Vertical-mill gearbox with pure-sliding bearing configuration structure

A technology of sliding bearing and configuration structure, applied in transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve problems such as difficulty in meeting the performance requirements of vertical mill gearboxes, and achieve high cost performance, high service life, and maintenance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

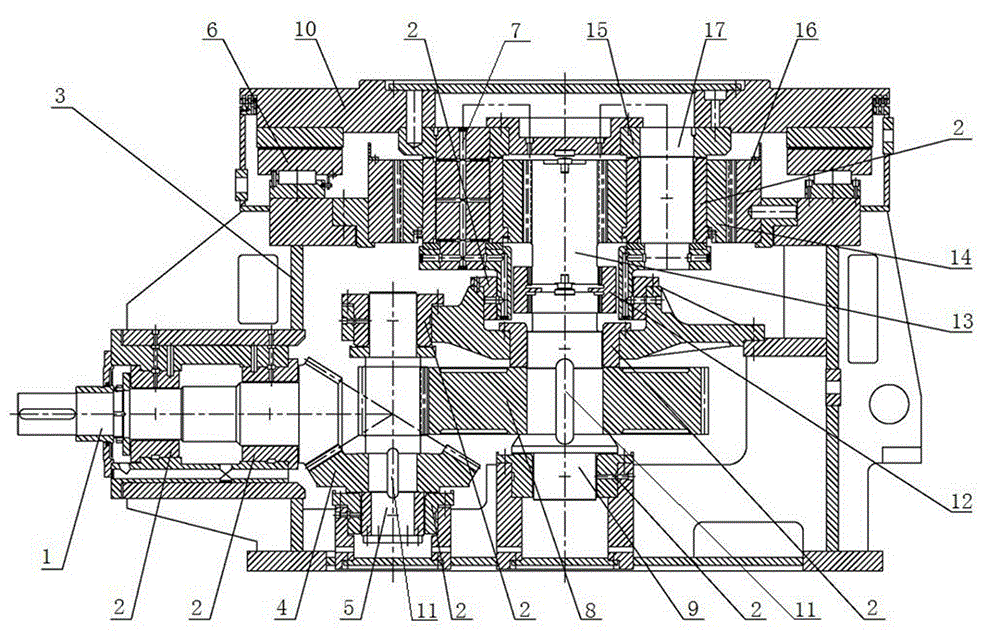

[0015] The accompanying drawings disclose the specific structure of an embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Depend on figure 1 It can be seen that the present invention includes a box body 3, an input stage bevel gear pair, a second stage parallel shaft cylindrical gear pair, an output stage planetary gear pair and an output flange 10, and the input stage bevel gear pair includes an input bevel gear shaft 1, Driven bevel gear 4; described second-stage parallel shaft cylindrical gear pair includes pinion shaft 5, driven bull gear 8, drum pinion shaft 9; described output stage planetary gear pair includes sun gear shaft 13, planetary gear 14. Inner ring gear 16, planetary wheel shaft 17, and planetary carrier 15; wherein: the output flange 10 is supported by a set of tilting pad thrust sliding bearings 6; other moving parts are supported by sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com