Non-primary hole-by-hole blasting surface detonator and mounting and using method thereof

A non-priming, hole-by-hole technology, used in blasting, weapon accessories, fuzes, etc., can solve the problems of unsafe production and use, excessive consumption of explosives, and low accuracy, and achieve safe production and use, and reliable detonation and transmission. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

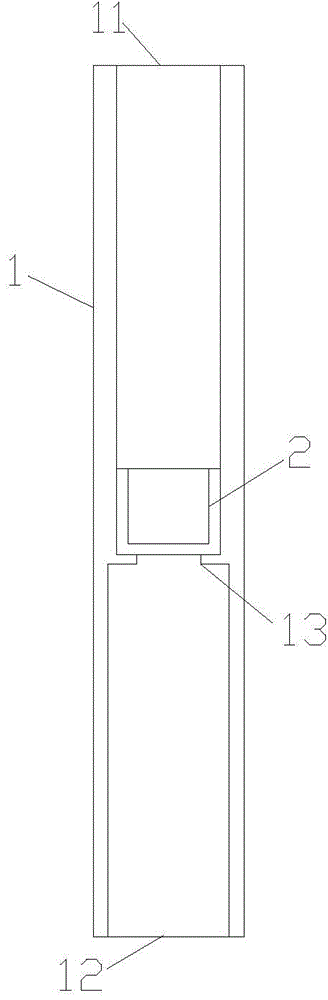

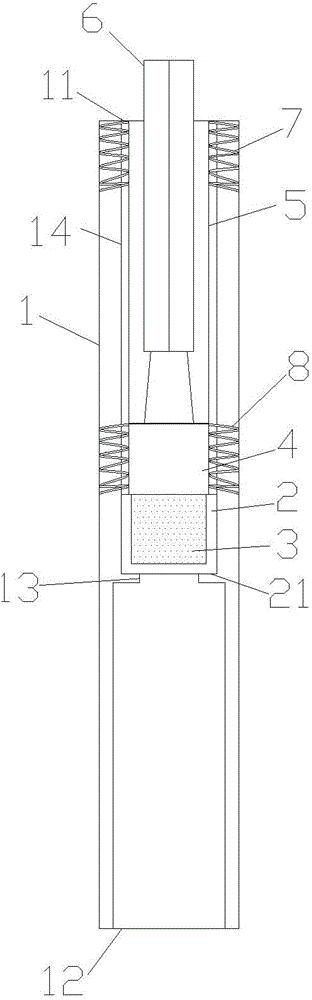

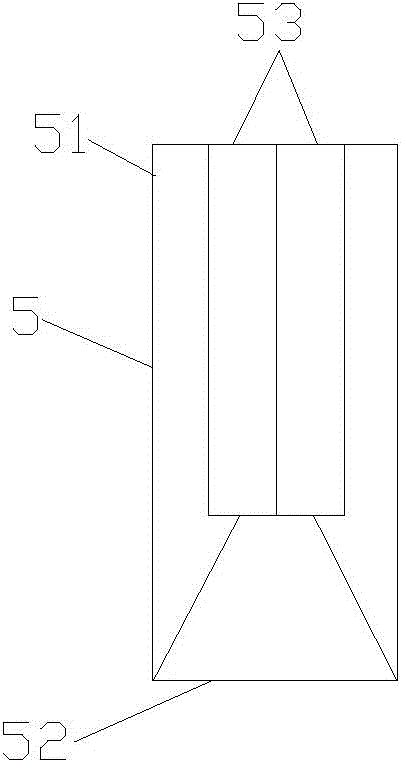

[0053] Such as figure 2 , 3 , 4, shown in 7, a kind of installation and the use method of hole-by-hole detonation surface detonator without priming charge, it is characterized in that following steps:

[0054] 1) Put the inner cap 2 with the opening facing upwards into the inside of the tube body 1 through the inlet 11 of the tube body 1, and pass 50Kg / cm 2 Pressurized and positioned at the position of the boss 13 in the middle of the tube body 1, the lower end 21 of the inner cap is in contact with the boss 13 in the tube body 1, and has an interference fit with the tube body 1;

[0055] 2) Put 0.20g of low-energy explosive 3 into the inner cap 2 through the inlet 11 of the pipe body 1, and the charge density is 0.65g / cm 3 , wherein the low-energy explosives 3 include passivated RDX0.14g, KCIO 3 0.06g;

[0056] 3) Install the single-core extension body 4 into the interior of the pipe body 1 through the inlet 11 of the pipe body 1. The bottom of the extension body 4 is in...

Embodiment 2

[0062] Such as figure 2 , 3 , Shown in 5 and 7, a kind of installation and the use method of hole-by-hole detonation surface detonator without priming charge are characterized in that following steps:

[0063] 1) Put the inner cap 2 with the opening facing upwards into the inside of the tube body 1 through the inlet 11 of the tube body 1, and pass 50Kg / cm 2 Pressurized and positioned at the position of the boss 13 in the middle of the tube body 1, the lower end 21 of the inner cap is in contact with the boss 13 in the tube body 1, and has an interference fit with the tube body 1;

[0064] 2) Put 0.30g of low-energy explosive 3 into the inner cap 2 through the inlet 11 of the pipe body 1, and the charge density is 0.95g / cm 3 , wherein low-energy explosives 3 include passivated PETN0.24g, KNO 3 0.06g;

[0065] 3) Put the three-core extension body 4 into the inside of the pipe body 1 through the inlet 11 of the pipe body 1, the bottom of the extension body 4 is in contact wi...

Embodiment 3

[0071] Such as figure 2 , 3 , Shown in 6 and 7, a kind of installation and the use method of hole-by-hole detonation surface detonator without priming charge are characterized in that following steps:

[0072] 1) Put the inner cap 2 with the opening facing upwards into the inside of the tube body 1 through the inlet 11 of the tube body 1, and pass 50Kg / cm 2 Pressurized and positioned at the position of the boss 13 in the middle of the tube body 1, the lower end 21 of the inner cap is in contact with the boss 13 in the tube body 1, and has an interference fit with the tube body 1;

[0073] 2) Put 0.25g of low-energy explosive 3 into the inner cap 2 through the inlet 11 of the pipe body 1, and the charge density is 0.8g / cm 3 , wherein the low-energy explosive 3 includes passivated PETN0.10g, passivated RDX0.09g, KNO30.06g;

[0074] 3) Put the five-core extension body 4 into the inside of the pipe body 1 through the inlet 11 of the pipe body 1, the bottom of the extension bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com