Fully-automatic battery label sleeving equipment

A fully automatic, battery-powered technology, applied in the direction of conveyor objects, packaging/bundling items, packaging, etc., can solve the problems that affect the overall efficiency of sleeve labels, low degree of automation, poor product consistency, etc., to shorten heat shrink time and save Artificial, uniform shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

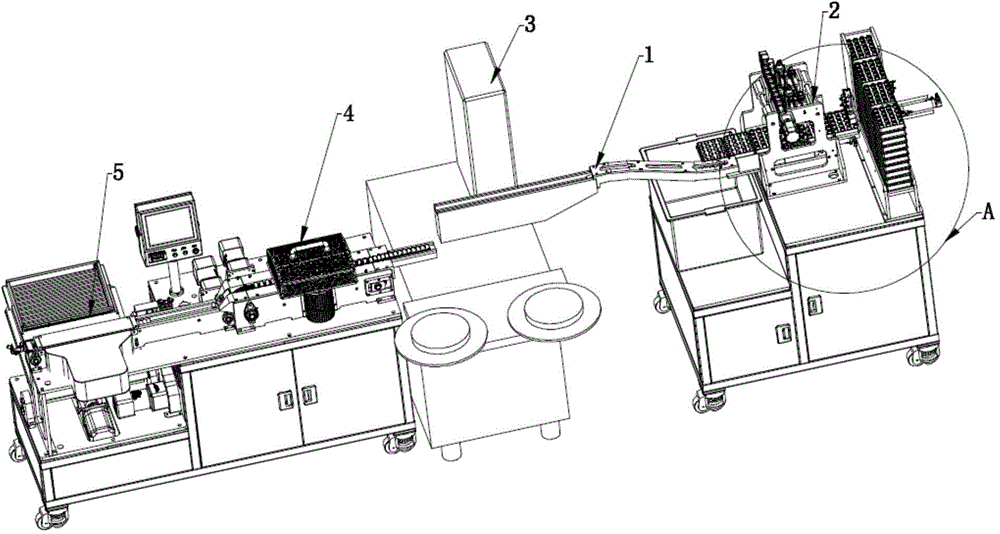

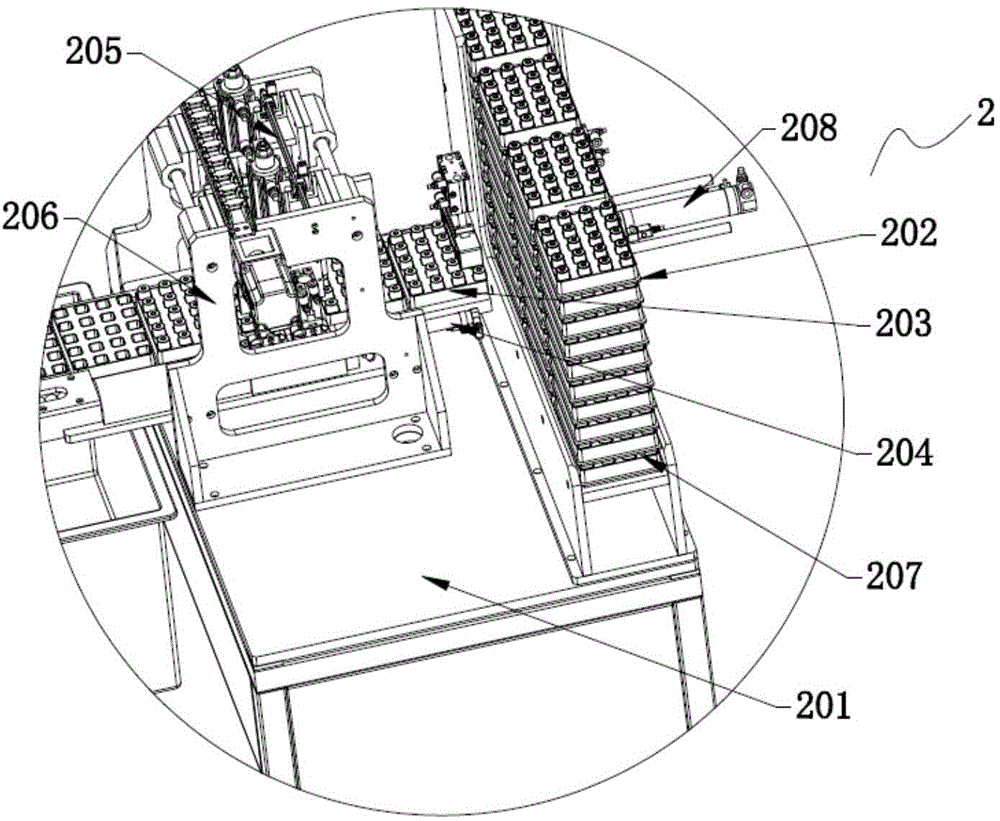

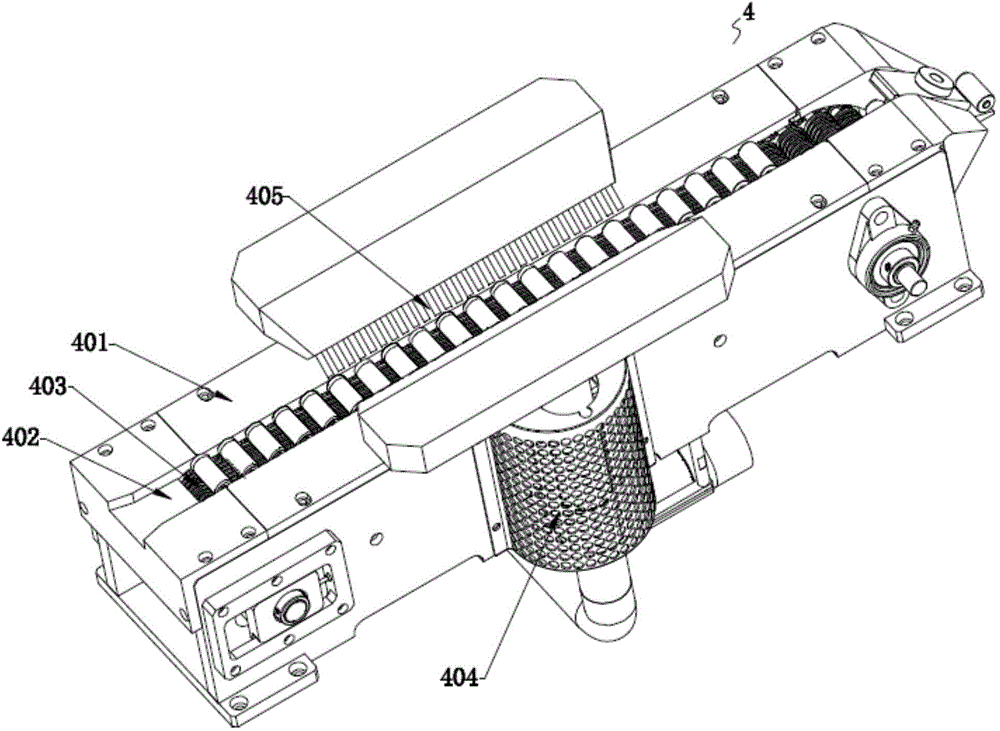

[0023] Such as figure 1 As shown, this embodiment provides a fully automatic battery labeling device, including a conveying mechanism 1 for conveying batteries, along which conveying mechanism 1 is provided in sequence: an automatic feeding mechanism 2 that puts batteries into conveying mechanism 1 in sequence ; the sleeve labeling machine 3 used for the battery sleeve sleeve label film driven by the conveying mechanism 1; the hot air shrinkage mechanism 4 used to heat the battery covered with the sleeve label film so that the sleeve label film shrinks and fixes the battery; and the sleeve label The battery after shrinking and fixing the film is taken out from the conveying mechanism and collected in the automatic unloading and packaging mechanism 5 of the receiving and packaging tray.

[0024] In this embodiment, the conveying mechanism 1 can be configured as a conveyor belt provided with fixed conveying rails, so that the batteries run along the same direction of the fixed c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap