A scissors-type angle measuring device and angle measuring method

An angle measurement device, scissors-type technology, applied in angle/taper measurement, etc., can solve the problems of not being able to reflect the change of angle intuitively, affecting the measurement accuracy, and complicated measurement steps, so as to improve measurement efficiency, improve measurement accuracy, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A scissors-type angle measuring device

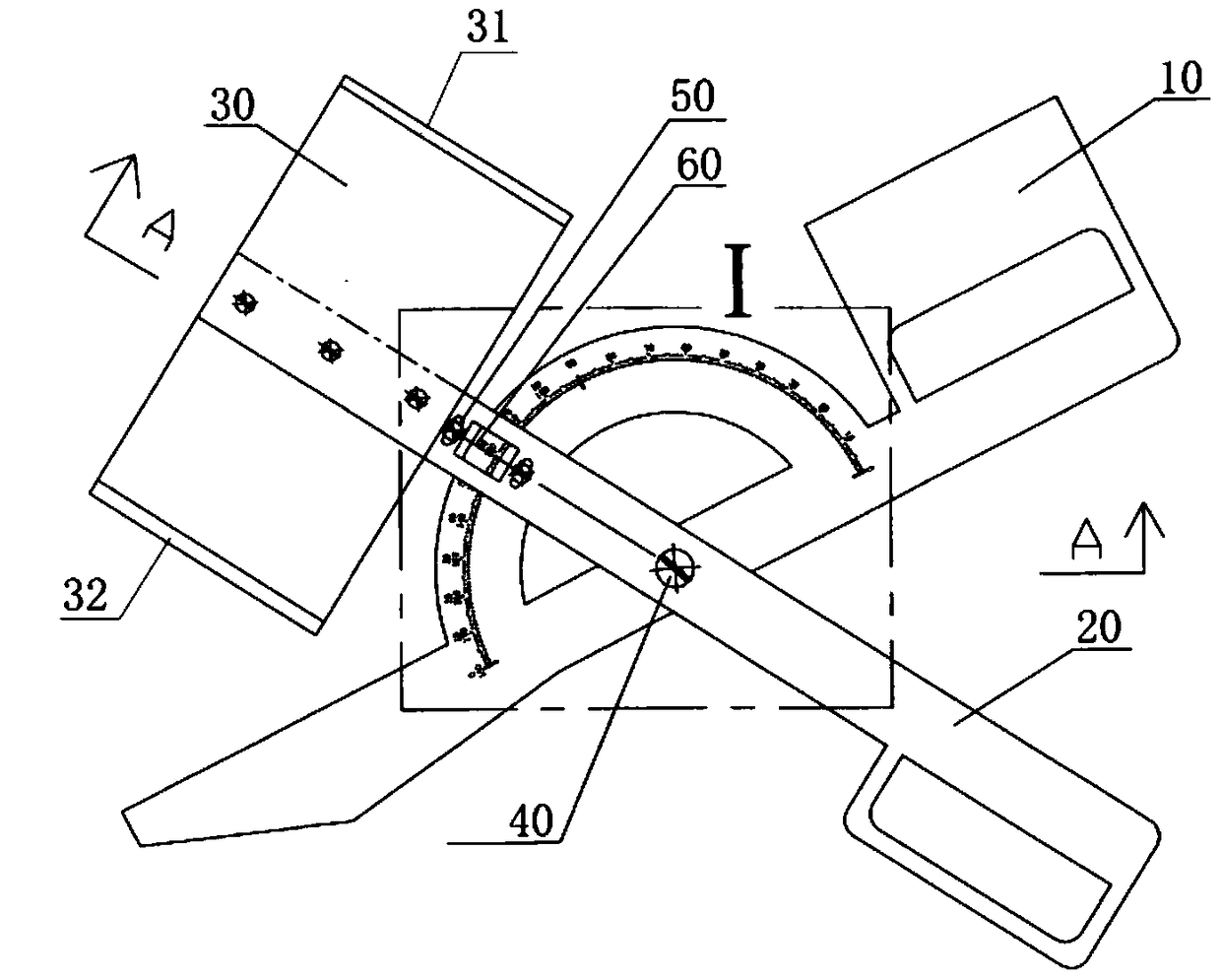

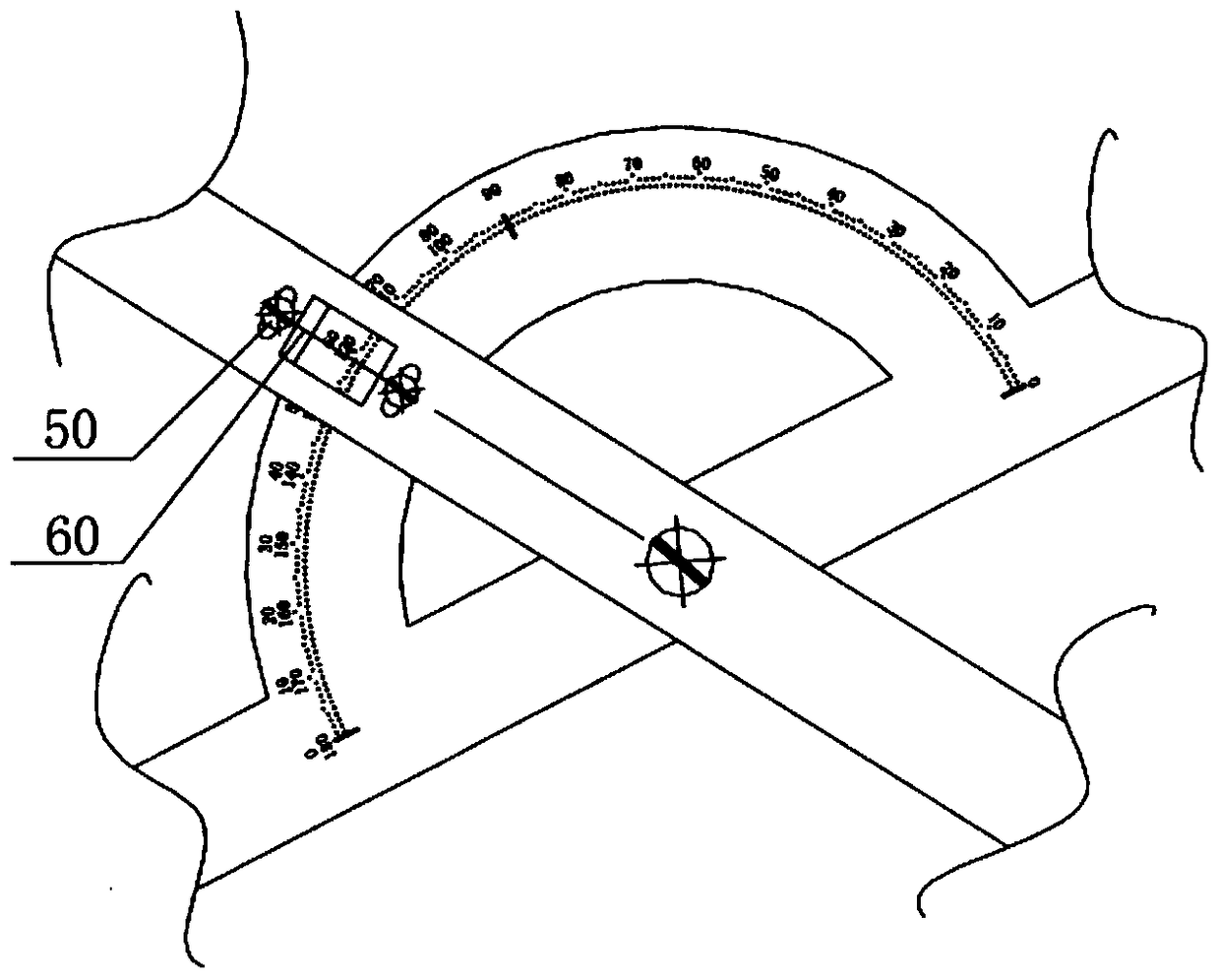

[0034] like Figure 1-Figure 6 As shown, the scissors-type angle measuring device is composed of component I (10), component II (20), positioning block (30), rotating shaft (40), sliding screw (50) and copper wire (60).

[0035] like Figure 5 As shown, one end of component I (10) is provided with a handle part I (11), and an obtuse angle reference plane (13) is provided on the handle part I (11). The middle part is provided with an angle dial (12), and an angle mark is arranged on the angle dial (12). The other end is the acute angle datum plane I (14).

[0036] like Image 6 As shown, one end of component II (20) is provided with a handle part II (21), the middle part is provided with a window (22) for reading the angle, and the two ends of the window (22) are provided with oblong sliding grooves (23). II (20) is provided with a calibration line (24) for positioning.

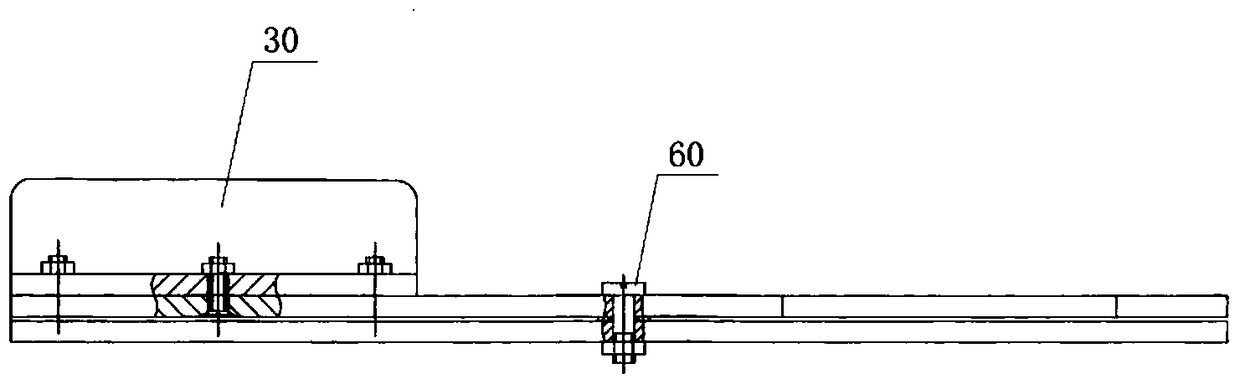

[0037] The positioning block (30) is ins...

Embodiment 2

[0041] Embodiment 2 An angle measurement method

[0042] Adopt the angle measuring device of embodiment 1, method is as follows:

[0043] 1) Visually measure the angle of the part to be tested;

[0044] 2) if Figure 7 As shown, if the part to be measured (70) is an acute angle, fit the two sides of the part to the acute-angle reference plane I (14) of the component I (10) and the acute-angle reference plane II (32) of the positioning block (30) respectively, and pass Window, read the angle scale corresponding to the copper wire;

[0045] 3) if Figure 8 As shown, if the part to be measured (80) is an obtuse angle, fit the two sides of the part to the obtuse reference plane I (13) of the component I (10) and the obtuse reference plane II (31) of the positioning block (30) respectively, and pass Window, read the angle scale corresponding to the copper wire.

[0046] When measuring, you can operate the two handles with one hand, clamp the positioning end on the bending edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com