a battery capacitor

A capacitor and battery technology, which is applied in the field of battery capacitor structure and super capacitor, can solve the problems of battery short circuit, product application process limitation, battery capacitor impedance, etc., so as to improve the performance of shockproof and drop resistance, reduce the limitation of application range, Reduced effect of stent placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

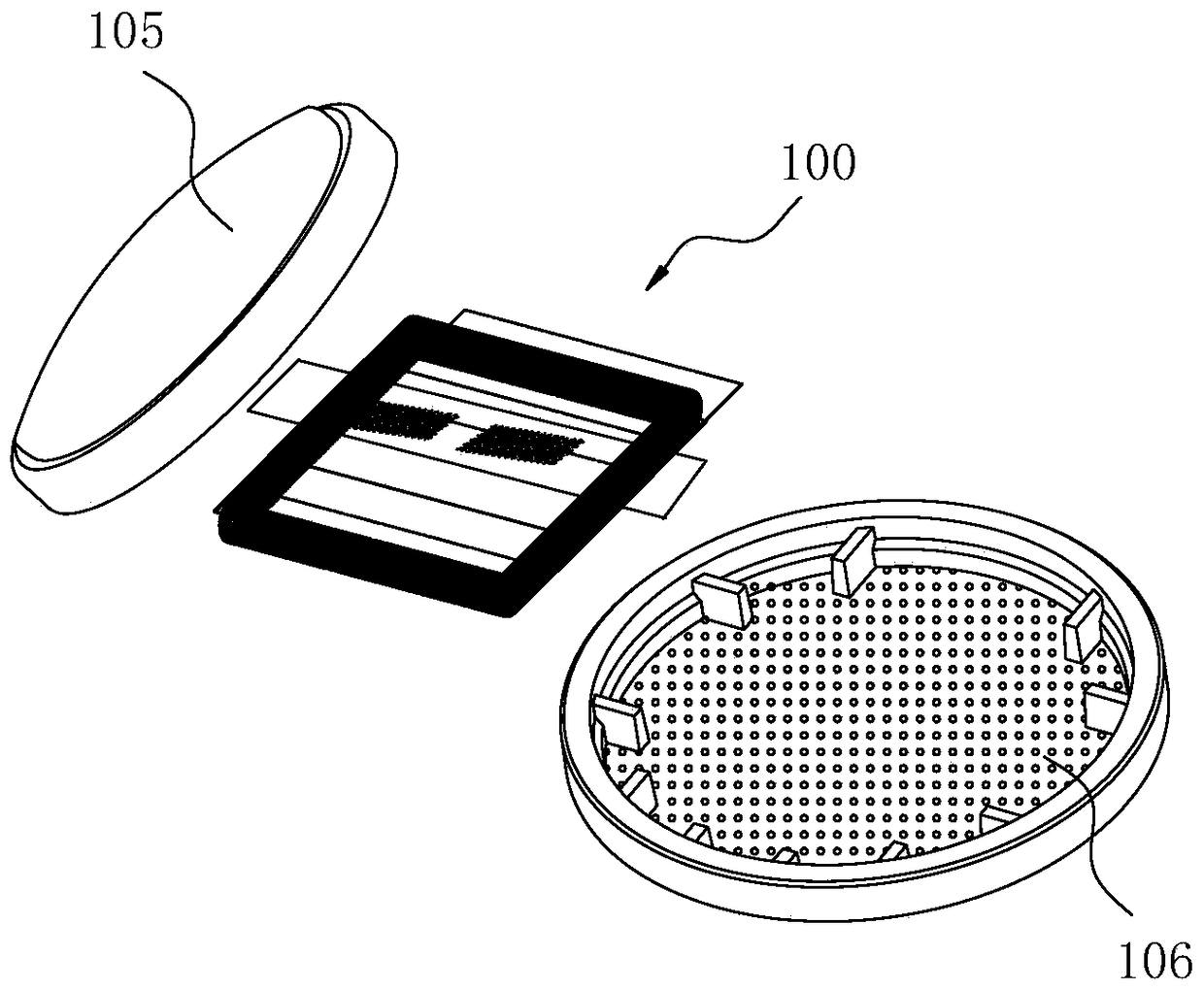

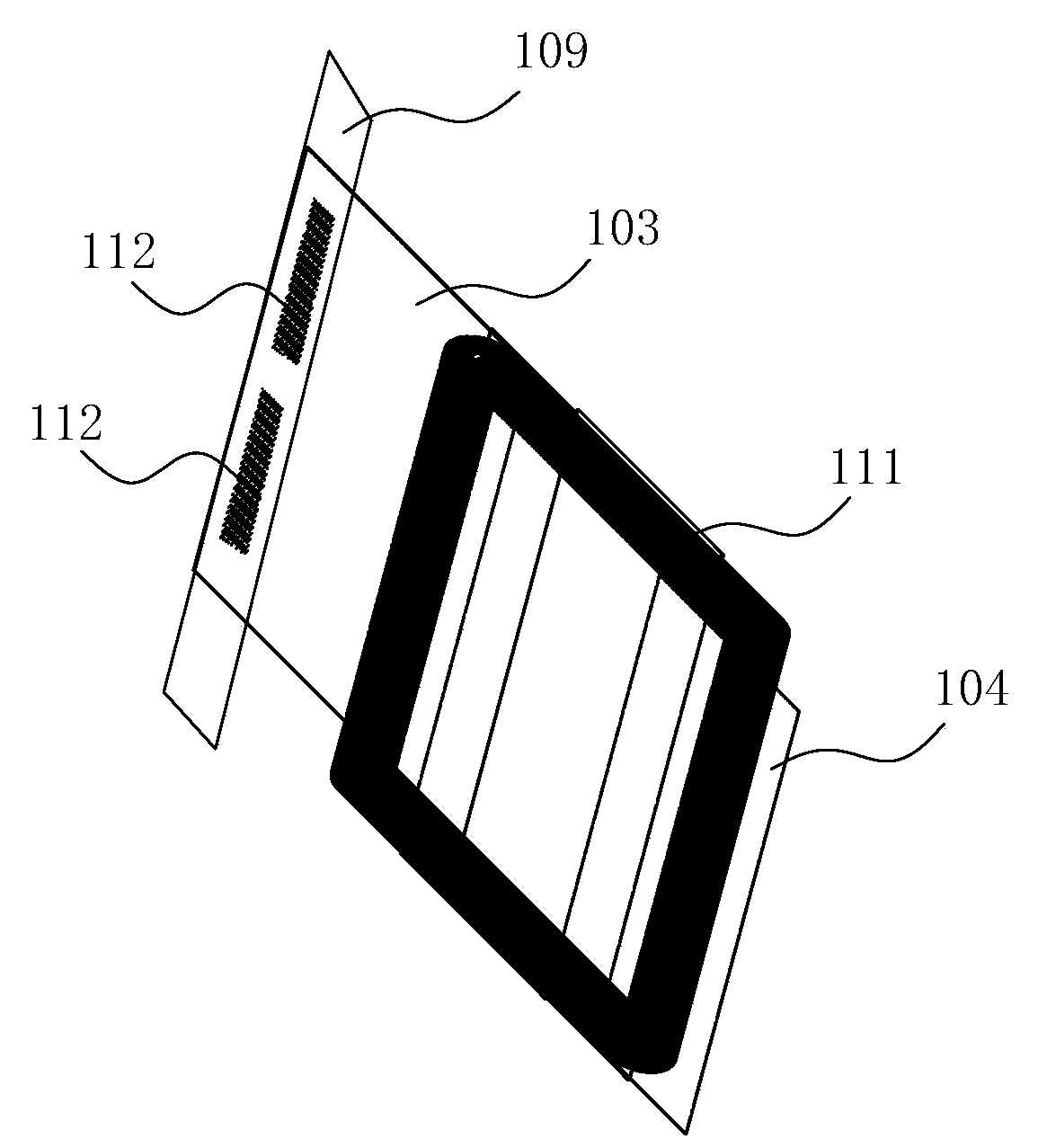

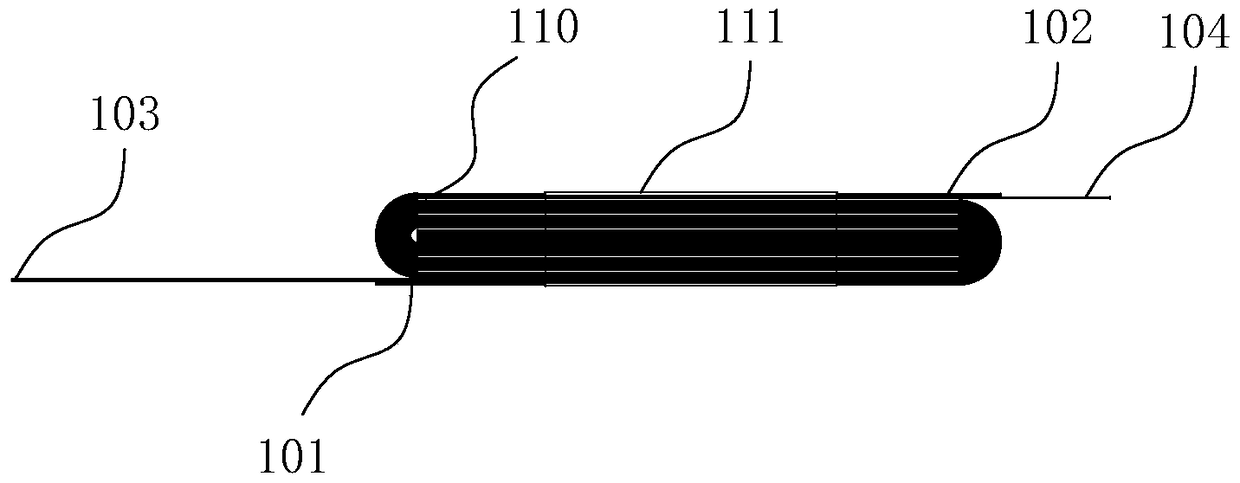

[0046] Such as Figures 1 to 6 As shown, a battery capacitor disclosed in the present invention includes a battery capacitor casing composed of a positive electrode casing 105 and a negative electrode casing 106 connected to each other; a battery cell 100 is arranged between the positive electrode casing 105 and the negative electrode casing 106; the battery cell 100 includes a positive electrode sheet 101. Negative electrode sheet 102 and ion-permeable microporous membrane 110; positive electrode sheet 101 is formed by coating a positive electrode material with a current collector, and is provided with an extended conductor 103 for the positive electrode sheet; negative electrode sheet 102 is formed by coating a negative electrode material with a current collector , and is provided with a negative electrode sheet extension conductor 104; an ion-permeable microporous membrane 110 is located between the positive electrode sheet 101 and the negative electrode sheet 102 for isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com