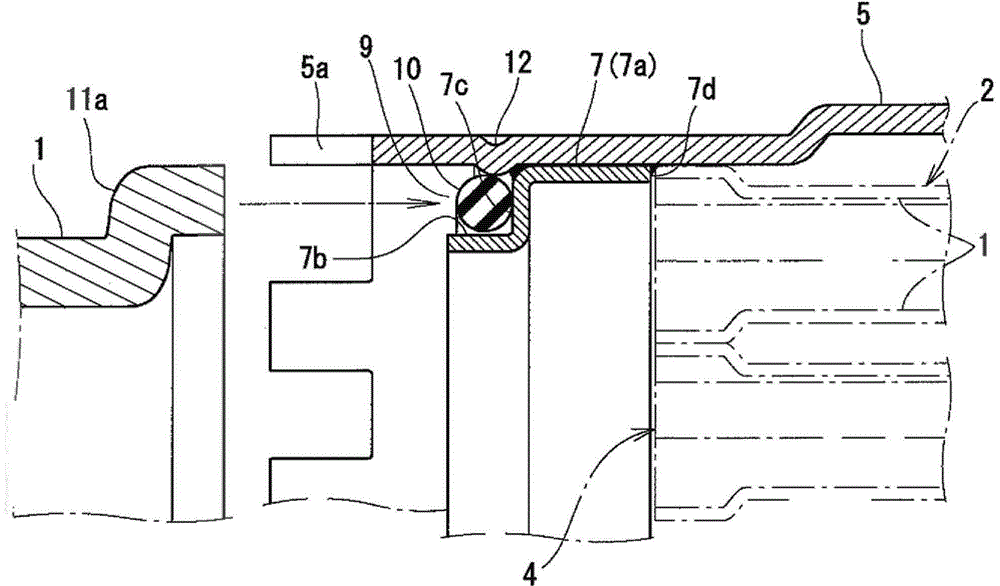

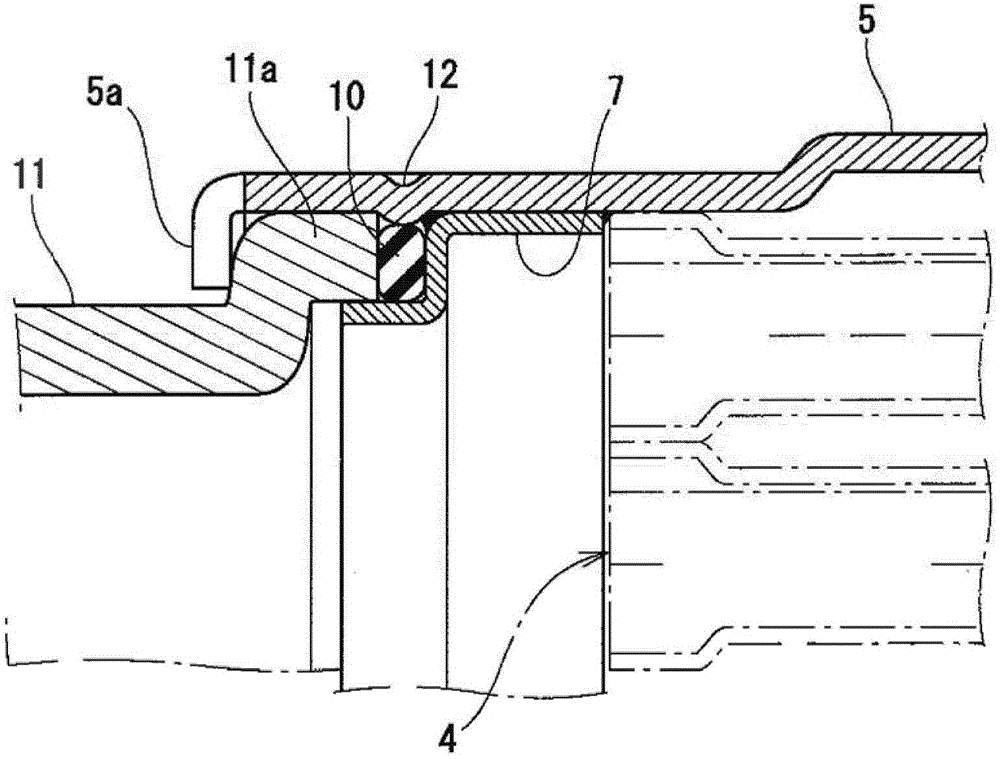

[0081] This heat exchanger has a core 4 composed of a laminated body of a plurality of flat tubes 2, a shell 5 covering the outer periphery of the core 4, a tank support 7 connected to the inner periphery of the end of the shell 5, a seal 10, and a tank. Subject 11.

[0082] Such as figure 1 As shown in (B), in each of the flat tubes 2 constituting the core 4 , a pair of groove-shaped plates 1 have their groove bottoms 1a facing each other, and their side walls 1b are fitted into each other. Moreover, the bulging part 3 which bulges outward in the groove bottom direction is provided in both opening end parts.

[0083] The respective flat tubes 2 form a core 4 by contacting each other with their bulging parts 3 and being laminated. The first fluid flows through the flat tubes 2 of the core 4 , and the second fluid flows through the gaps between the flat tubes 2 .

[0084] The case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com