Steel-rope glass lifter for vehicle door

A technology for glass lifters and car doors, which is applied to door/window accessories, buildings, and operating mechanisms of wing sashes, etc., can solve the problems of complex production and assembly processes, high probability of assembly errors, and more failures of parts, etc. Incidence of failure modes, reduction of raw material consumption, effect of reduction of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

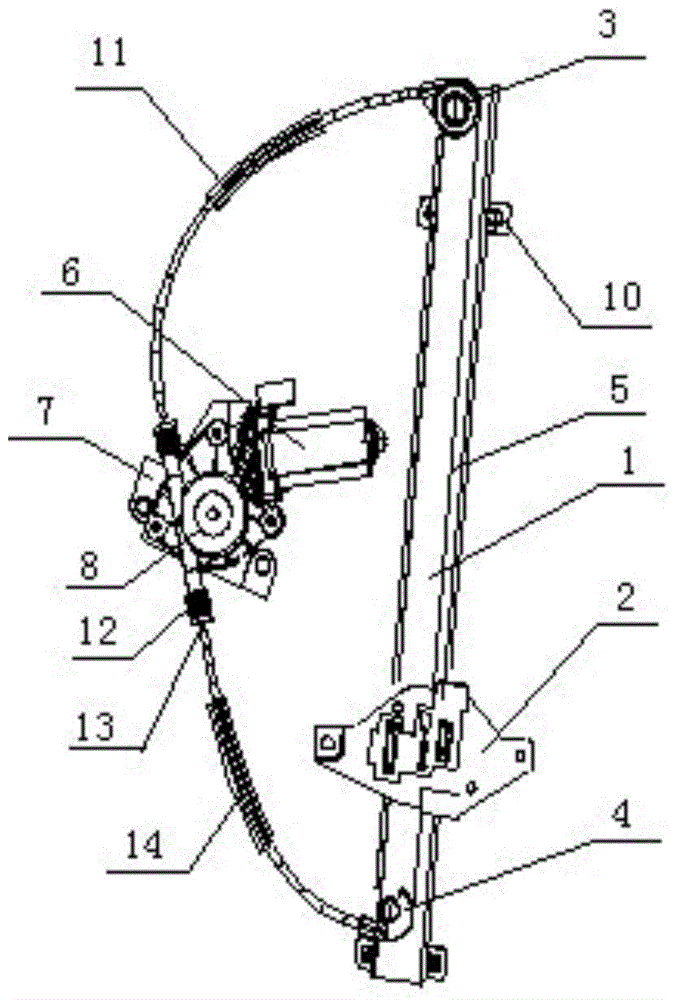

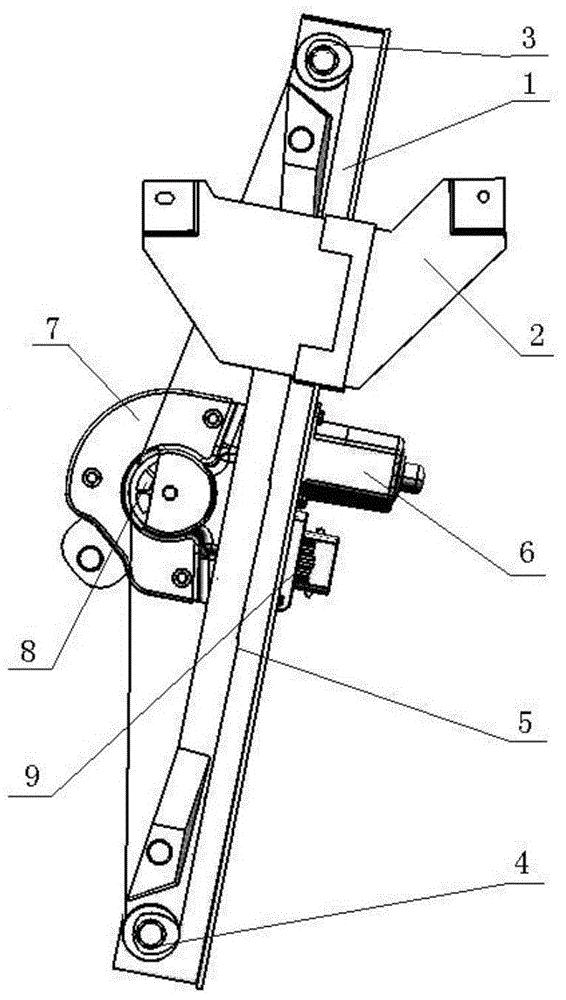

[0018] A further detailed description will be given below in conjunction with the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0019] Such as figure 2 The structure of the present invention is shown, which is a car door steel rope glass lifter, which includes a lifting slider 2 connected with the door glass, the lifting slider 2 is connected with a transmission steel rope 5, and the lifting slider Block 2 is placed on the lifting guide rail 1, and described transmission steel rope 5 walks around pulley 3, pulley 4 and is connected with rope drum 8, and motor 6 and rope drum 8 are fixed on the motor support 7.

[0020] In order to reduce the number of parts, reduce costs, and improve product reliability, the technical solution adopted by the present invention is:

[0021] In the car door steel rope glass lifter of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com