A Coal Sample Viscosity Discrimination Method for Coal Sample Collection and Production Integration

A discriminating method, coal sample sampling technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of high labor intensity, poor accuracy, long cycle, etc., and achieve simple operation, high accuracy, meet the accuracy requirements and reliability The effect of sexual demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

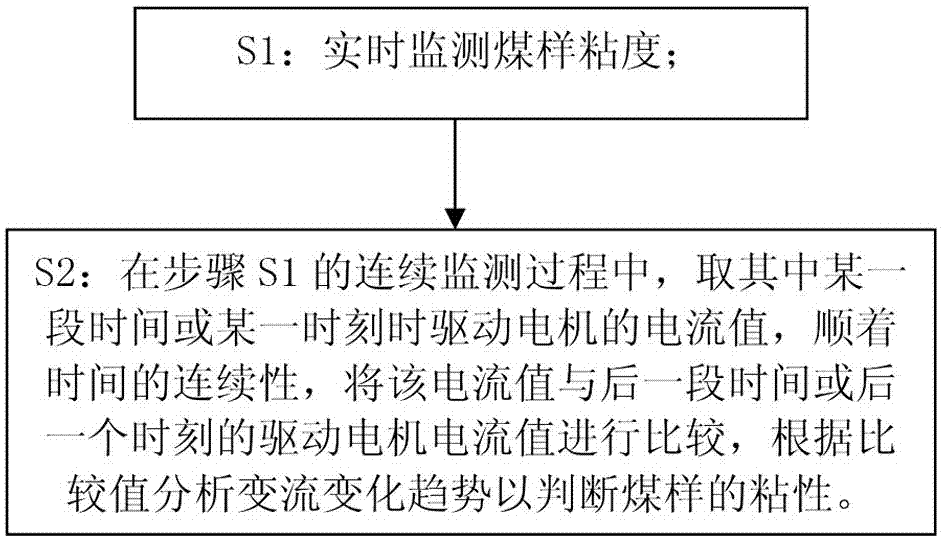

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

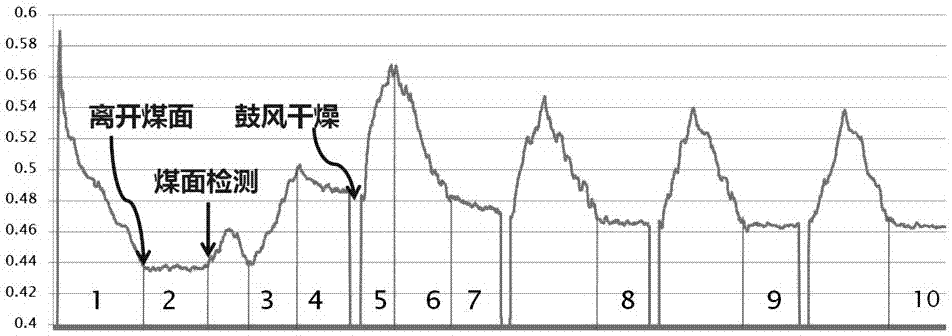

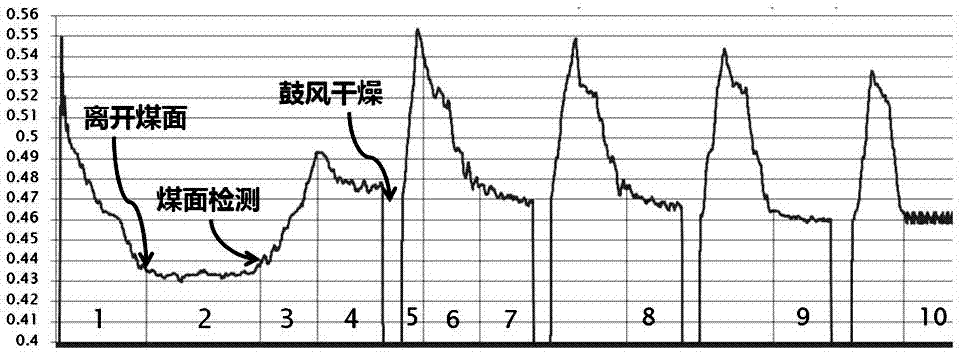

[0017] The coal sample viscosity discrimination method for the integration of coal sample collection and production in the present invention is based on the following principle: for the coal sample used for detection, the main reason is that the viscosity of the detected coal sample is different due to the difference in humidity. For coal samples with different viscosities, when the scraping operation is performed, the resistance of the same volume of coal samples is different, so the load on the driving motor used for the scraping operation will also be different, which will cause the real-time work of the driving motor. The current is different. For this reason, the present invention just judges the viscosity of coal samples according to the different electric currents of the drive motors in the process of rotating and sweeping diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com