A remote operation control method based on knob type force feedback hand controller and mechanical arm

A technology of remote operation control and robotic arm, applied in the field of remote operation, can solve the problems of low precision, inconvenient operation, cumbersome hand controller, etc., and achieve the effect of reducing hardware cost, prolonging service life, and easy and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

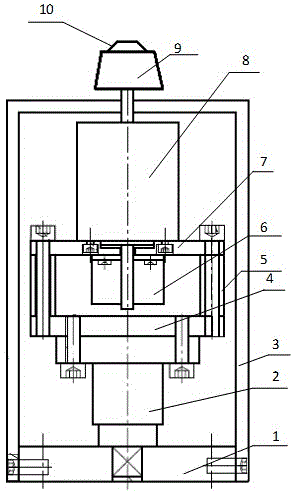

[0035] Such as figure 1 As shown, a knob-based force feedback hand controller includes a base plate 1, a torque sensor 2, a housing 3, a sensor flange 4, a distance sleeve 5, an encoder 6, a motor seat plate 7, a motor 8, and a fine The switch knob 9 of the switch 10, the housing 3 and the bottom plate 1 are fixedly connected to form a closed space; the distance sleeve 5 is fixedly connected between the motor seat plate 7 and the sensor flange 4, and the motor seat plate 7 and the sensor flange 4 are formed. In the installation space, the torque sensor 2 is fixedly connected to the bottom surface of the sensor flange 4, the encoder 6 is located in the installation space, and the housing of the encoder 6 is fixedly connected to the bottom surface of the motor base plate 7, and the motor 8 is fixedly connected to the motor base plate 7 and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com