Vacuum explosion-proof equipment for explosive material Hopkinson bar test

A technology of Hopkinson rods and explosion-proof devices, applied in the direction of material explosion, which can solve the problems of burning, destructive power enhancement, guide rod impact, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, it should be noted that the present invention is not limited to following specific embodiment, all equivalent transformations carried out on the basis of the technical solution of the present invention are all within the scope of protection of the present invention.

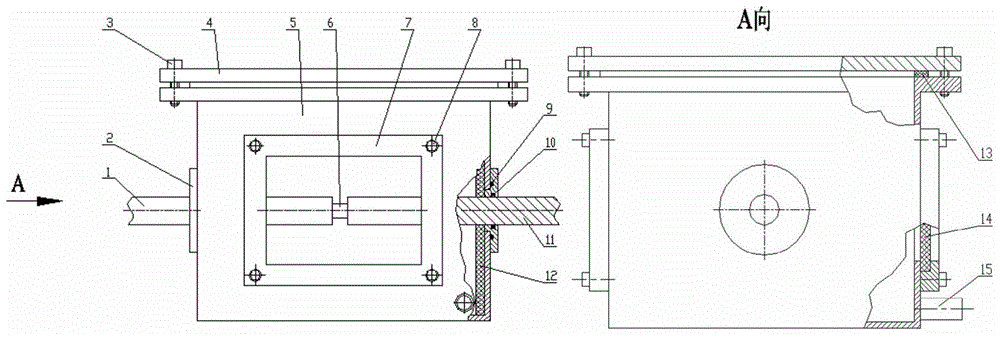

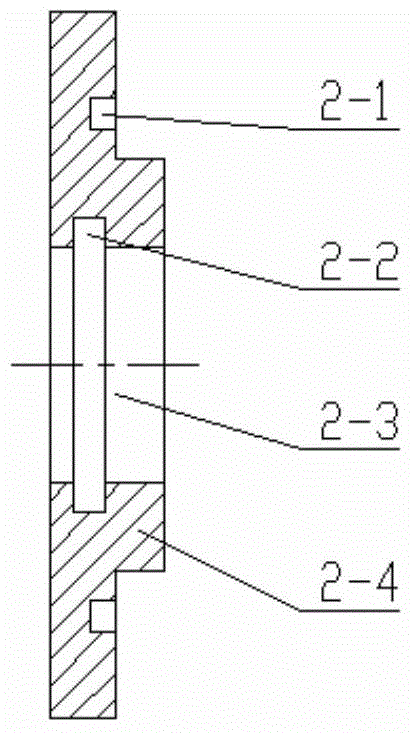

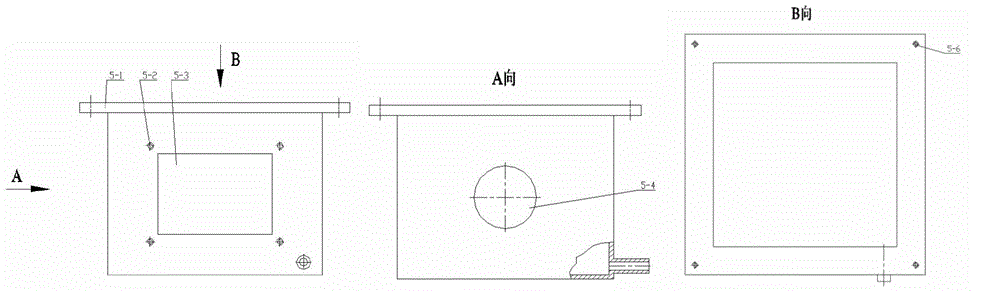

[0017] Such as Figure 1-Figure 5 As shown, this embodiment provides a vacuum explosion-proof device for the Hopkinson rod test of explosive materials, including a transmission rod 1, hexagon socket screws [3, 8], a cover plate 4, an explosion-proof box 5, an explosive sample 6, The incident rod 11 is characterized in that it also includes a rod sleeve 2, a fixed frame 7, a rod sleeve seal ring 9, a rod seal ring 10, a buffer device 12, a cover plate gasket 13, a window cover plate 14, and an air extraction pipe 15. The explosion-proof box 5 is a steel box body. The box body is welded by four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com