Preparation method of sulfur mesoporous silica composite material encapsulated by nano-valve

A technology of mesoporous silica and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor cycle stability, structural collapse, and loss of active materials of lithium-sulfur batteries, and achieve improved Coulombic efficiency and cycle stability Sex, reduce the shuttle effect, reduce the effect of structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

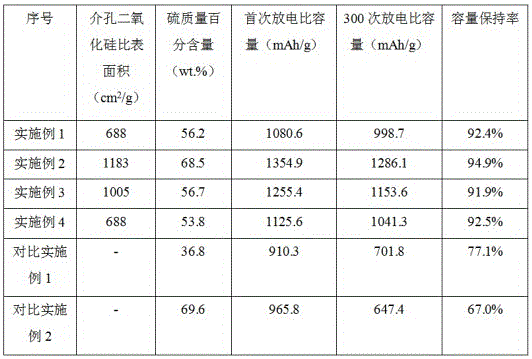

Examples

Embodiment 1

[0021] Synthesis of mesoporous silica: Dissolve 1 g of cetyltrimethylammonium bromide (CTAB) and 4 ml of concentrated ammonia water in 40 ml of deionized water, stir magnetically at 30 °C for 1 h to dissolve completely, and then Add 2.5 ml tetraethyl orthosilicate (TEOS) dropwise to the solution, continue stirring at room temperature for 24 hours to crystallize, and filter, wash, and dry the resulting precipitate. The dried product was extracted three times in an ethanol solution at 60°C to remove the template agent, filtered, washed, and dried to obtain the mesoporous silica material MCM-41.

[0022] Surface modification of mesoporous silica: add 100 mg of MCM-41 mesoporous material into 10 mL of anhydrous toluene, stir it with magnetic force to make it evenly dispersed, and then quickly add 0.1 mmol of organosilane molecule N-phenylamine formazan Triethoxysilane (PhAMTES) was heated under reflux at 80 °C for 24 h, filtered, washed with toluene and methanol three times to tho...

Embodiment 2

[0026] Synthesis of hollow spherical mesoporous silica: Take 0.5g of polyvinylpyrrolidone (PVP-10) and dissolve it in 100 mL of absolute ethanol / deionized aqueous solution with a volume ratio of 20 / 80, and magnetically stir for 1 hour to completely dissolve it ; Add 1.17g of dodecylamine (DDA) into 5 mL of absolute ethanol, mix the two solutions, continue to stir for 1h, then add 5ml of tetraethyl orthosilicate (TEOS) dropwise to the mixed solution, and continue to stir for 24h , filtered, washed, and dried, and the dried product was extracted three times in ethanol solution at 60 °C to remove the template agent, filtered, washed, and dried to obtain hollow spherical mesoporous silica with a pore size of 4 nm.

[0027] The surface treatment of the mesoporous silica, the loading of sulfur and the synthesis steps of the nano-valve are the same as in Example 1. The difference is that during the sulfur loading process, the mass ratio of mesoporous silica to sulfur is 1:3.

Embodiment 3

[0029]Surface modification of mesoporous silica: Add 100 mg of commercial SBA-15 mesoporous material into 10 mL of anhydrous toluene, stir it with magnetic force to make it evenly dispersed, and then quickly add 0.1 mmol of organosilane molecule N-phenylamine Propyltrimethoxysilane (PhAMTMS) was heated under reflux at 80 °C for 24 h, filtered, washed with toluene and methanol three times to thoroughly wash off the organic silane chain molecules adsorbed on the surface, and finally vacuum-dried to obtain the surface Modified SBA-15 mesoporous material with a pore size of 10nm.

[0030] The loading of sulfur and the synthesis of nano-valve are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com