Manually integrated blowout preventer locking device

A locking device and blowout preventer technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of difficult operation, manual completion, high labor intensity, etc. The effect of blowout accident, firm and safe locking, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further disclose the technical solution of the present invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

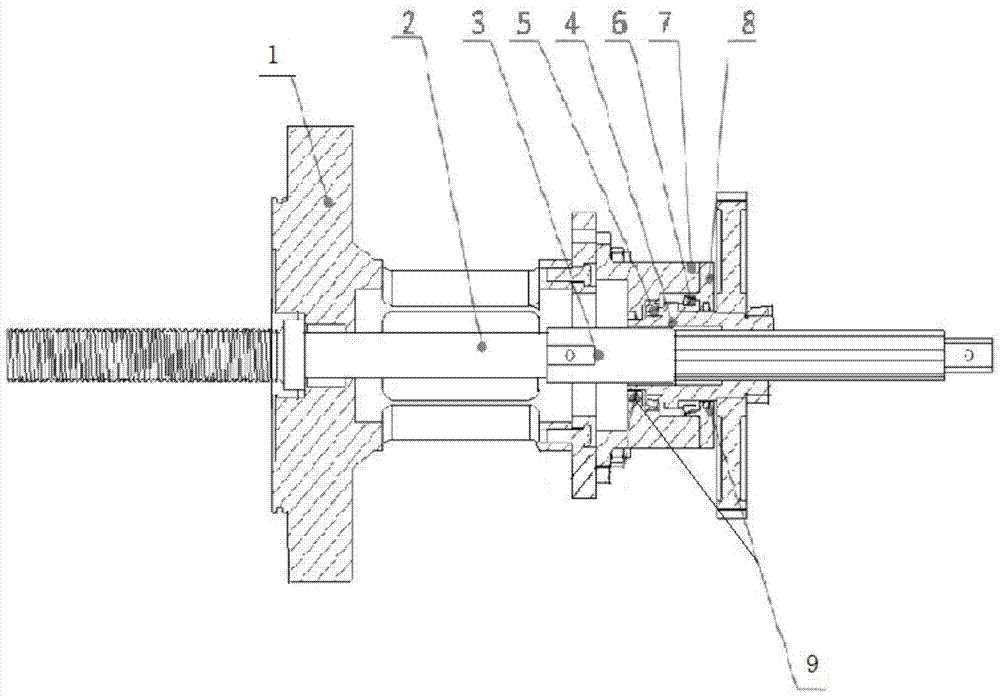

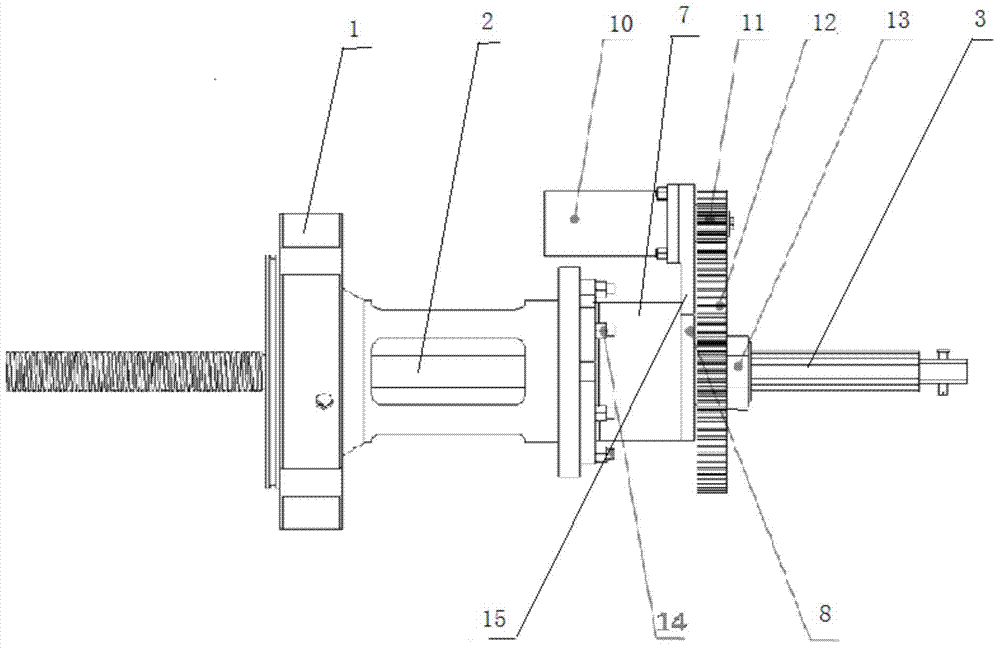

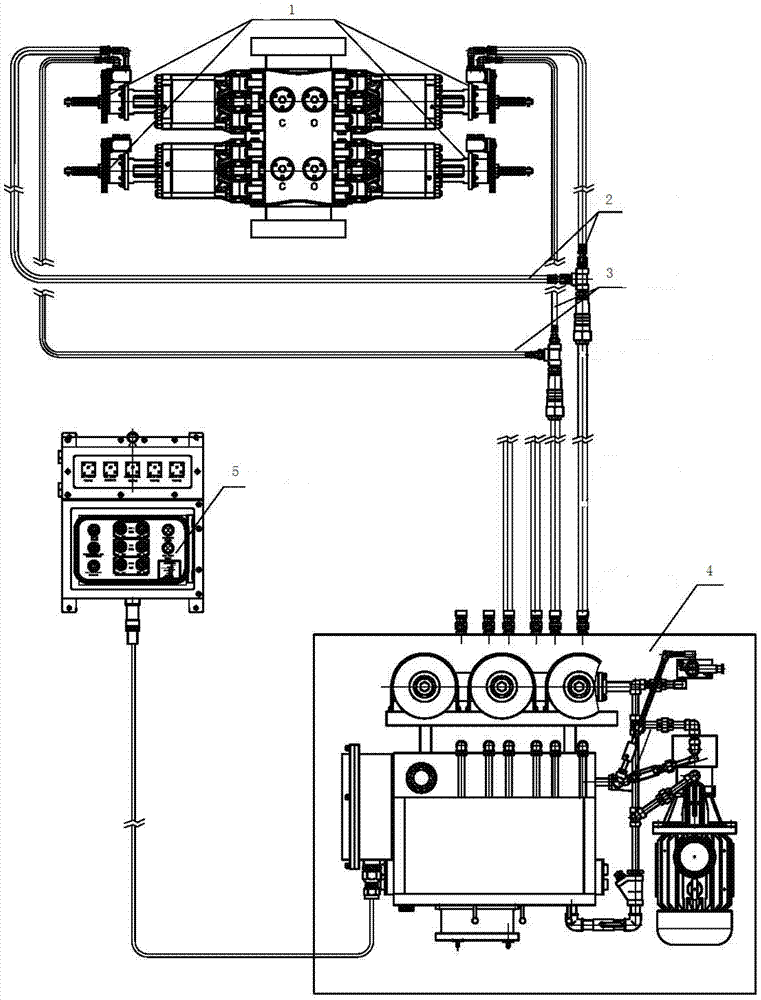

[0028] The invention includes a blowout preventer locking system, a blowout preventer locking control system, an automatic control system and a hydraulic pipeline, and is characterized in that: the blowout preventer locking system 1 includes a blowout preventer cylinder head 1-1, a locking rod 1 -2, bearing holder 1-7, front bearing 1-5, rear bearing 1-6, hydraulic motor 1-10, pinion gear 1-11, large gear 1-12, spline sleeve 1-4, spline shaft 1-3, the bearing fixing seat is connected with the blowout preventer cylinder head through the connecting plate, one end of the locking rod is connected with the ram screw of the blowout preventer through a pin, and the other end of the locking rod is connected with the spline shaft through a pin , the spline of the spline shaft meshes with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com