Experiment device and experiment method for detecting flow regularity of granular mixtures in silo

An experimental device and particle technology, which can be used in measurement devices, flow characteristics, instruments, etc., can solve problems such as large dispersion of results, difficulty in determining friction coefficient, and inability to be used as a design, so as to facilitate measurement and research, and facilitate disassembly and assembly. , the experimental effect is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

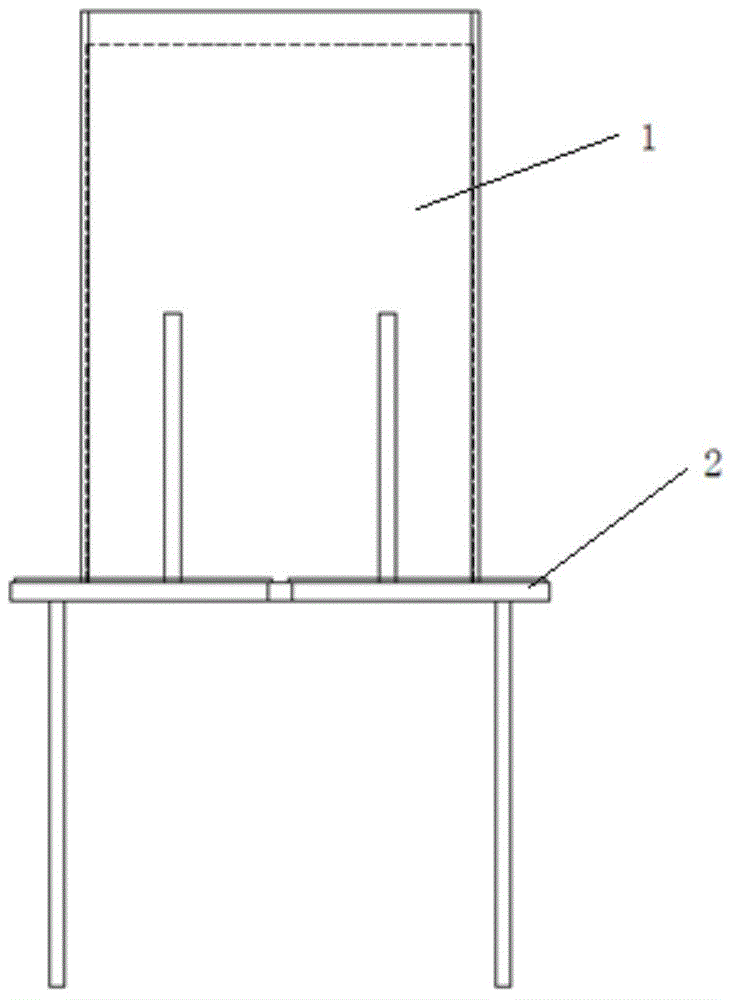

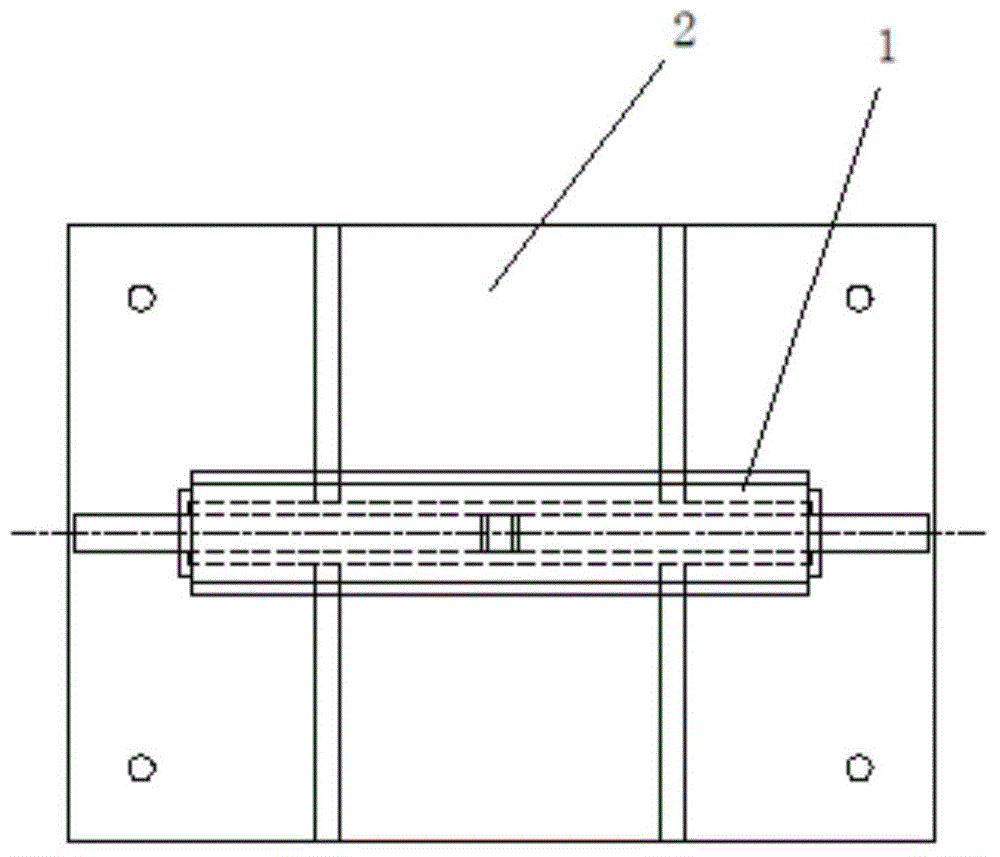

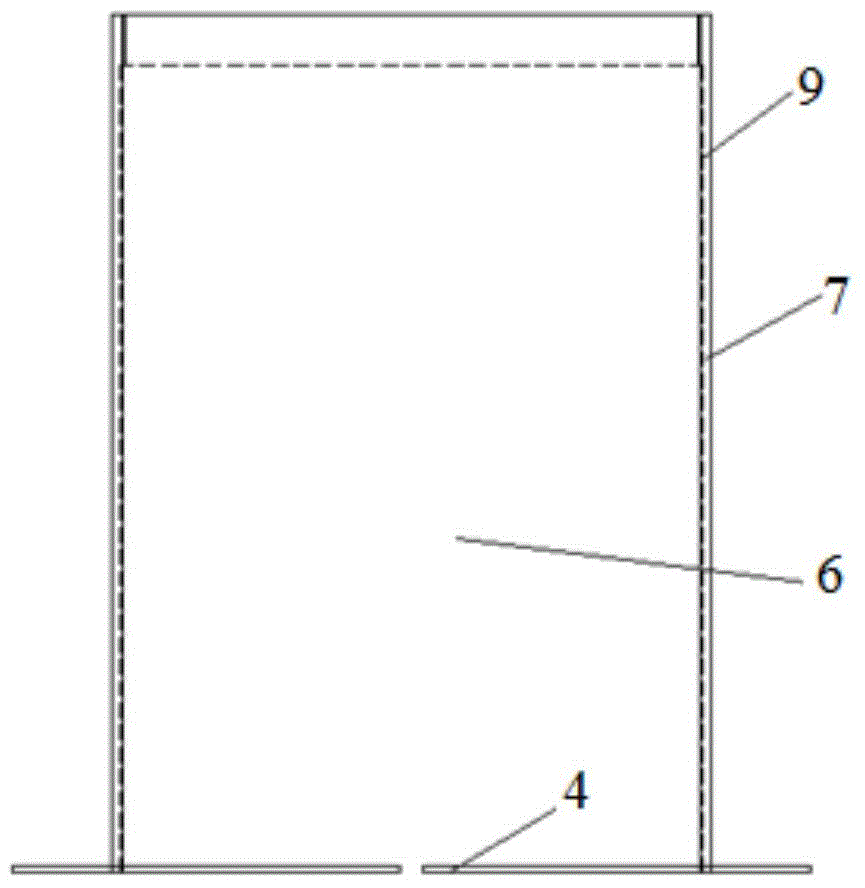

[0040]As shown in the figure, an experimental device for measuring the flow law of granular materials in a silo has a supporting mechanism 2, a silo main body 1 arranged on the supporting mechanism 2, and is used for supplying granular materials to the silo main body 1 The supply mechanism 3 of the body; the three parts of the silo main body 1, the support mechanism 2 and the supply mechanism 3 can be separated freely. The silo main body 1 is composed of front and rear plexiglass retaining walls 6 and rear plexiglass retaining walls, left and right panels 7 on both sides, unloading mechanism 4 at the bottom, left and right panels The two sides of the inner wall of 7 are respectively provided with cutting grooves I9 for installing the positive plexiglass retaining wall 6 and the rear plexiglass retaining wall. The plate 7 is slidingly fitted, and there is a cutting groove II8 under the left and right plate 7, the width of the cutting groove II8 matches the width of the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com