A potentiometer automatic thread cutting packaging machine

A potentiometer and packaging machine technology, applied in the manufacture of resistors, circuits, and resistors, can solve the problems of low efficiency, high labor costs, and inability to adapt to modern production, and achieve the effect of reducing costs and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

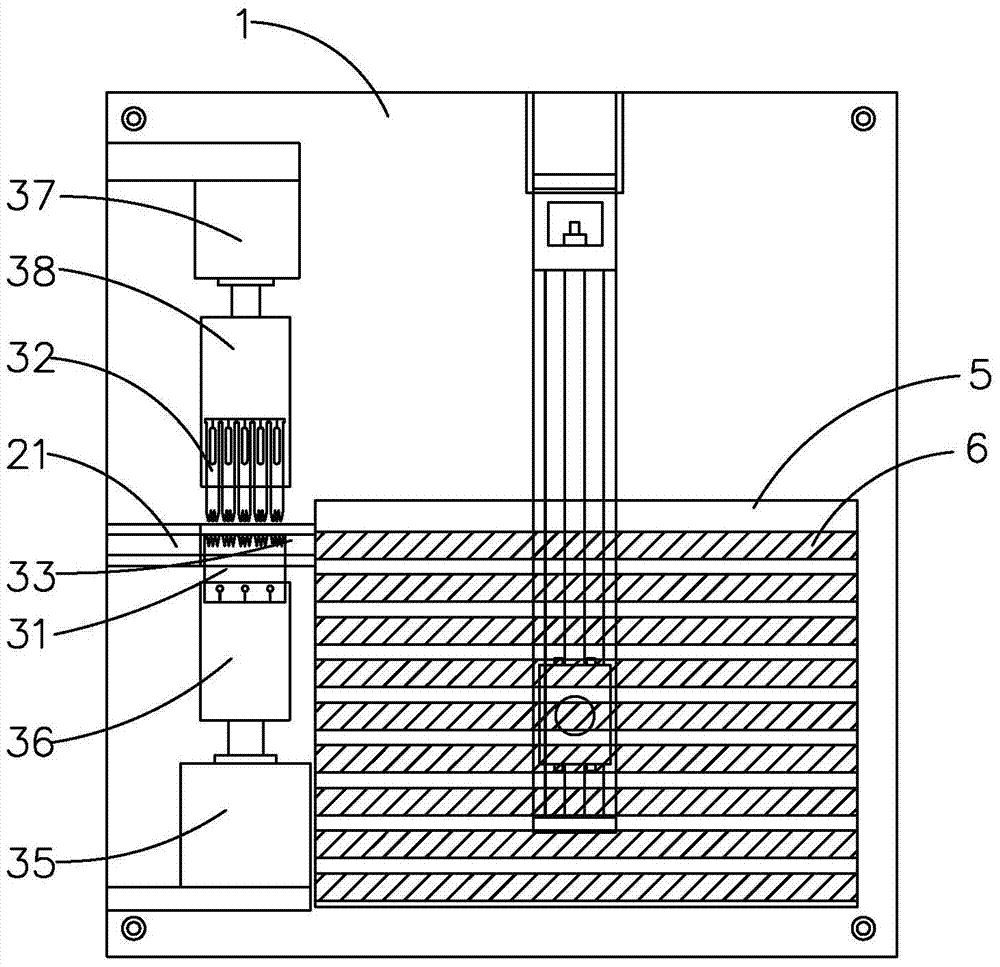

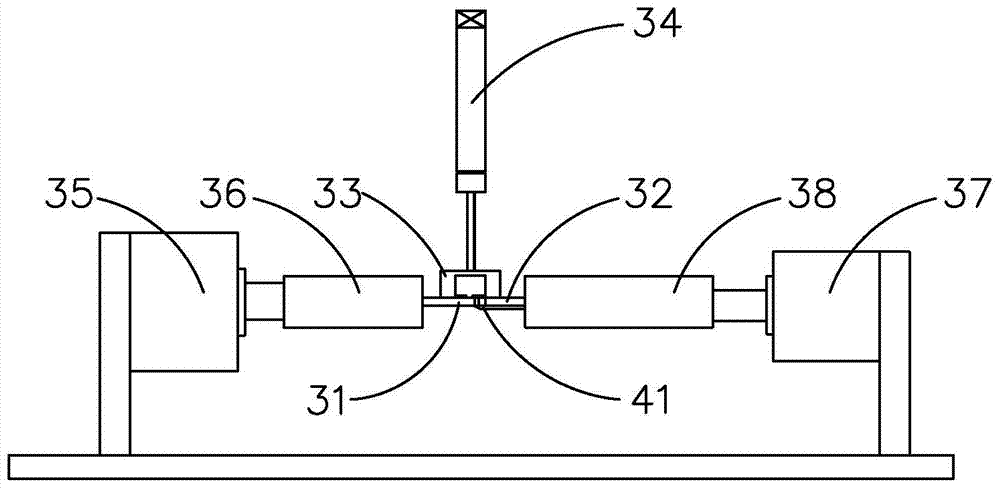

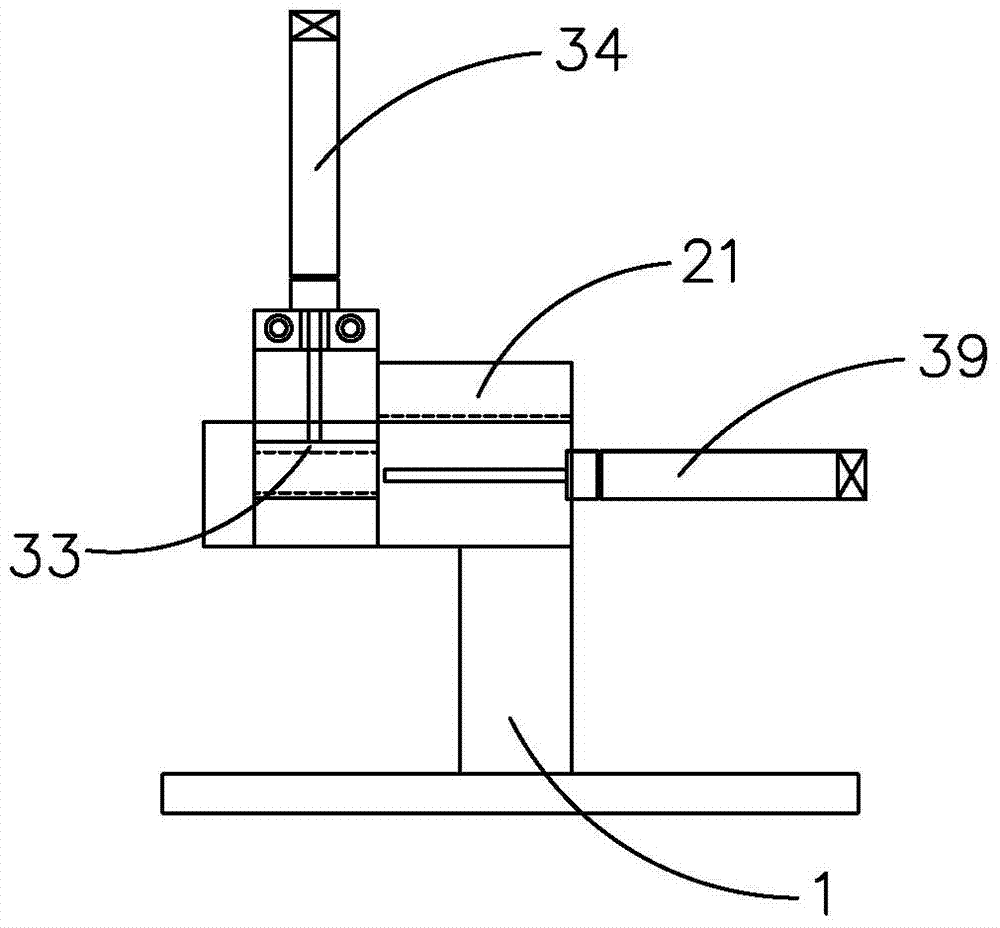

[0022] Such as Figure 1 to Figure 5 As shown, the potentiometer automatic thread cutting packaging machine of the present invention includes a frame 1, a feeding assembly, a detection assembly, a straightening assembly, a thread cutting assembly and a packaging assembly, and the frame 1 is mainly used to install each assembly of the packaging machine to the corresponding Position, these components include but not limited to: feed assembly, detection assembly, alignment assembly, tangent assembly and package assembly; feed assembly is used for delivering potentiometer to alignment assembly, comprises feed channel 21, feed channel 21 inlets One end of the vibrating plate is connected to the vibrating plate. The vibrating plate belongs to the prior art and is an auxiliary feeding device. It automatically arranges the potentiometers in an orderly and or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com