Thread guide unit, motion damper for a thread guide unit, and method for producing the motion damper

A technology of buffers and wire guides, which is applied in the directions of transportation and packaging, friction dampers, and delivery of filamentous materials, etc. It can solve the problems of short maintenance or repair intervals of wire guide units and unfavorable service life of traction mechanisms, etc., to achieve Effects of improved service life, simple manufacture, and increased surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

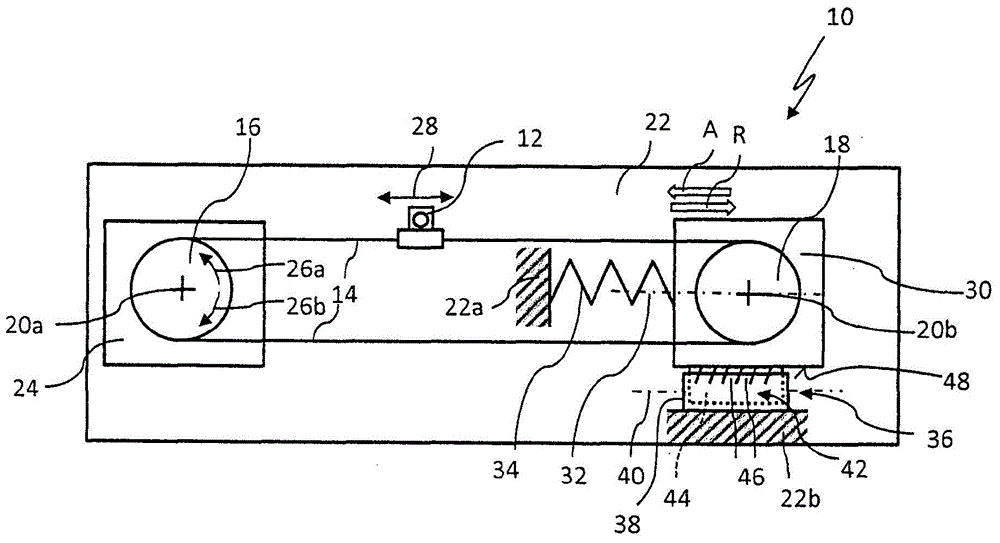

[0034] figure 1 The thread guide unit 10 is shown with a thread guide 12 which is fastened to a cable-like pulling mechanism 14 . The traction element 14 surrounds a deflection roller 16 and a tensioning roller 18 , which are mounted rotatably about an axis of rotation 20 a , 20 b in each case on a plate-shaped support 22 of the thread guide unit 10 . As shown in the figure, the traction means 14 can be designed in the form of a ring. The deflection roller 16 can be driven about its axis of rotation 20 a in opposite directions of rotation 26 a , 26 b by a drive motor 24 and thus serves as a drive roller for the traction mechanism 14 . The yarn guide 12 can thus be reciprocated by the pulling mechanism 14 in rapid sequence in the reciprocating direction indicated by the double arrow 28, for example to wind the yarn guided on the yarn guide 12 onto a bobbin (not shown) .

[0035] Such as figure 1As shown, the tensioning roller 18 is mounted displaceably relative to the carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com