Crawler crane boom structure and crawler crane

A crawler crane and jib technology, applied in the field of crawler crane jib structure, can solve the problems of increased working cost, high use cost and high use cost, achieve precise control of working range, precise control of hoisting load, and reduce use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

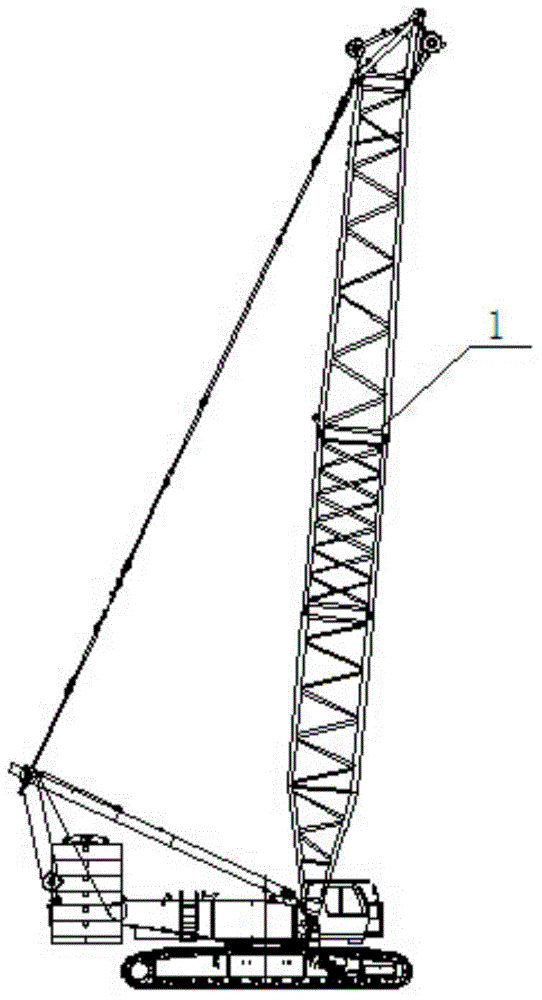

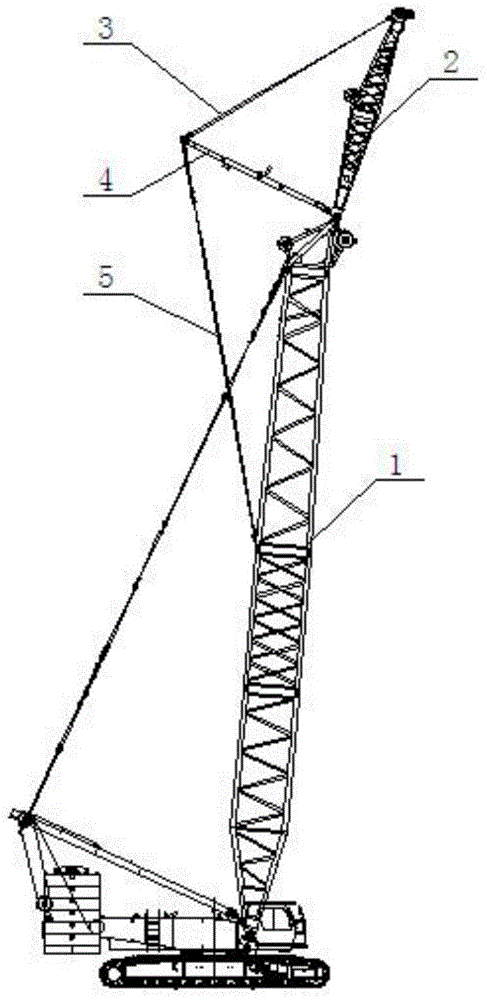

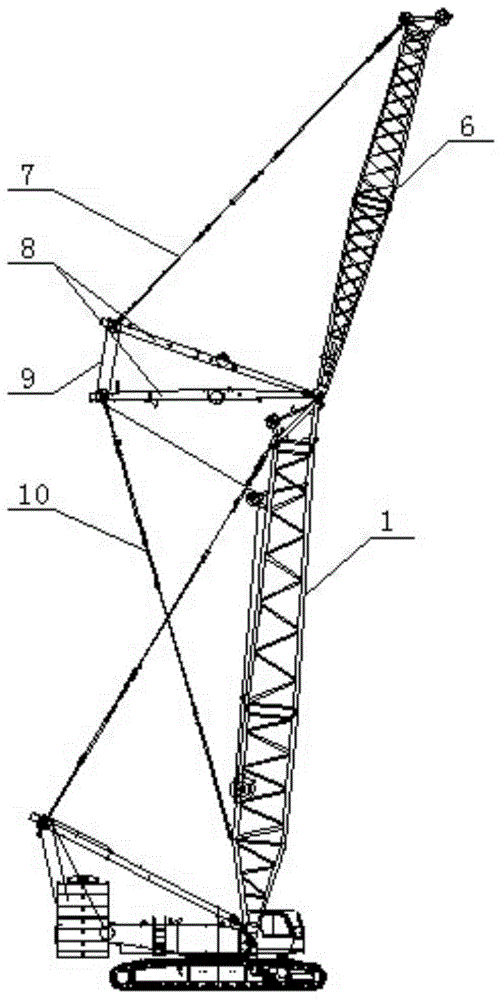

[0041] like Figure 4 to Figure 9 As shown, the boom structure of the crawler crane includes a fixed jib front pull plate 3 connecting the main arm 1 and the fixed jib 2, a single bracket 4 and a fixed jib rear pull plate 5;

[0042] The front pull plate 3 of the fixed jib and / or the rear pull plate 5 of the fixed jib are connected to the single bracket 4 through a luffing pulley block 11;

[0043] A guide pulley 12 and a luffing winch mechanism 13 are installed on the main arm 1;

[0044] The luffing hoisting mechanism 13 is connected to the guide pulley 12 and the luffing pulley block 11 through a wire rope.

[0045] Through the structure of the single bracket 4 and the correspondingly added luffing pulley block 11, the structural forms of the single bracket fixed jib and the double bracket tower jib in the prior art are replaced, and it is the front and rear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com