Combined firework barrel row transferring device

A combination of fireworks and transfer device technology, applied in the direction of pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of low work efficiency, high labor intensity, high production cost, etc., and achieve the effect of simple mechanism, low cost, and error-free mechanism work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

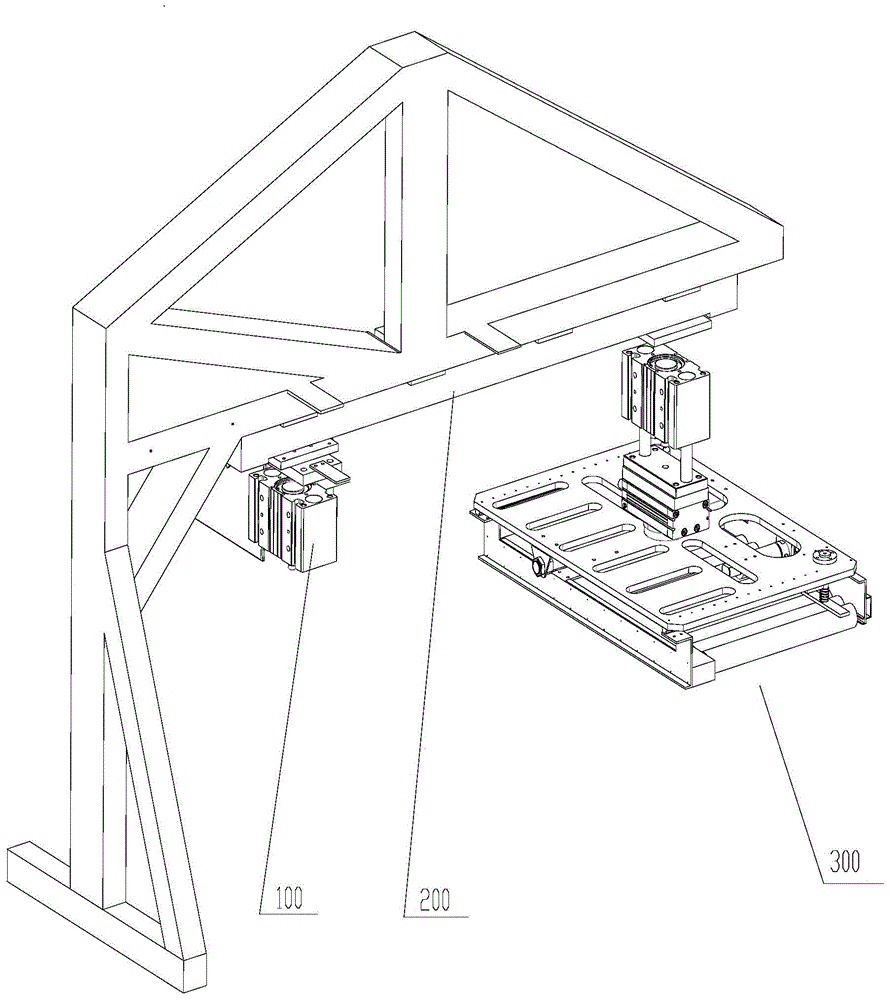

[0018] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the transfer device of the combined fireworks tube row includes a tube discharge pick-and-place mechanism 300 installed on the main rail 200, and the tube discharge pick-and-place mechanism 300 is integrated on the main drive mechanism 100 Under the action of the main rail 200, it moves repeatedly.

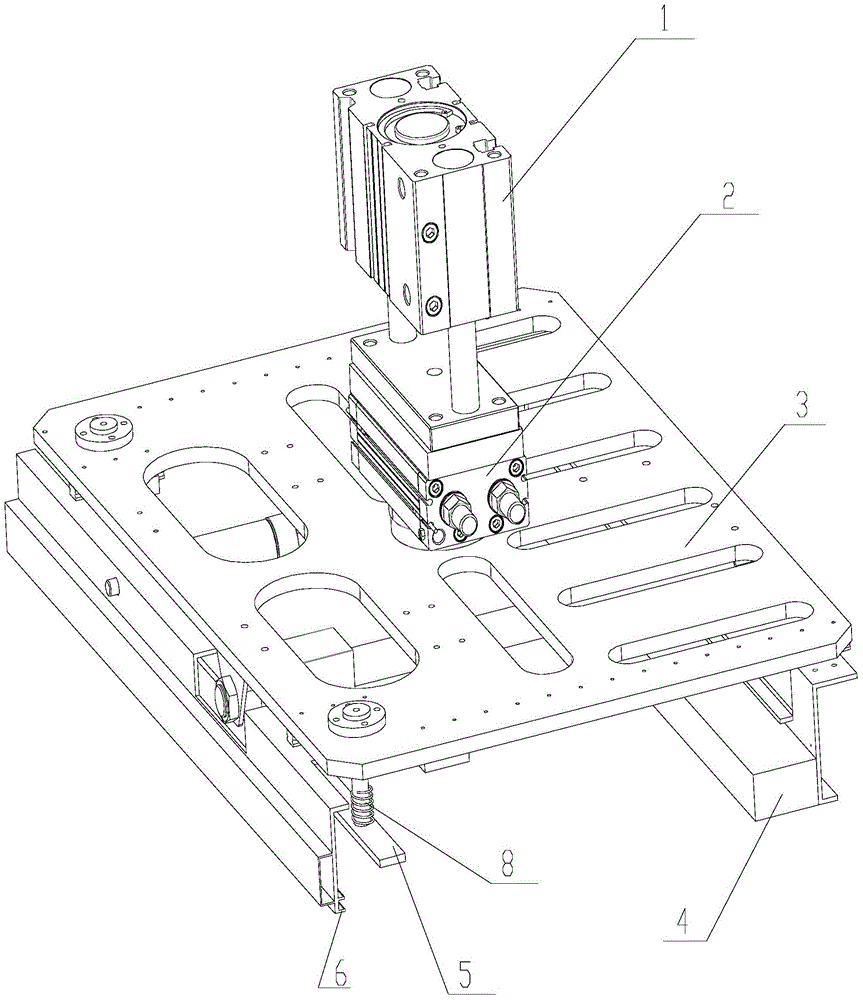

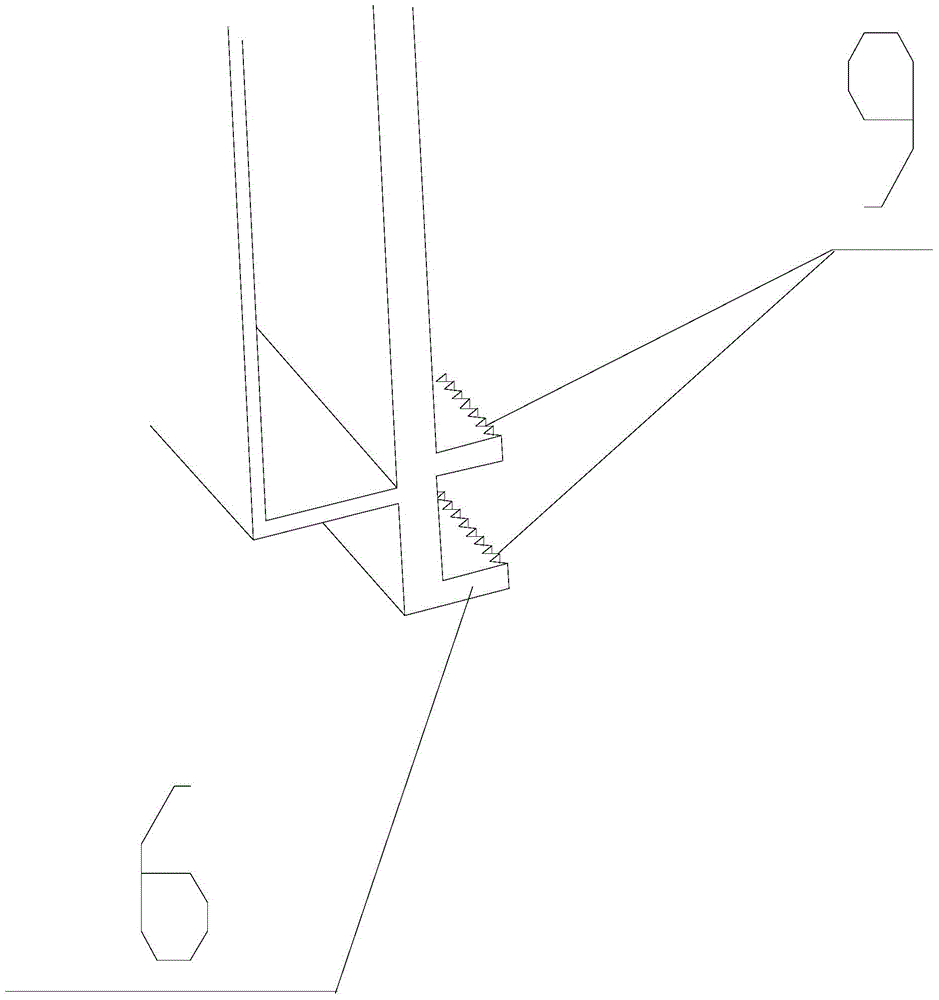

[0019] The cartridge discharge mechanism 300 includes a base plate 3, on which a lifting drive cylinder 1 and a rotating drive cylinder 2 are installed; on the opposite sides of the base plate 3, the first end clamping strip 4 and the fireworks tail end clamping bar are correspondingly installed. 6. The clamping strip 4 at the head end of the fireworks and the clamping strip 6 at the tail end of the fireworks move towards each other along the traverse guide rail 7 under the action of the traverse drive mechanism (not shown in the figure), and clamp the cylinder along the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com