Rigid suspension system device for overhead contact line

A suspension system and catenary technology, which is applied in the direction of overhead lines, etc., can solve the problems of unsatisfactory busbar sliding smoothness and unreasonable life matching of rigid suspension systems, so as to prevent or reduce sticking phenomenon, reasonable service life of the system, The effect of ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

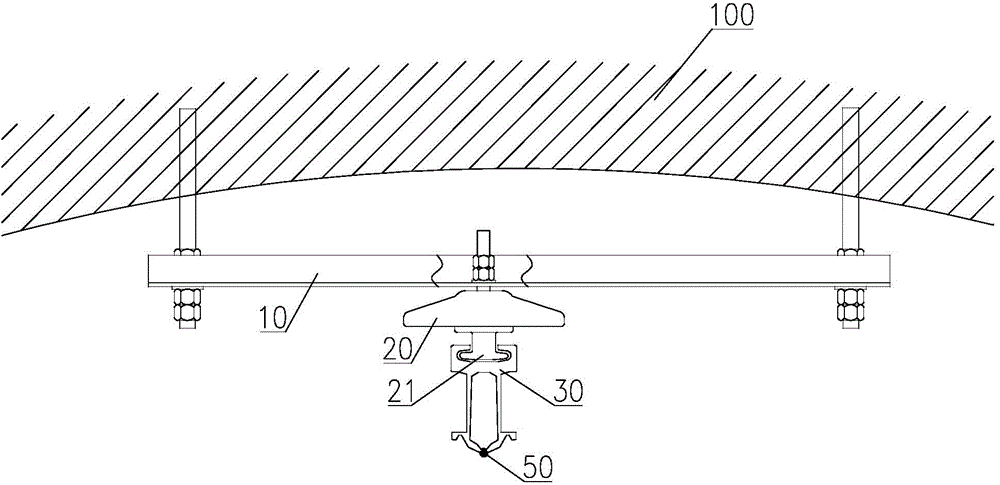

[0027] See figure 1 and figure 2 As shown, the overhead catenary rigid suspension system device includes: a suspension device 10 fixed on the tunnel top 100, an insulator 20 fixed on the suspension device 10, a bus bar 30 suspended on the insulator 20, and The lower part of the bus bar 30 is fixed with a contact wire 50 . Of course, the tunnel top 100 can also be a frame.

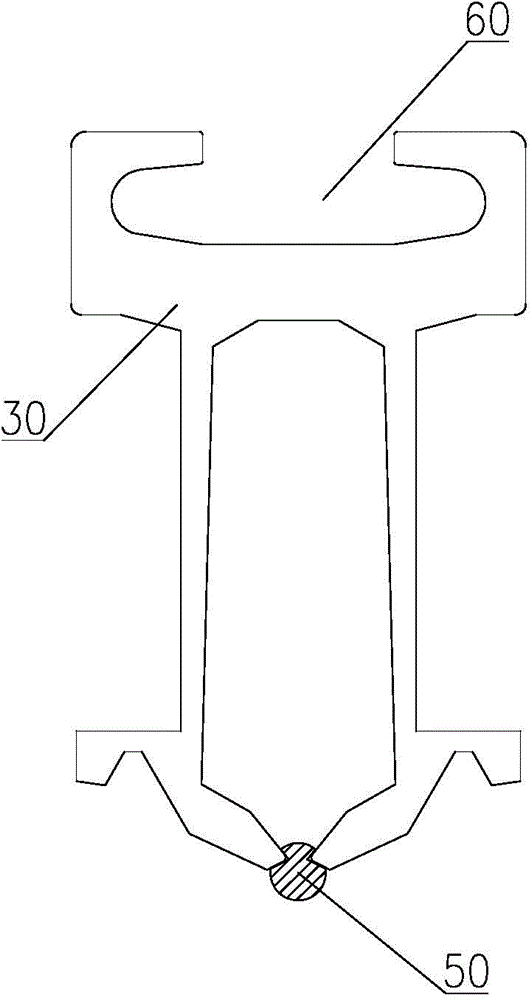

[0028] Furthermore, the upper part of the insulator 20 is fixed on the suspension device 10 by M16 and other screws. The lower part of the insulator 20 is provided with a club head type connector 21 . The so-called club head type means that the connecting head 21 is approximately oblate. At the same time, the upper part of the bus bar 30 is provided with a slot 60 , the cross section of which is semi-enclosed with the opening facing upwards, and the connector 21 is stuck in the slot 60 after entering from one end of the slot 60 . Of course, the slot 60 extends along the longitudinal direction of the b...

Embodiment 2

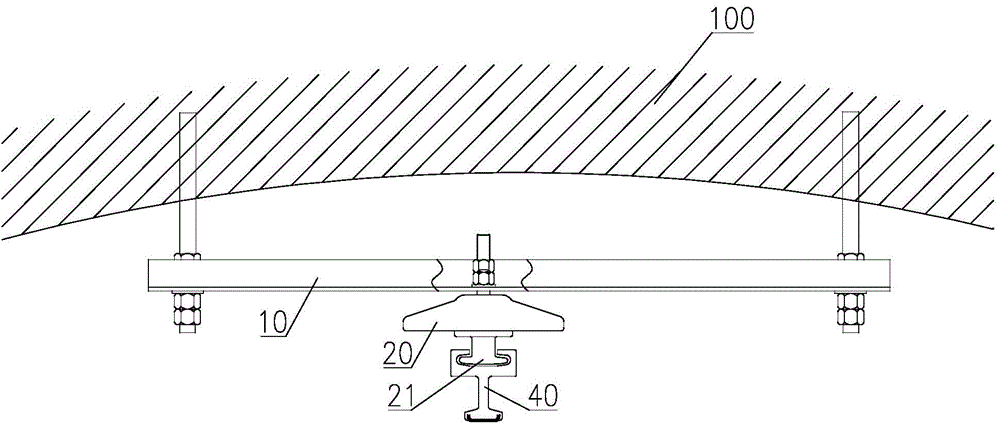

[0032] See image 3 and Figure 4 As shown, the difference from Embodiment 1 is only that: the bus bar 30 is replaced by a contact rail 40, the slot 60 is located on the upper part of the contact rail 40, and the contact wire 50 is fixed to the contact rail by composite or welding process The stainless steel belt 41 of 40 lower parts or aluminum rail replace. In this way, the pantograph-catenary can transition smoothly, receive current stably, and further extend the maintenance cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com