Coding mechanism and key for clutch type lock

A clutch type and key technology, applied in the field of keys and coding mechanisms, can solve the problems of small amount of keys in the lock cylinder, high key mutual opening rate, complex structure of the lock cylinder, etc., and achieves low manufacturing cost, strong safety, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

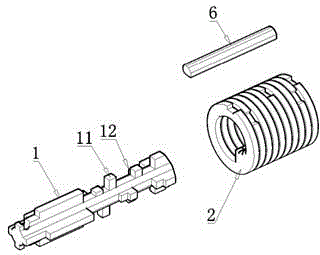

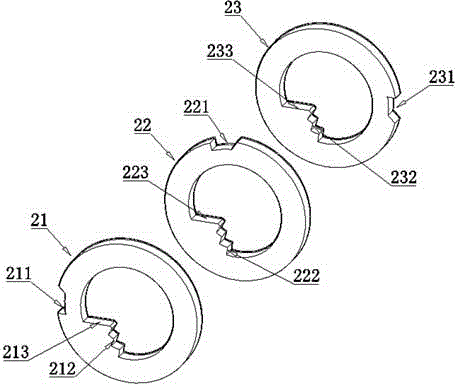

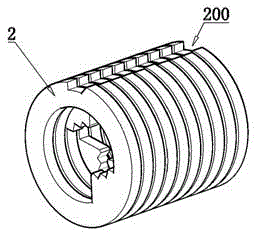

[0034] Such as figure 1 Shown encoding mechanism, key 1 and clutch pin 6. The encoding mechanism includes a plurality of encoding slices 2, and its structure is as follows: figure 2 As shown, the encoding sheet 2 is in the shape of a circular ring, and a plurality of encoding sheets are divided into N types. The outer edge of the first type of encoding sheet 21 has a clutch groove 211 for the first type of encoding sheet, and the inner edge of the ring is provided with The bump that protrudes toward the center of the ring has a first-type coding piece tooth groove 212 on the bump; the second-type coding piece 22 has a second-type coding piece clutch groove 221 on the outer edge of the ring, and the inside of the ring The edge is provided with a protruding block protruding toward the center of the ring, and the second type coding piece tooth groove 222 is opened on the projection; the third type coding piece 23 has a third type coding piece clutch groove 231 on the outer edge...

Embodiment 2

[0054] Such as Figure 13 As shown, in this embodiment, the structure of the guide shaft 301 and the key 101 is different from that of Embodiment 1. The key 101 has only one rack, and there are four kinds of gear blocks with different heights on the rack, and the corresponding guide shaft 301 is also corresponding. There is only one bar-shaped hole, and each coding piece has 1 reset block and 4 layers of stepped tooth grooves. One of the tooth grooves of the same layer of coding pieces meshes with one of the tooth pieces, but on each coding piece, the clutch groove Groove is different from the same position of cog. Other structures are the same as in Embodiment 1.

Embodiment 3

[0056] Such as Figure 14 As shown, in the present embodiment, the structures of the coding piece and the key 102 are different from those of the first embodiment. Each coding piece has a reset block and a tooth groove, and there are 4 racks on the key 102, and each toothed rack has a There is only one kind of tooth block, but on each coding piece, the same position of the clutch groove and the tooth groove is different. Other structures are the same as in Embodiment 1.

[0057] In Embodiment 2 and Embodiment 3, since the racks on the key and the number of slots on the coding sheet are small, although this technical method can also be realized, the amount of coding information is small. Theoretically, the value of encoding information is infinite, but in the physical design, factors such as the size of the structure, the difference in encoding angle, and the performance of processing technology should be considered for comprehensive evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com