Shock wave compressor

A compressor and shock wave technology, applied in the field of compressors, can solve problems such as complex structure and reduced airflow speed, and achieve the effects of high gas compression efficiency, increased gas pressure, and improved compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

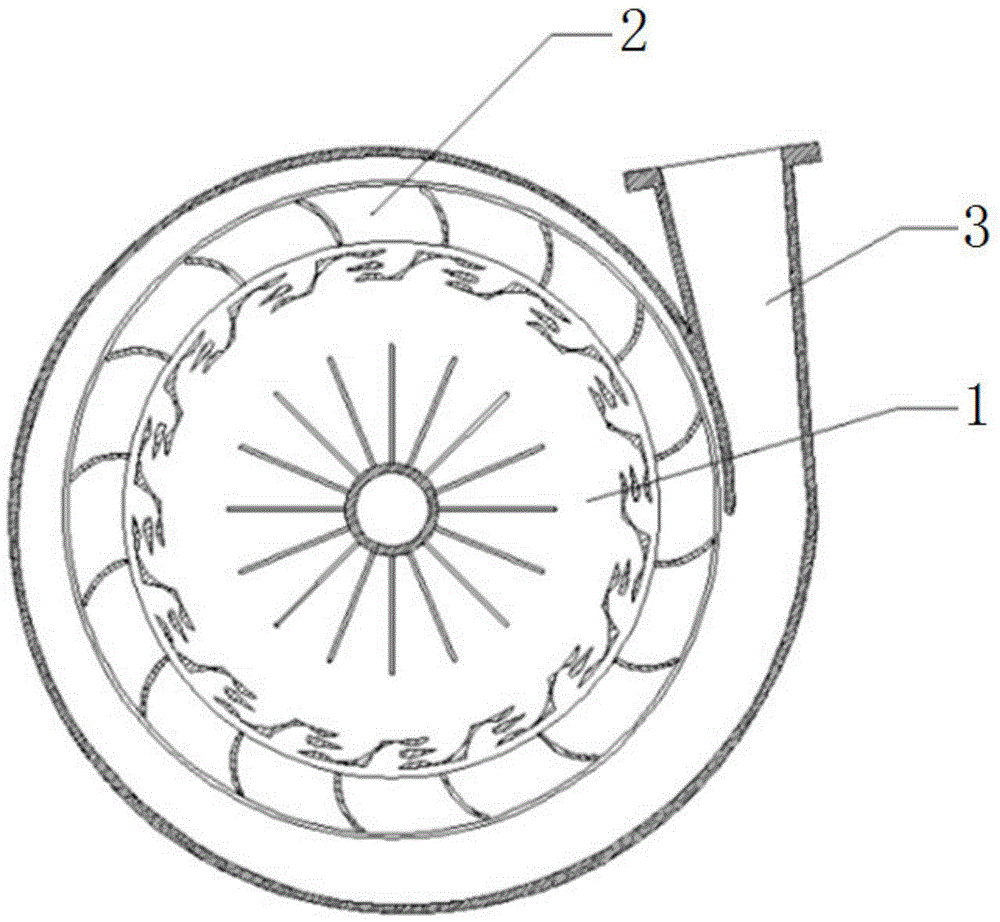

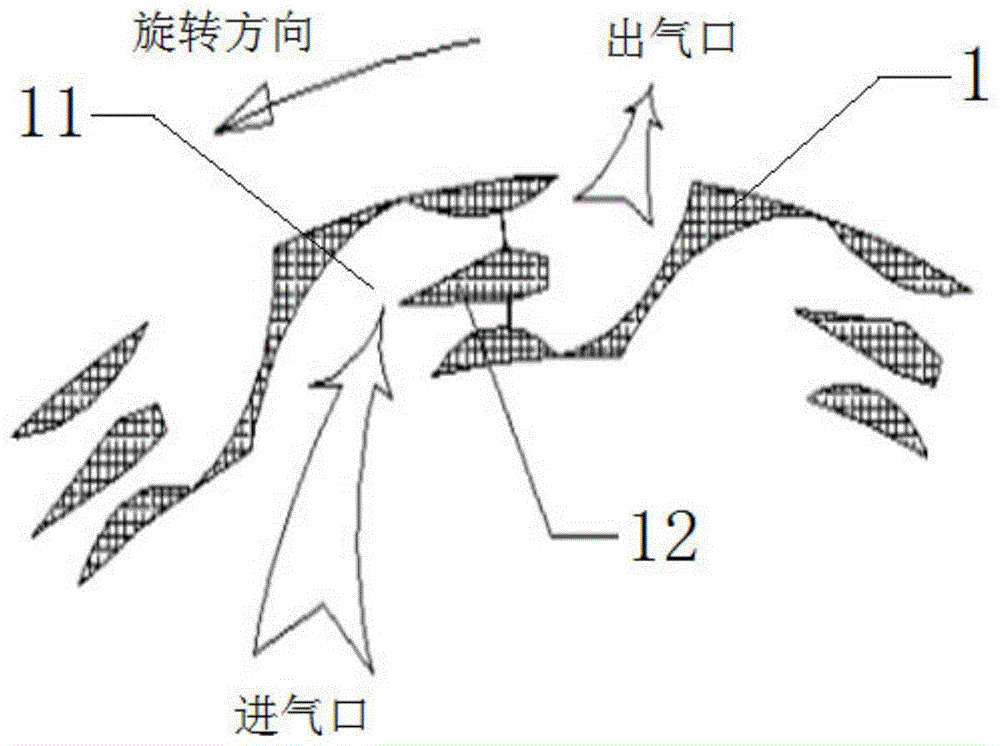

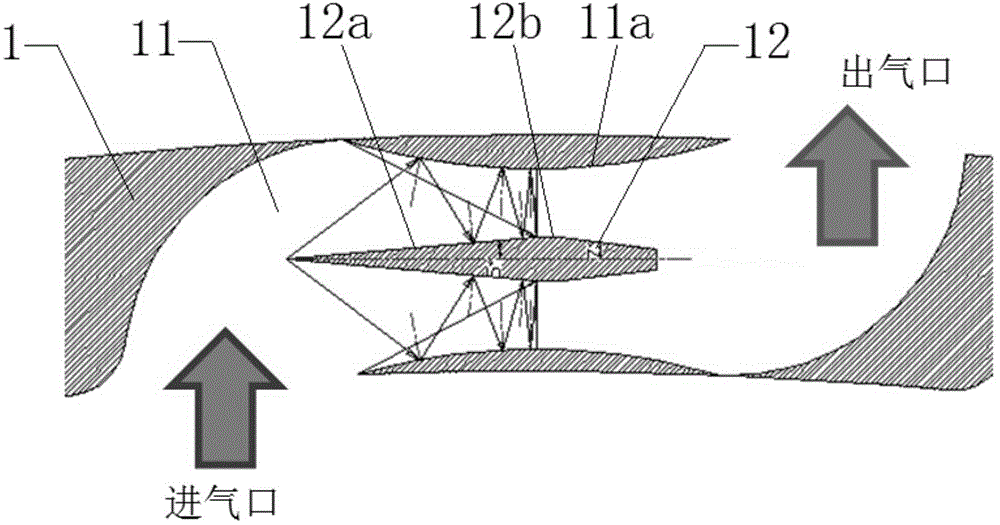

[0025] to combine figure 1 , figure 2 , image 3 with Figure 4 As shown, a shock wave compressor of this embodiment includes a rotary stamping rotor 1, a vane diffuser 2 and a booster volute 3, the rotary stamping rotor 1 is installed on a rotary shaft, and the rotary stamping rotor 1 and the vane diffuser The devices 2 are all arranged in the booster volute 3, and the edge of the rotary stamping rotor 1 is provided with several gas flow passages 11. In this embodiment, several gas flows 11 are evenly distributed on the edge of the rotary stamping rotor 1, so that the rotary stamping rotor 1 The center of gravity of the rotor 1 is located on the axis of the rotary stamping rotor 1, which makes the operation more stable; each gas channel 11 is provided with a shock wave induction block 12, and the front section of the shock wave induction block 12 is provided with an oblique shock wave. Ramp 12a (see image 3 As shown), the back of the slope 12a is a plane 12b, the inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com