Flexible circuit board feeding mechanism and preloading additional nozzle

A flexible circuit board, pre-pressing technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient replacement, adverse production efficiency, and affecting the stability of components, so as to reduce the time of line change, facilitate industrial application, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

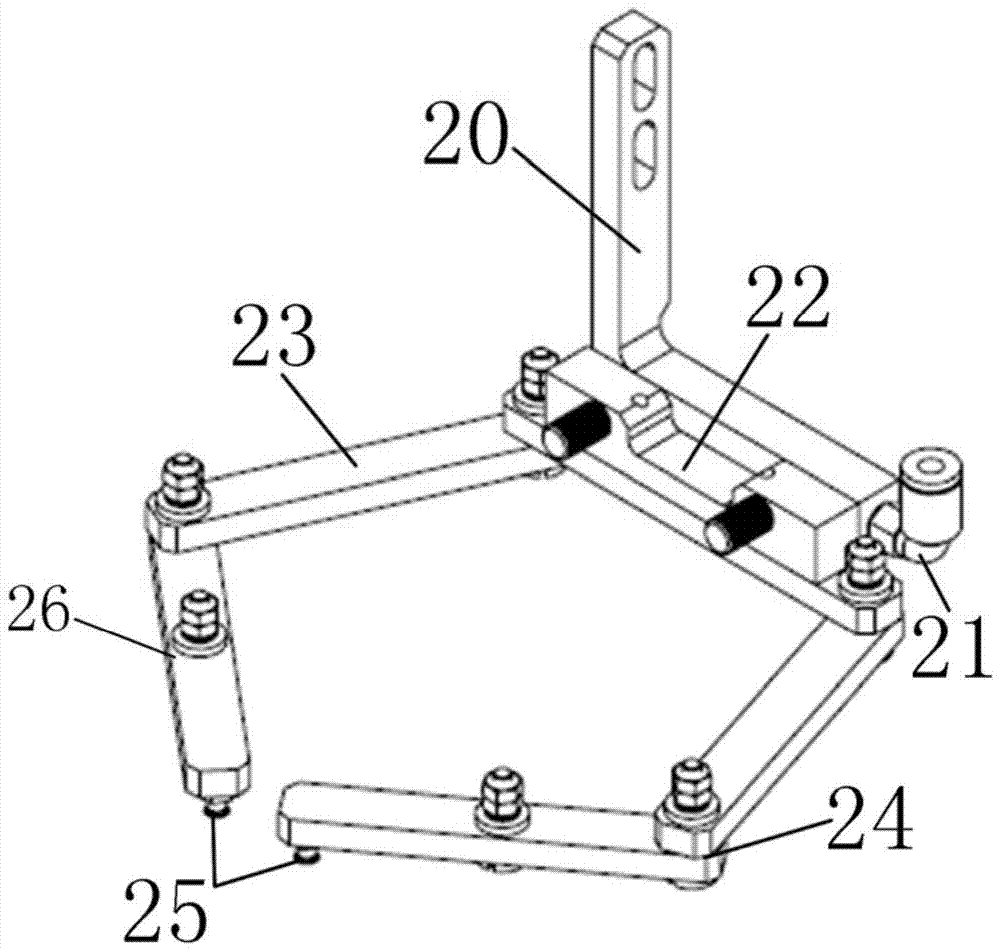

[0028] refer to image 3 , is a structural schematic diagram of the improved pre-pressing additional suction nozzle proposed in the present invention, including an L-shaped fixed end 20, a vacuum inlet pipe 21, a first vacuum air pipe 22, a second vacuum air pipe 23, a joint 24, a vacuum suction nozzle 25, and a vacuum suction pipe. Mouth control switch 26.

[0029] The additional preloading nozzle includes an L-shaped fixed end 20; one end of the L-shaped fixed end 20 is fixedly connected to the preloading head, and a vacuum inlet pipe 21 is provided at the end face of the other end;

[0030] The above-mentioned pre-pressing additional suction nozzle also includes that the outer surface of the L-shaped fixed end 20 is fixedly connected with the first vacuum air pipe 22 .

[0031] Both sides of the above-mentioned f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com