Patents

Literature

36 results about "Sample viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

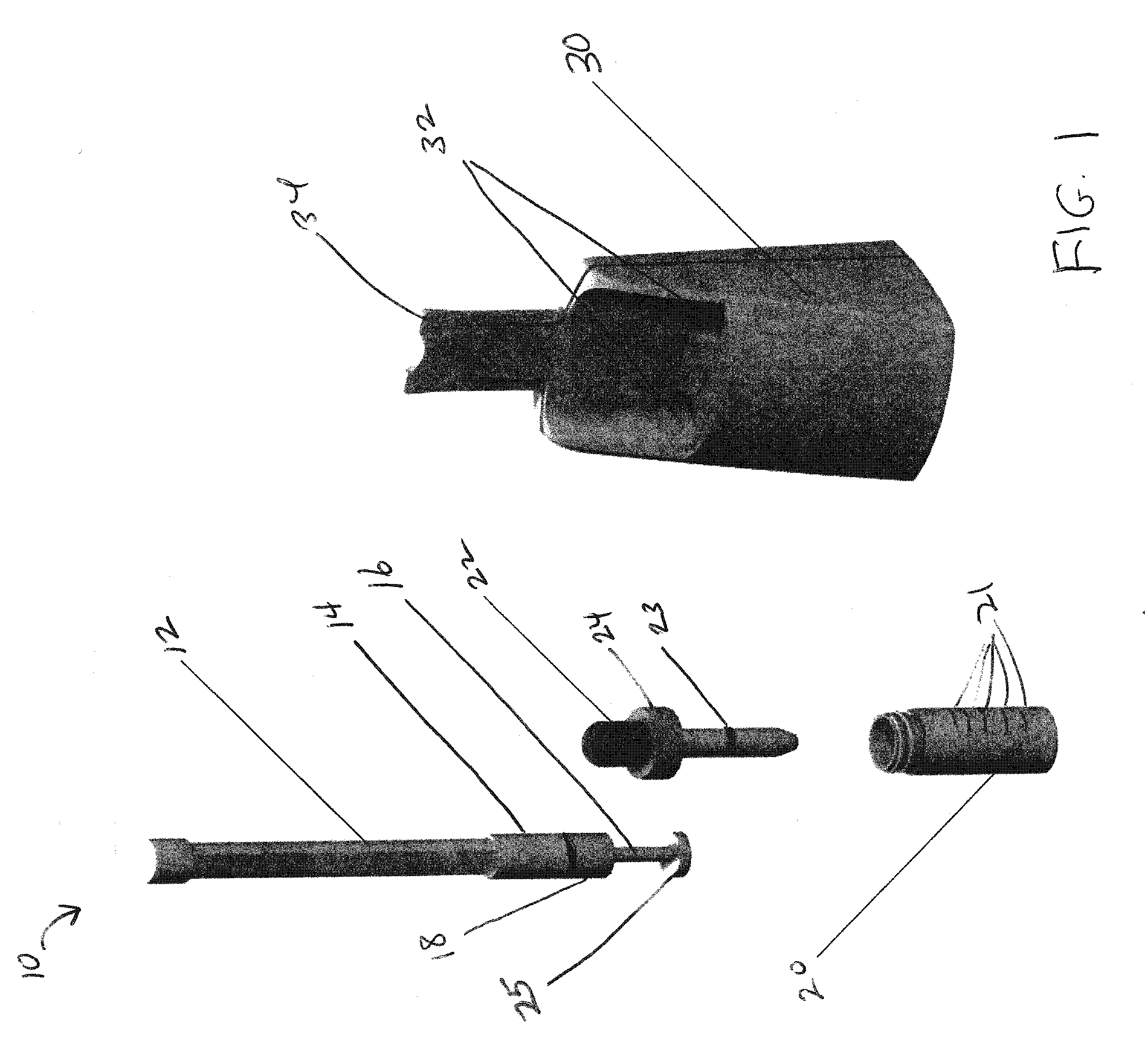

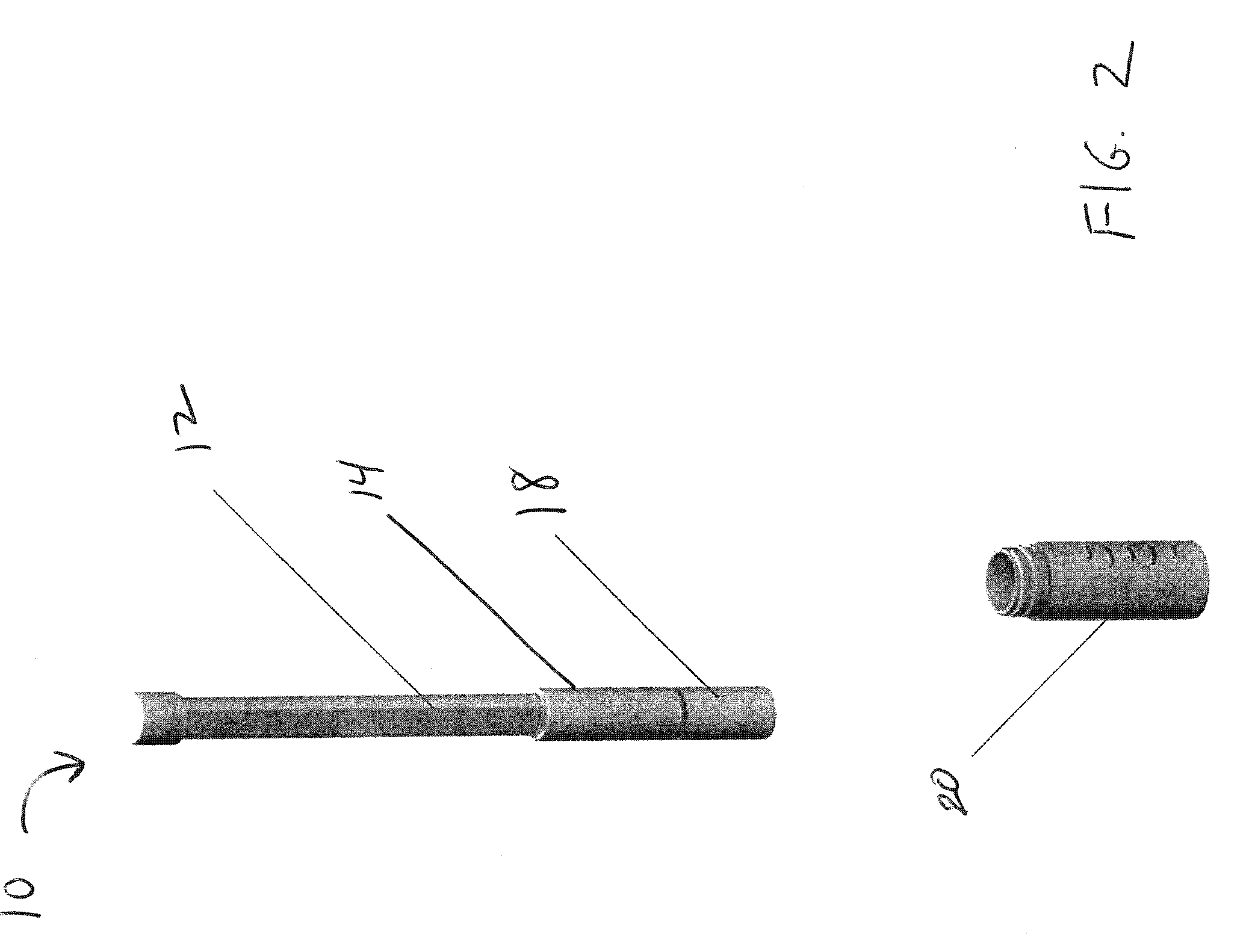

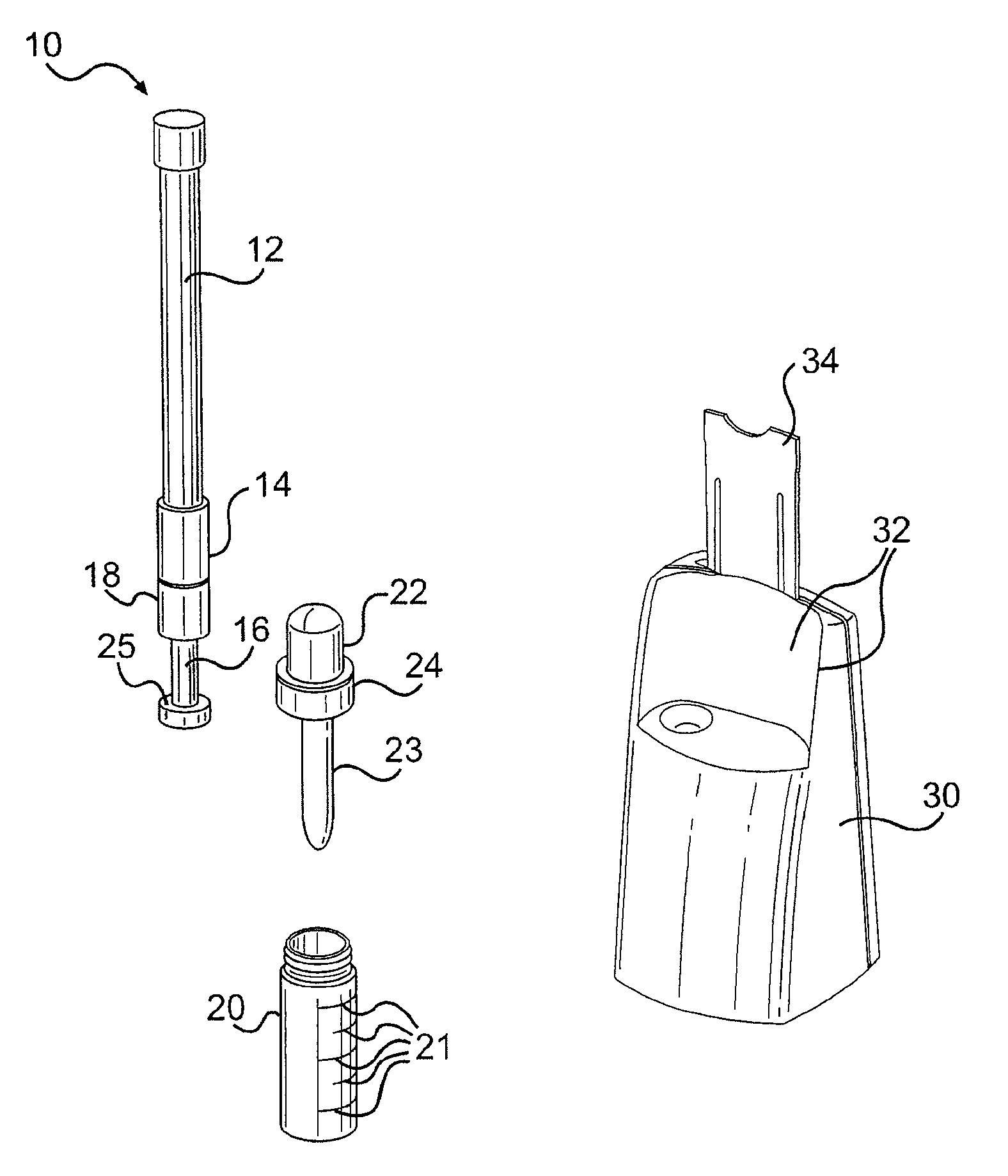

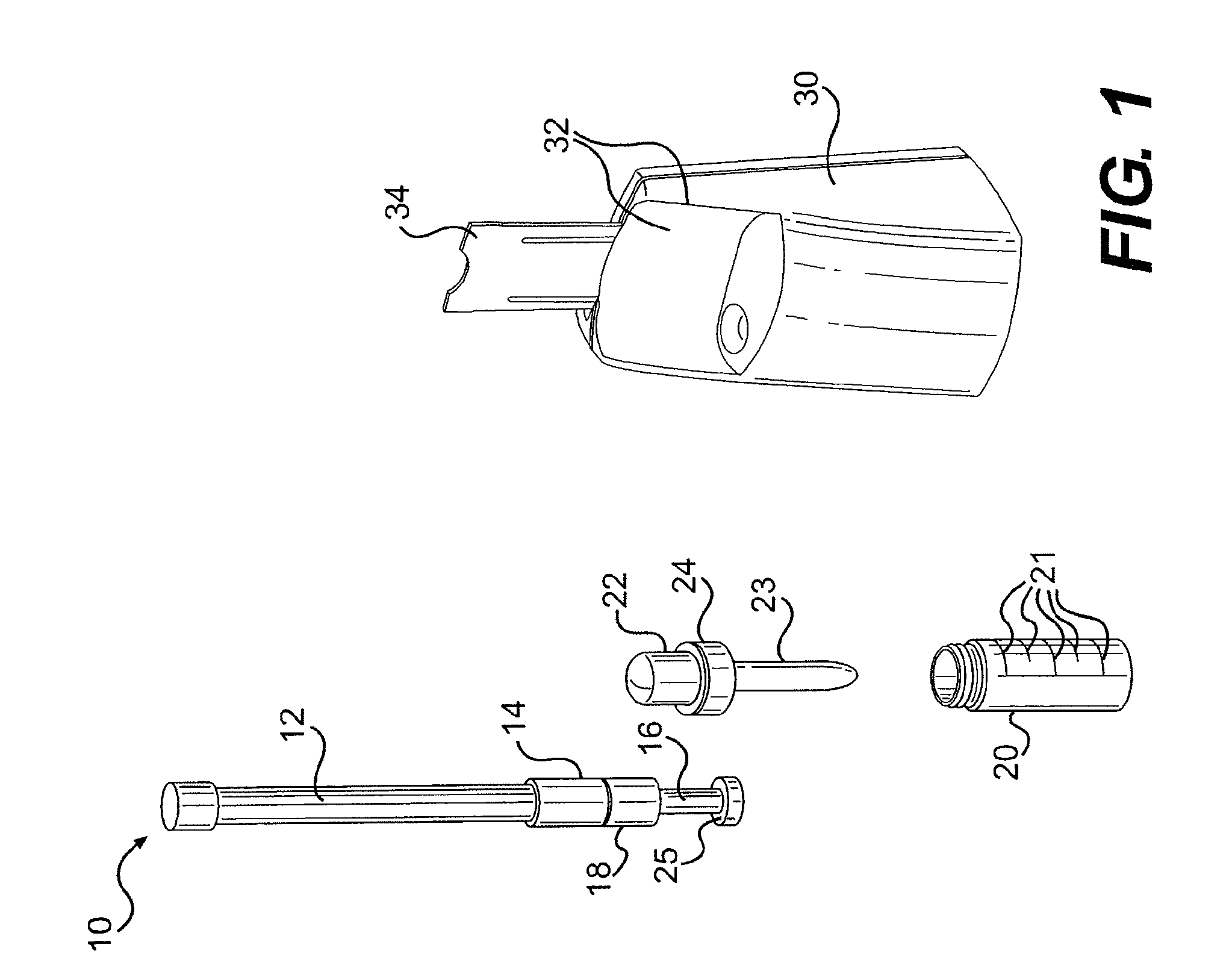

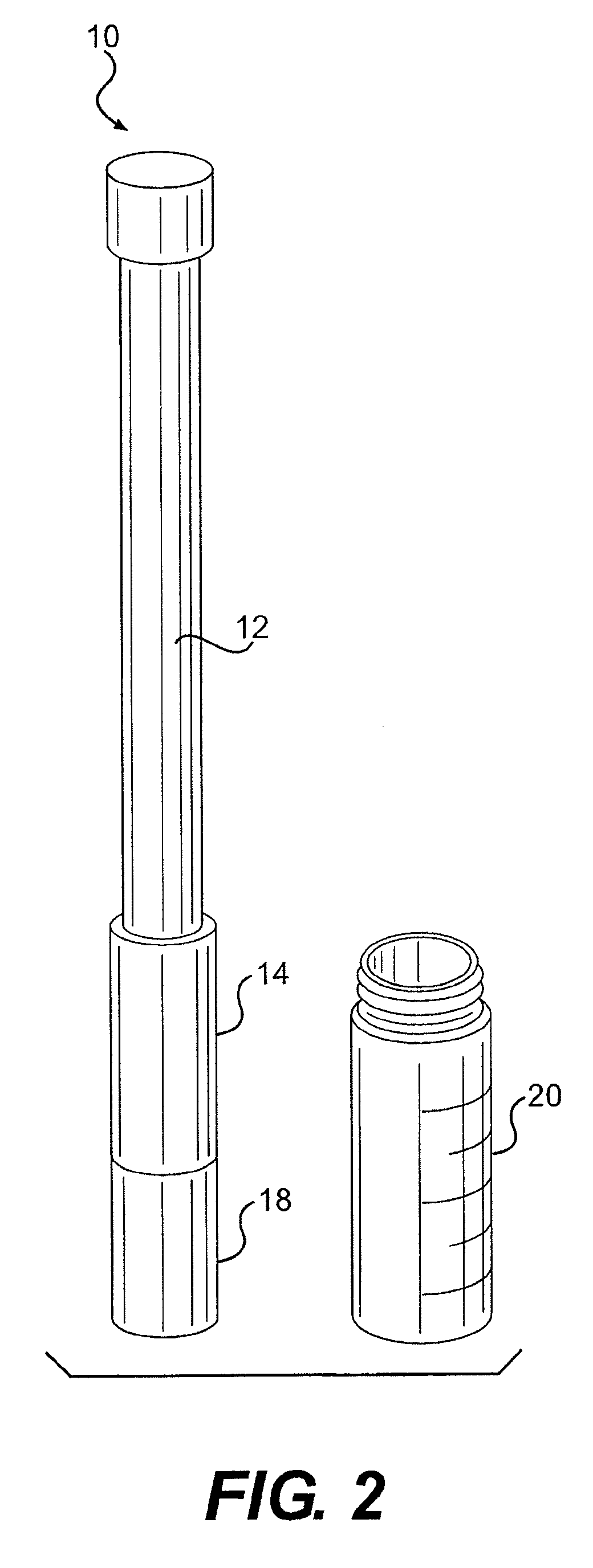

Extraction method and apparatus for high-sensitivity body fluid testing device

ActiveUS20080166820A1Rapid and efficient mannerQuick and accurate testBioreactor/fermenter combinationsBiological substance pretreatmentsBottleSaliva

An extraction method and apparatus is provided for obtaining quick, safe and highly sensitive testing of any of a variety of body fluids including saliva, blood, urine or other fluids for drugs of abuse or other analytes. The apparatus includes a latchable extraction wand for obtaining body fluid samples from a subject which is adapted to maximize the portion of the body fluid sample that will go into a graduated bottle containing a buffer solution, and a testing device wherein the sample will be received and into which test strips can be inserted to determine levels of drugs of abuse or other analyte in the sample. In one of the methods of the invention, energy is imparted to the sample and buffer solution, such as by shaking, and this facilitates the reduction of sample viscosity, such as by promoting the breakdown of mucins when the sample is saliva.

Owner:HEALGEN SCI LLC

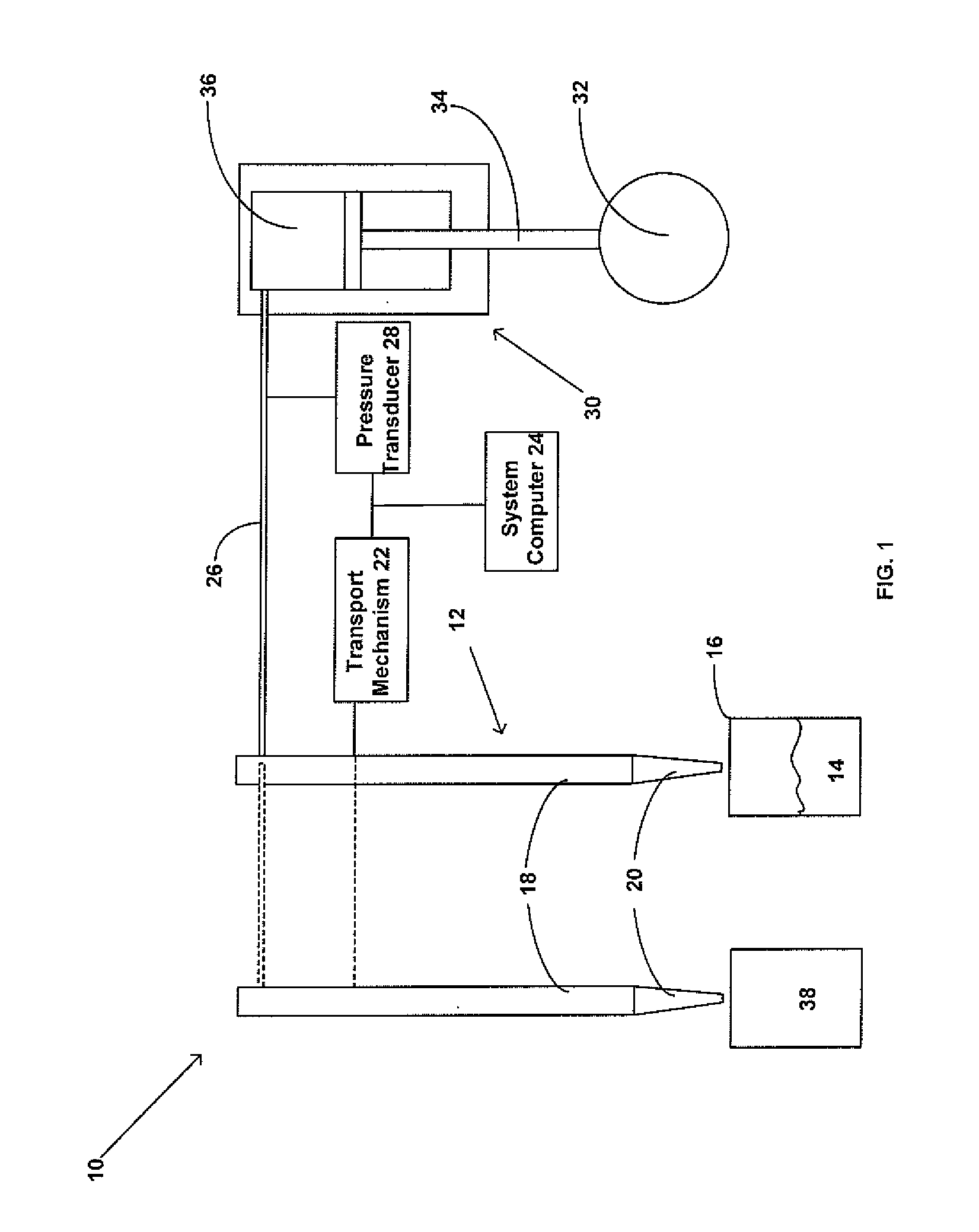

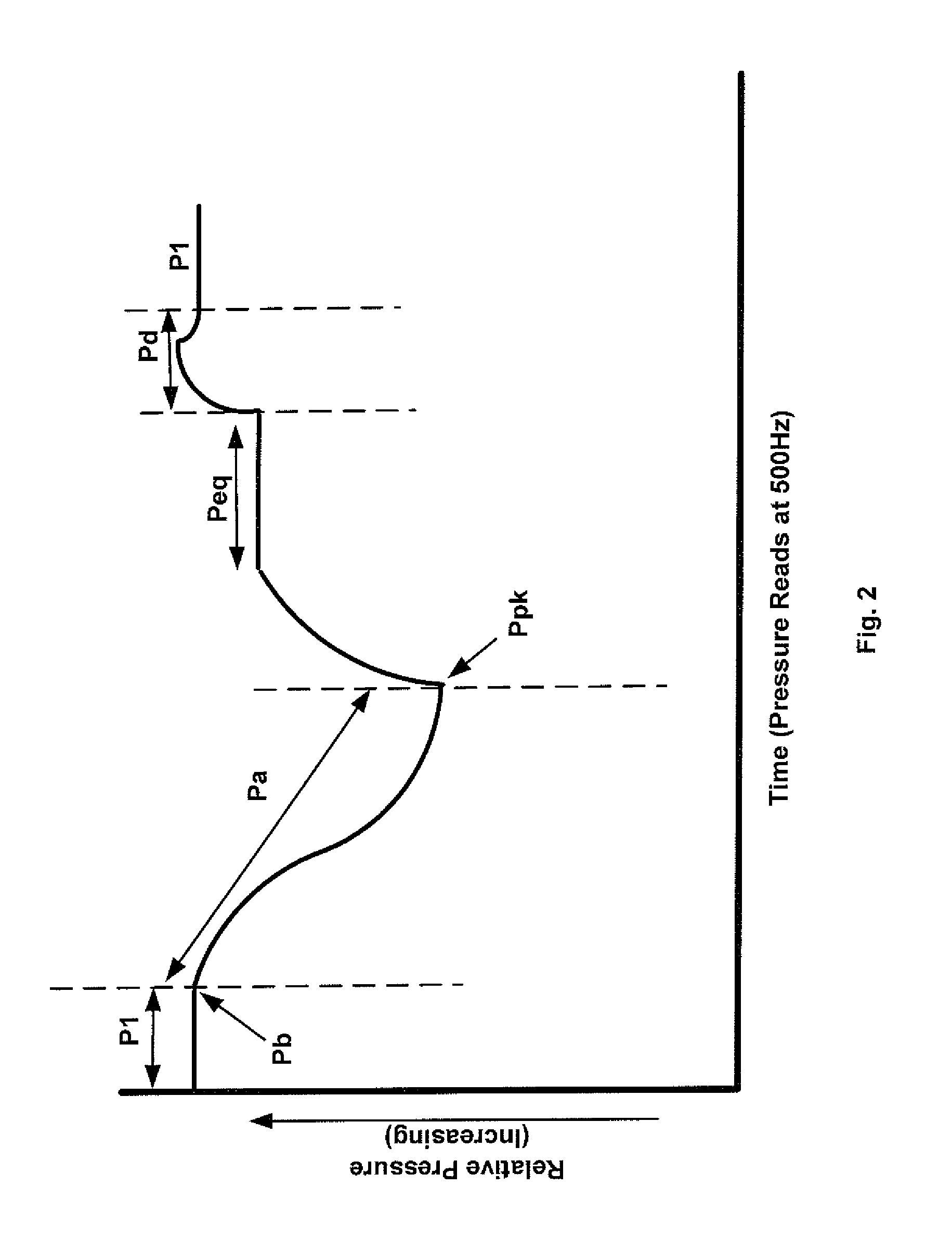

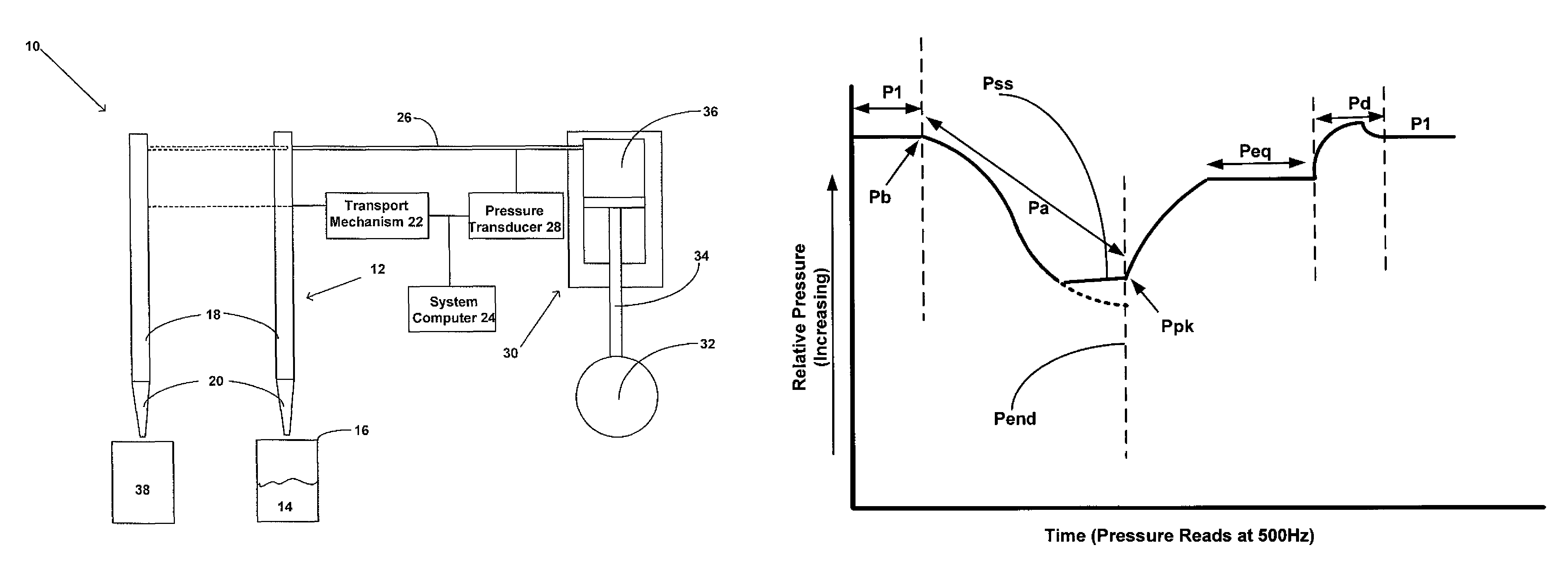

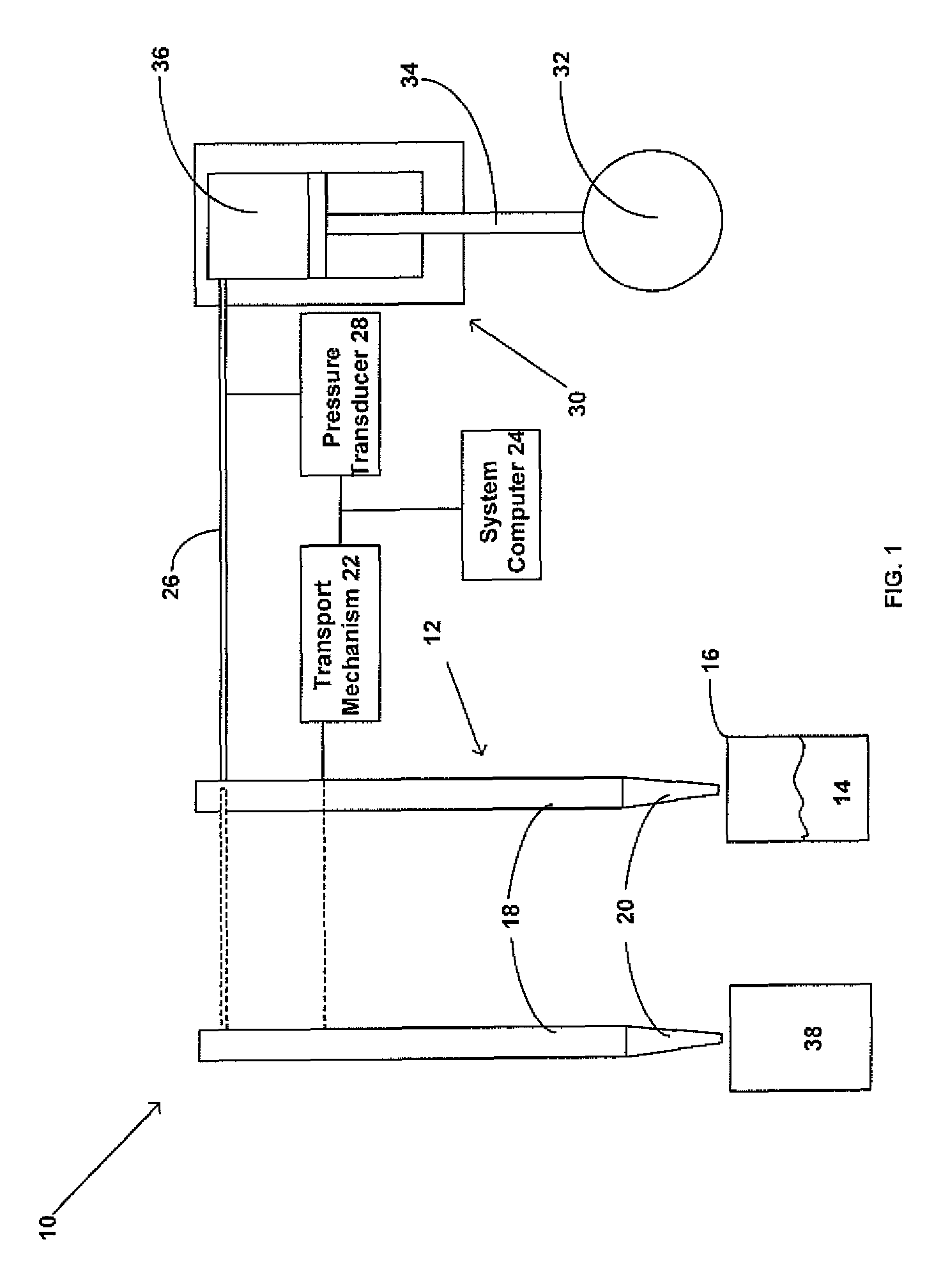

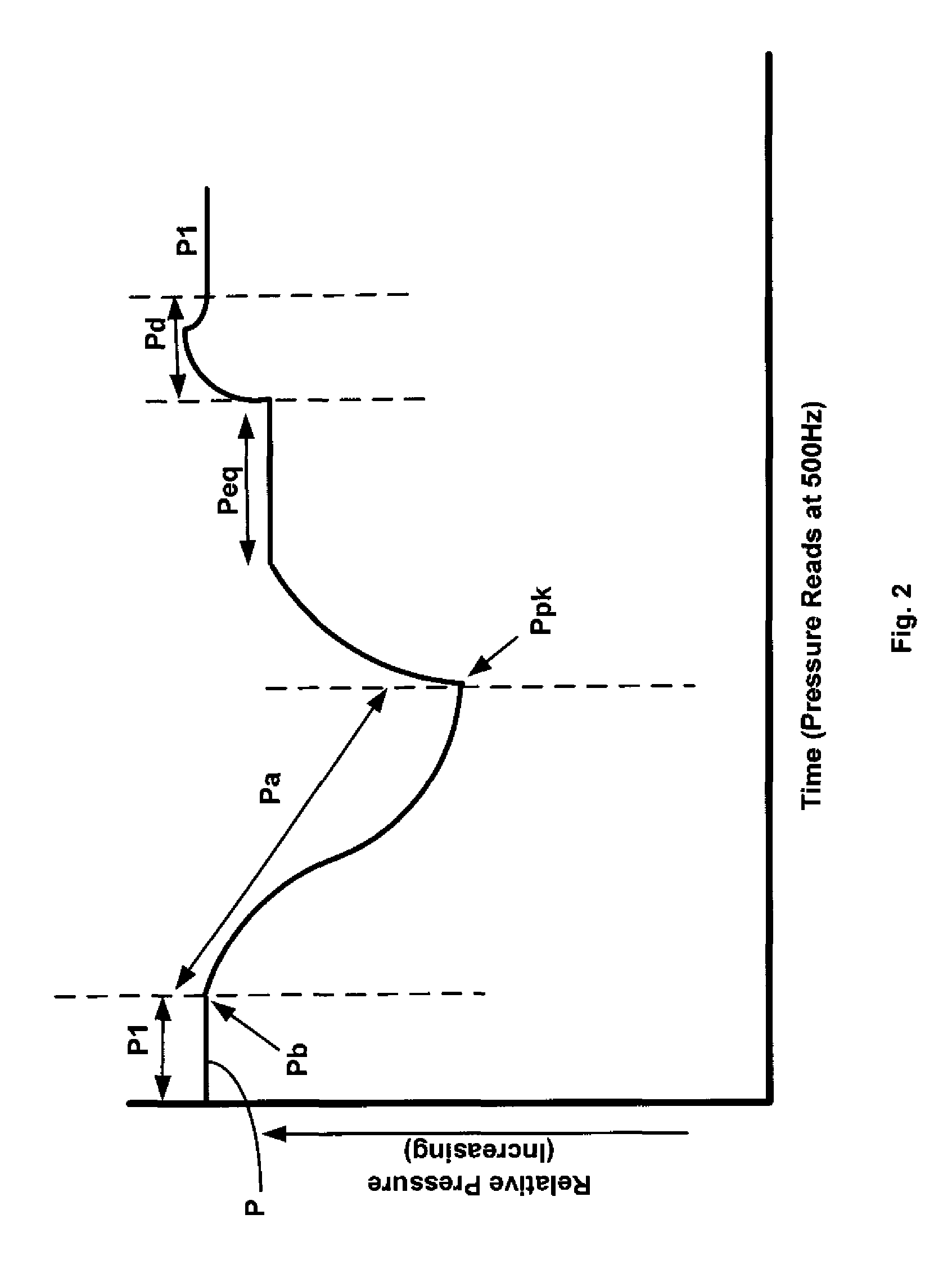

Differentiating Between Abnormal Sample Viscosities and Pipette Clogging During Aspiration

ActiveUS20090266149A1High viscosityMinimum sample volumeTesting/calibration apparatusMaterial analysis by optical meansPipetteSample viscosity

A method for differentiating between a liquid sample having clogs therein and a liquid sample having an abnormally elevated viscosity during a liquid aspiration process by relating the ratio between the maximum negative pressure during aspiration and an equilibrium pressure prior to dispensation to viscosity.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

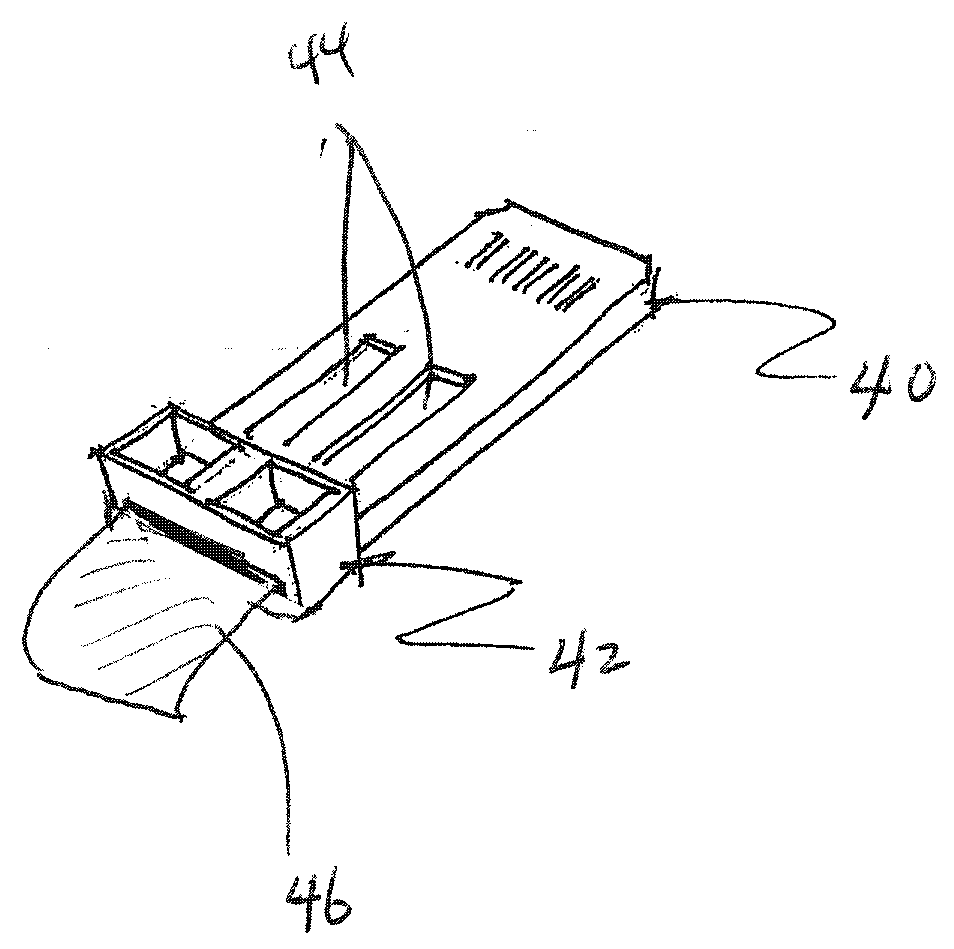

Apparatus for high-sensitivity body fluid testing device

ActiveUS7695953B2Rapid and efficient mannerQuick and accurate testBioreactor/fermenter combinationsBiological substance pretreatmentsBottleSaliva

An extraction method and apparatus is provided for obtaining quick, safe and highly sensitive testing of any of a variety of body fluids including saliva, blood, urine or other fluids for drugs of abuse or other analytes. The apparatus includes a latchable extraction wand for obtaining body fluid samples from a subject which is adapted to maximize the portion of the body fluid sample that will go into a graduated bottle containing a buffer solution, and a testing device wherein the sample will be received and into which test strips can be inserted to determine levels of drugs of abuse or other analyte in the sample. In one of the methods of the invention, energy is imparted to the sample and buffer solution, such as by shaking, and this facilitates the reduction of sample viscosity, such as by promoting the breakdown of mucins when the sample is saliva.

Owner:HEALGEN SCI LLC

Differentiating between abnormal sample viscosities and pipette clogging during aspiration

A method for differentiating between a liquid sample having clogs therein and a liquid sample having an abnormally elevated viscosity during a liquid aspiration process by relating the ratio between the maximum negative pressure during aspiration and an equilibrium pressure prior to dispensation to viscosity.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

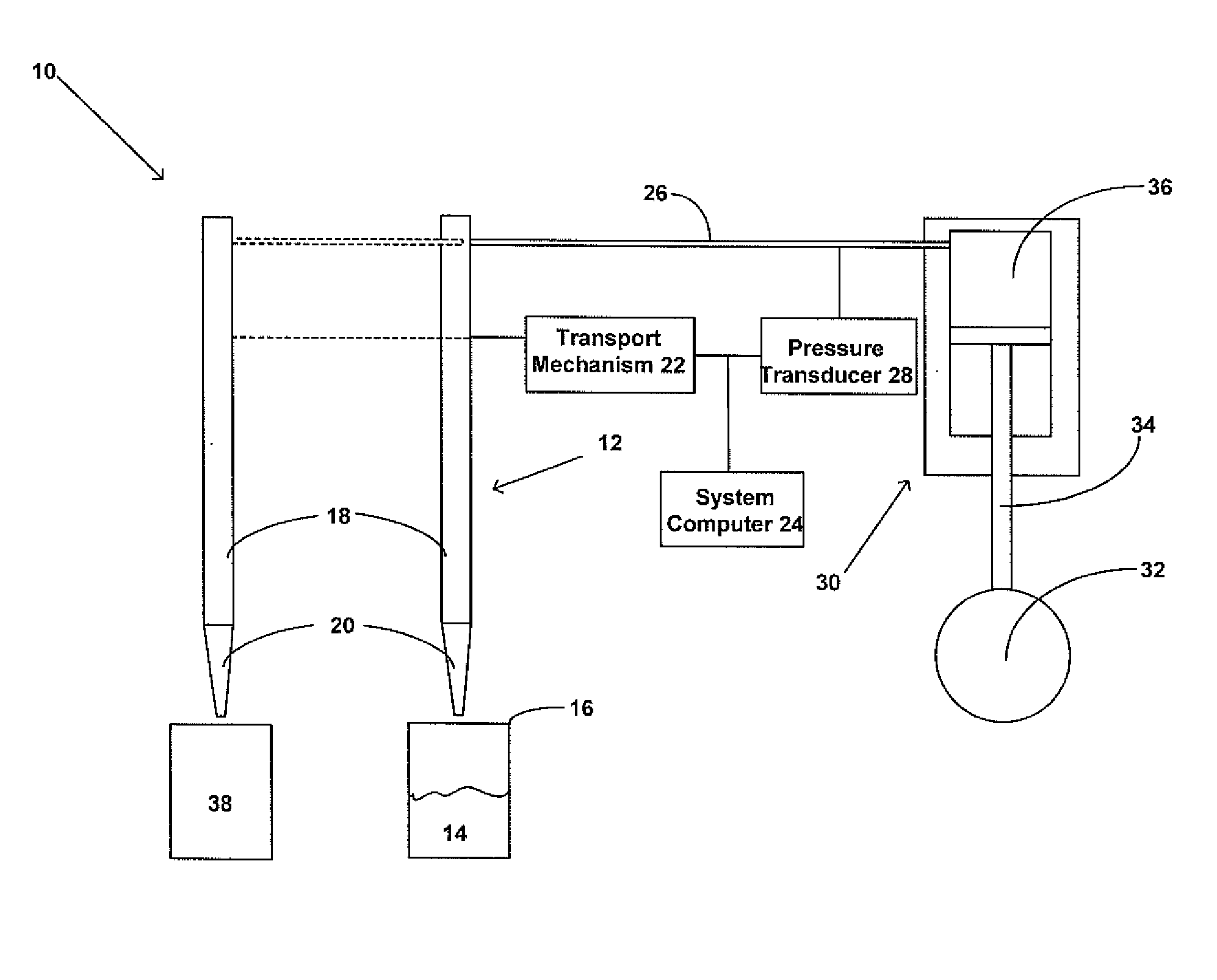

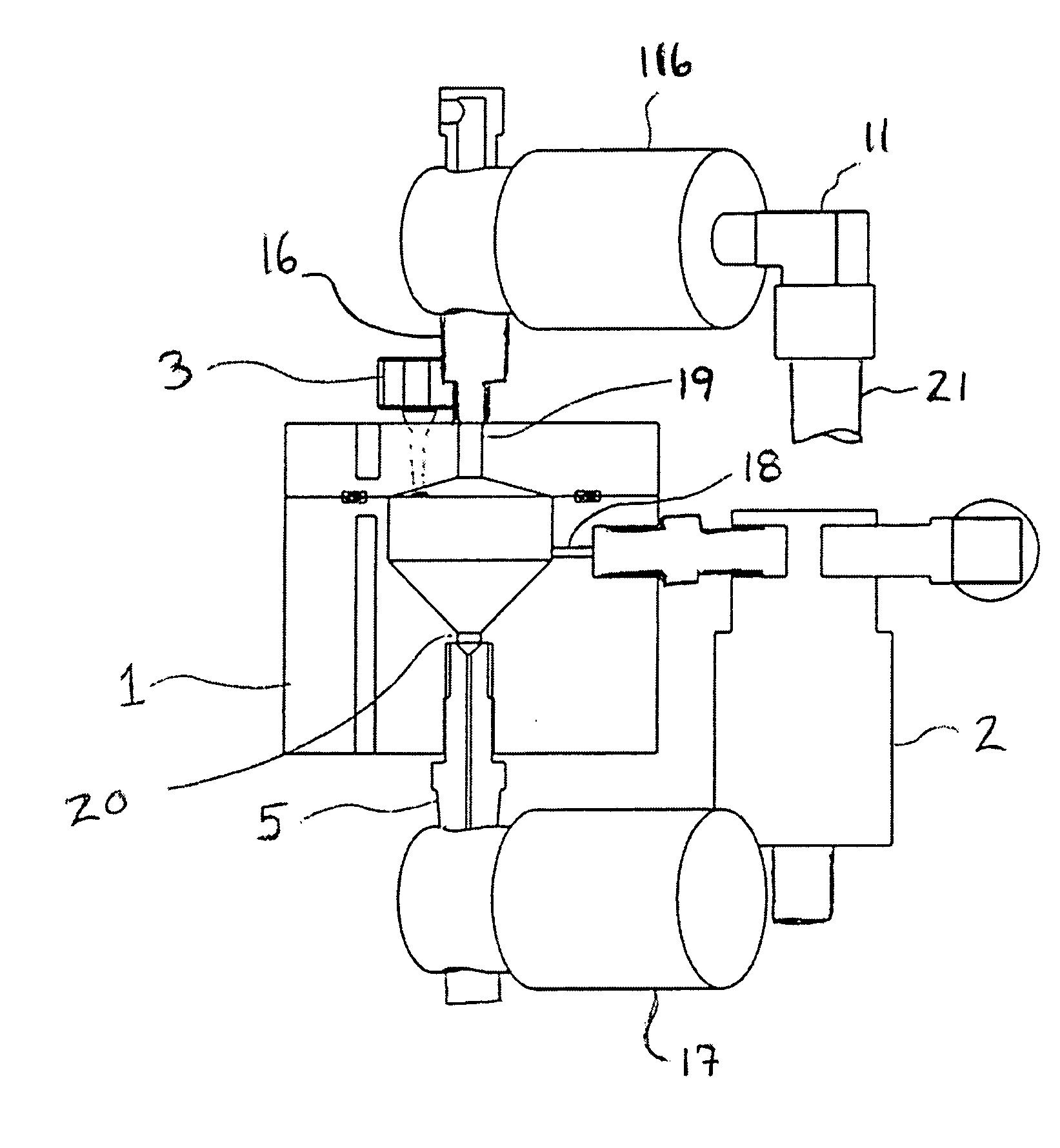

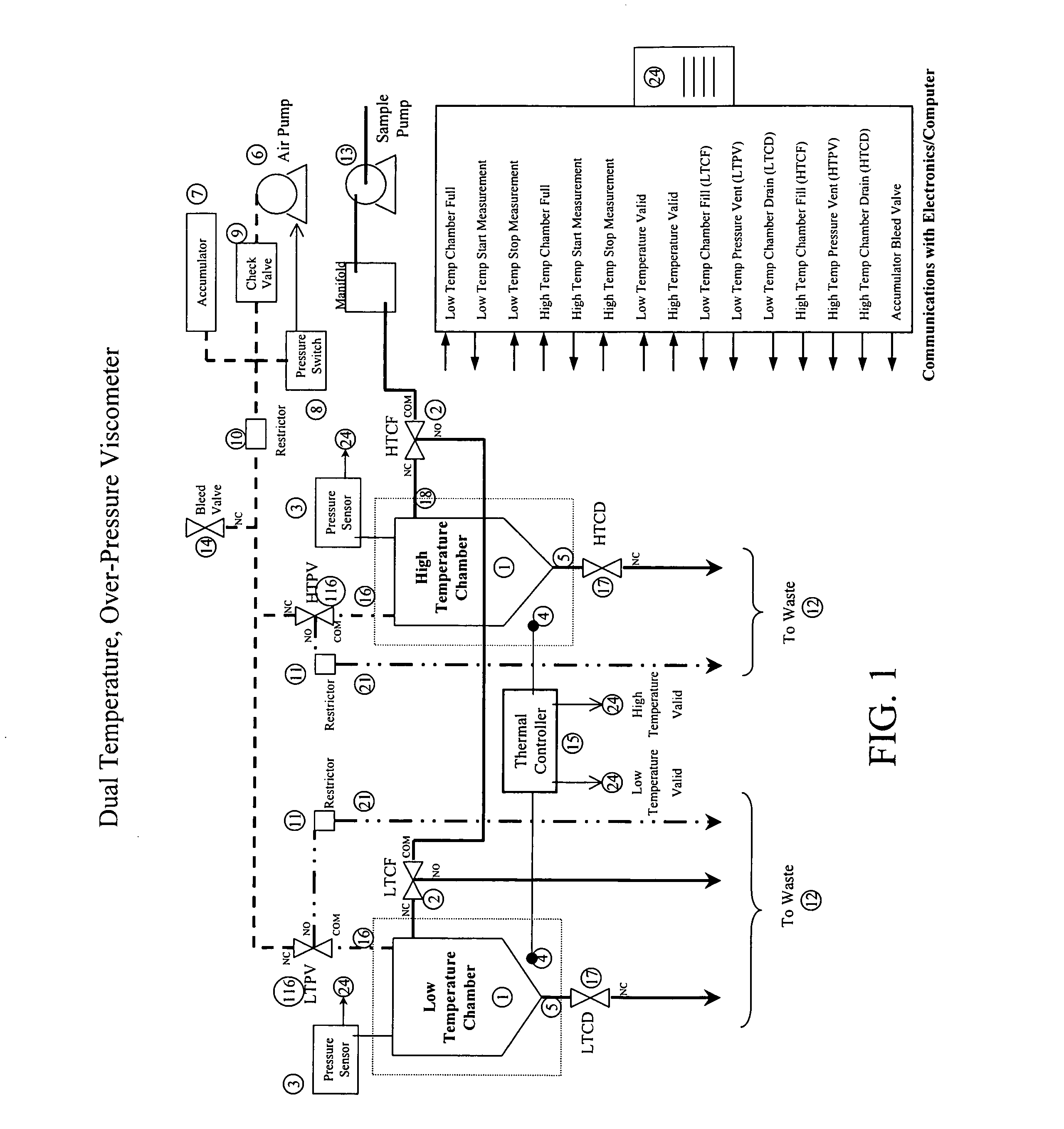

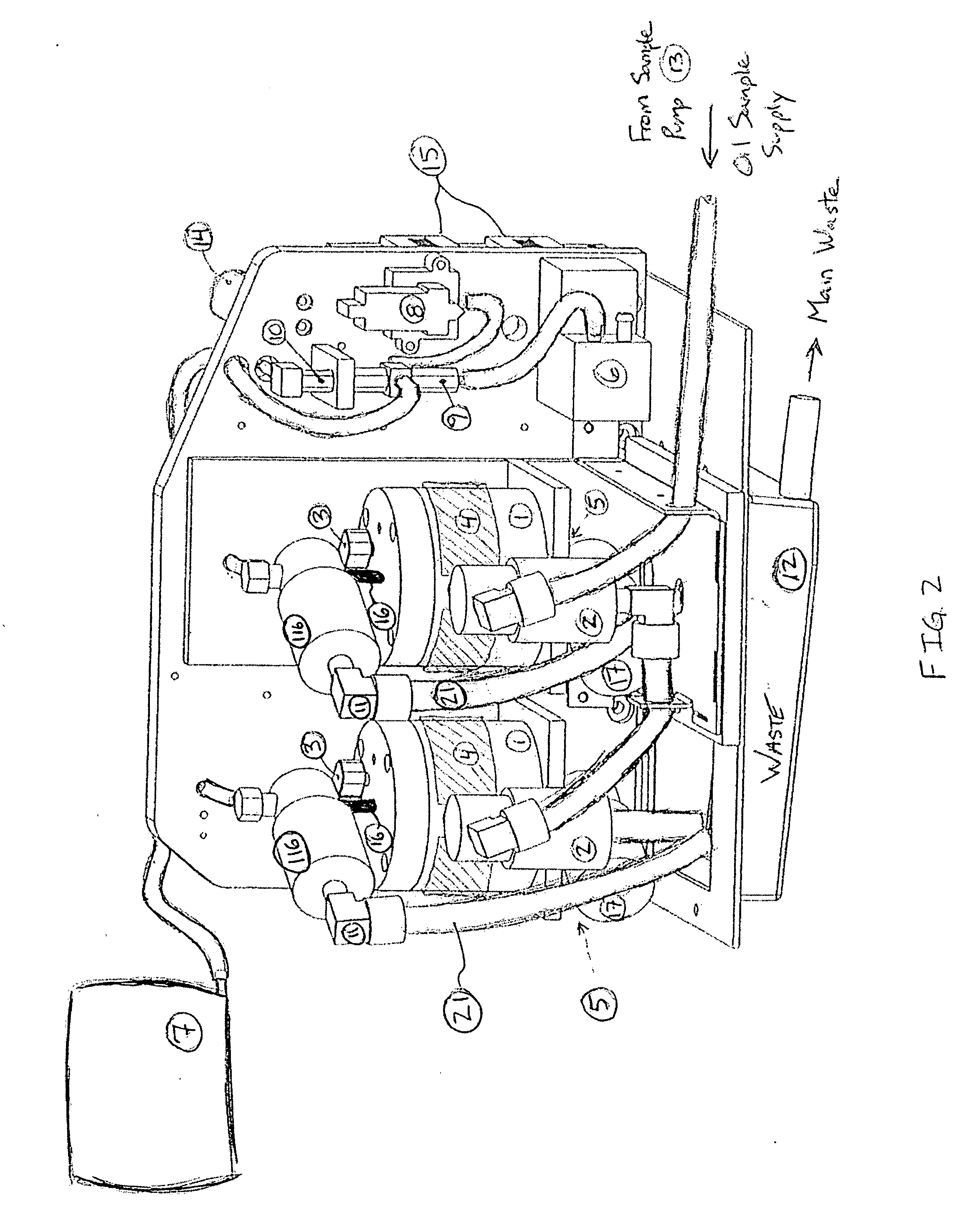

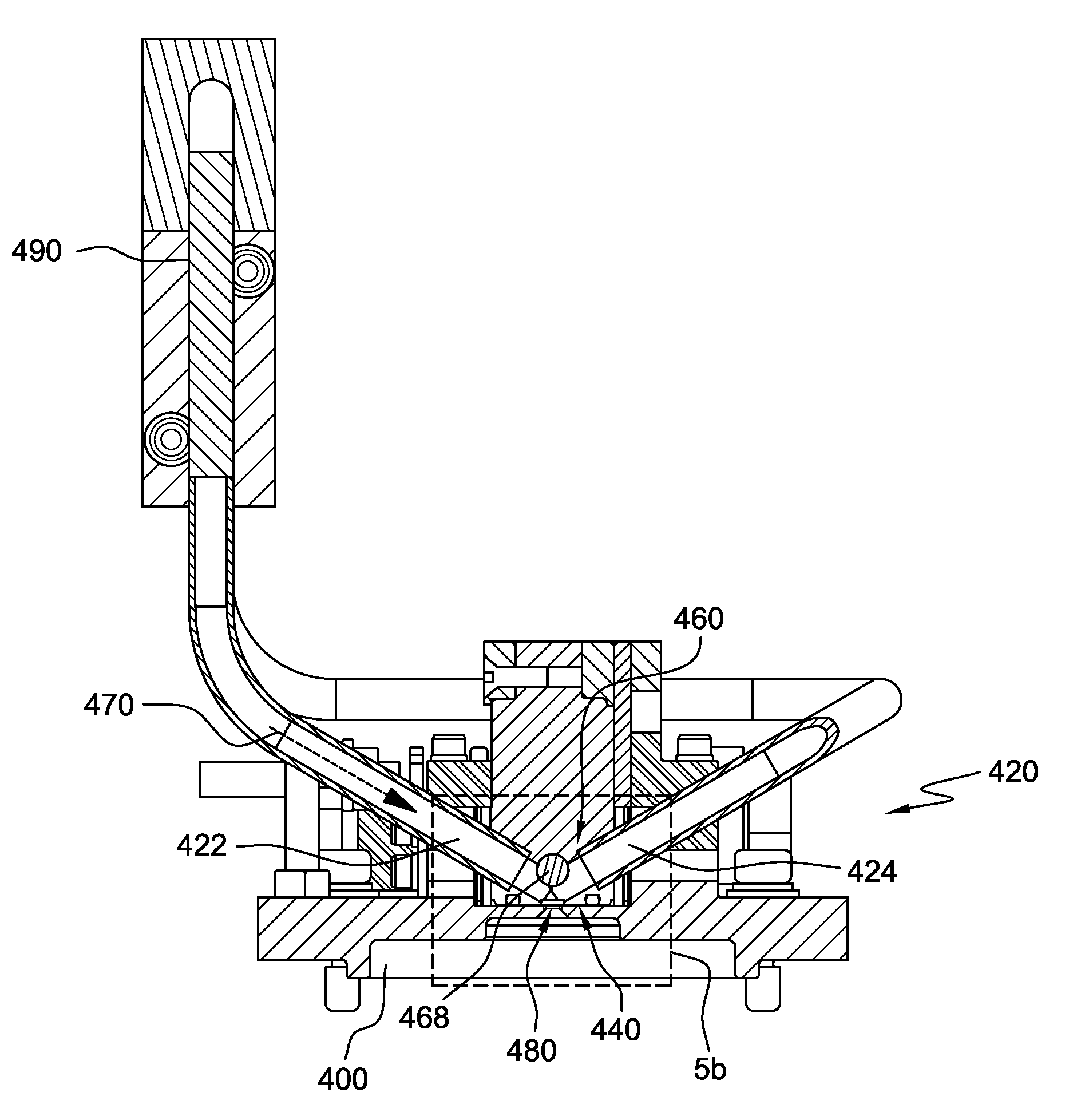

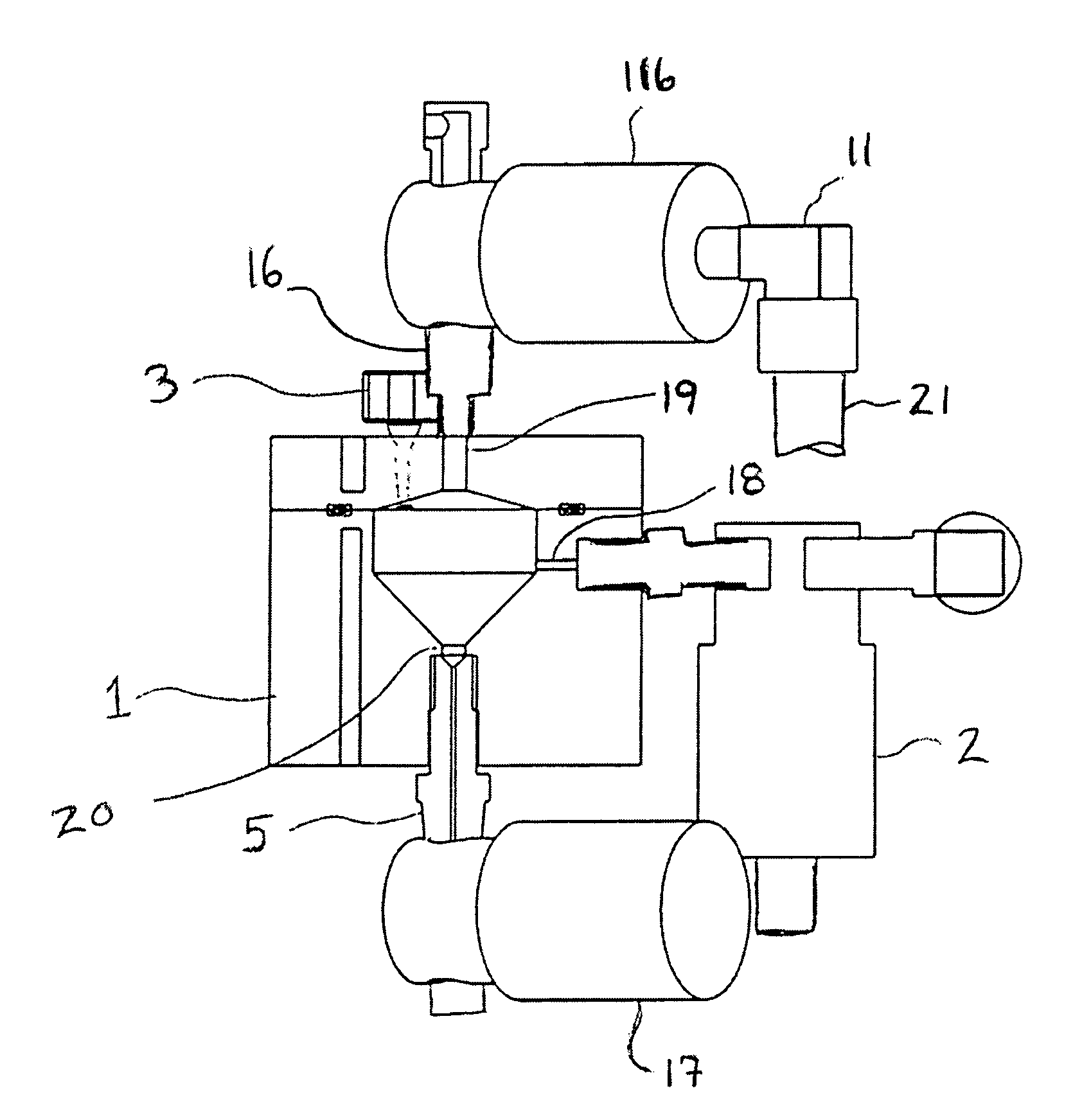

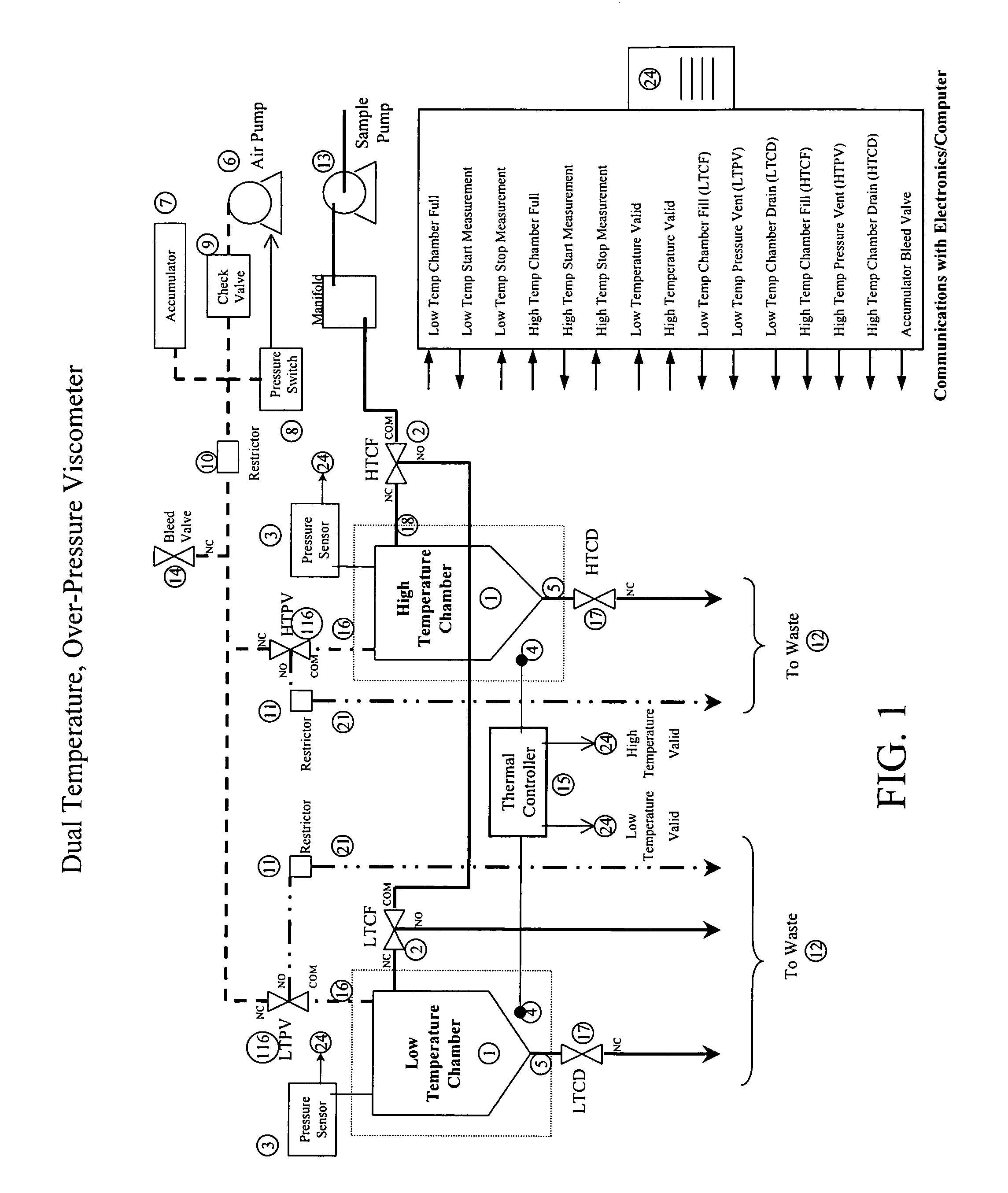

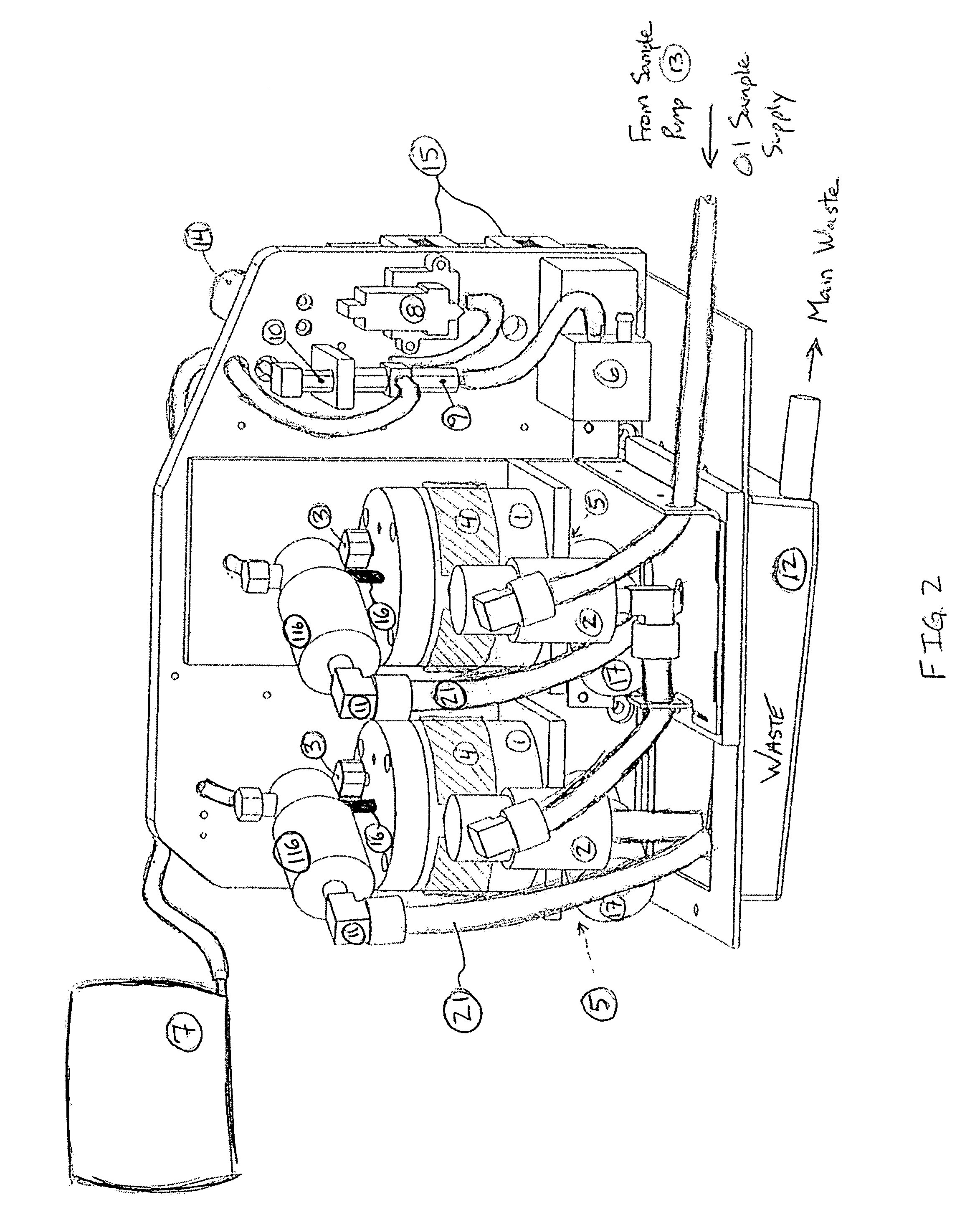

Apparatus and method for measuring viscosity

ActiveUS20060254344A1Reduce and eliminate clogging effect of (particle-laden)Reduced measurement accuracyMaterial testing goodsDirect flow property measurementPetroleum productHigh pressure

An apparatus and methods for analysis of a petroleum product, specifically determining the viscosity of a sample, are disclose. The apparatus includes a sample reservoir for receiving a liquid sample and a pressure regulator for applying hyperbaric pressure to a sample within the reservoir. When pressure is applied to the sample reservoir, the sample is forced through a passageway and a pressure sensor monitors the pressure in the sample reservoir. A drop in the pressure can be used to determine when the reservoir is empty and sample viscosity can be calculated based on the time required to empty the reservoir.

Owner:SPECTRO SCI INC

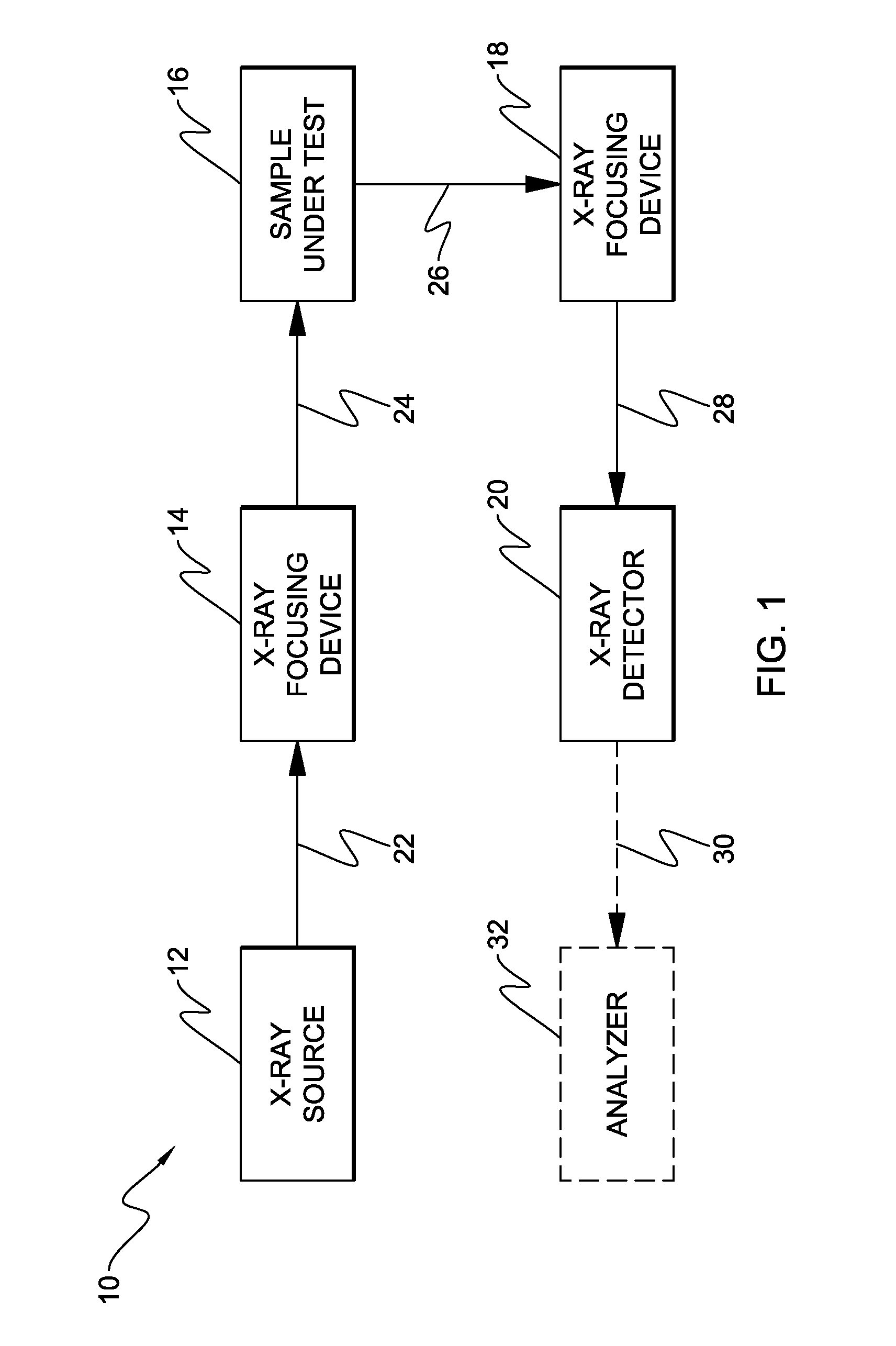

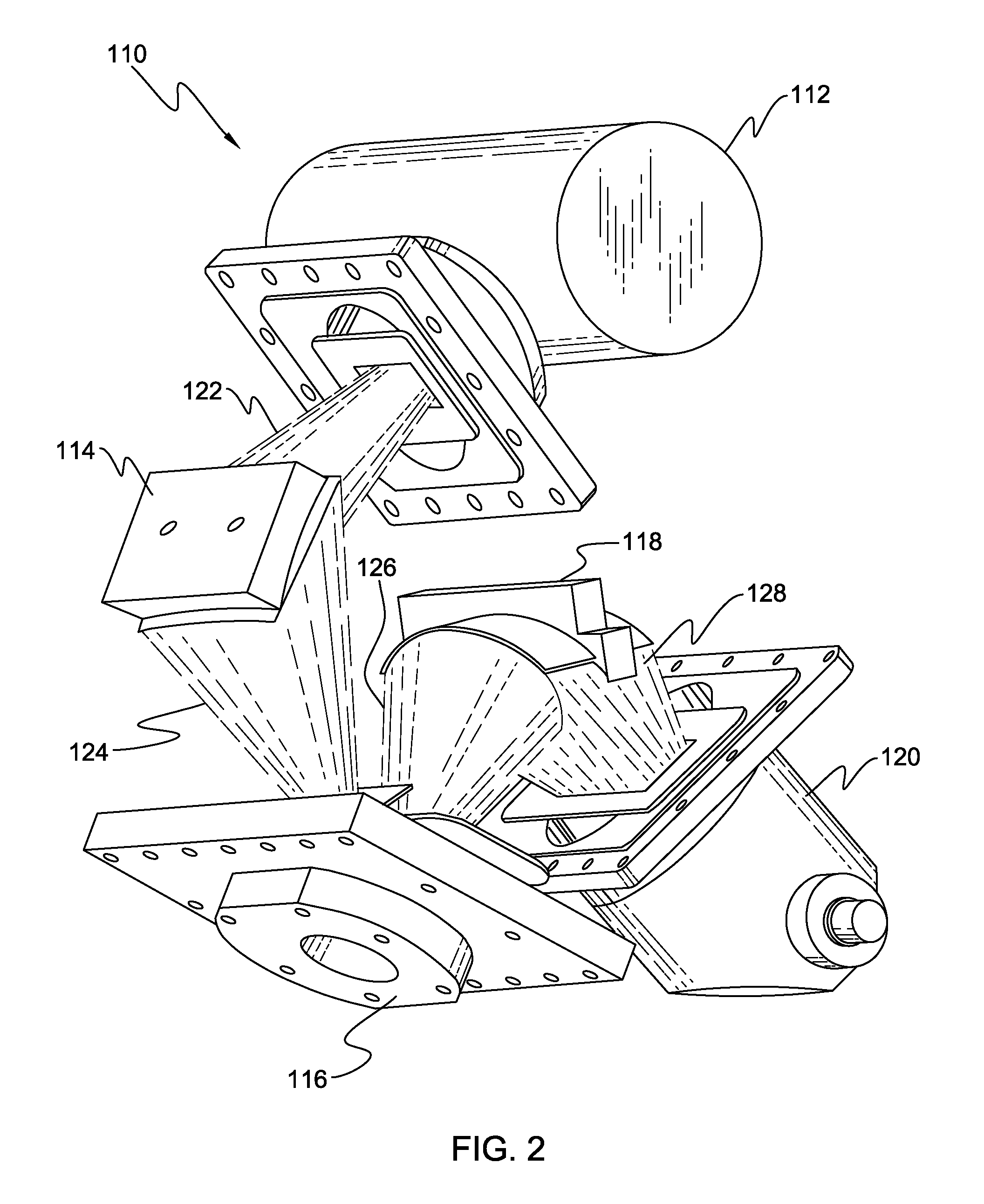

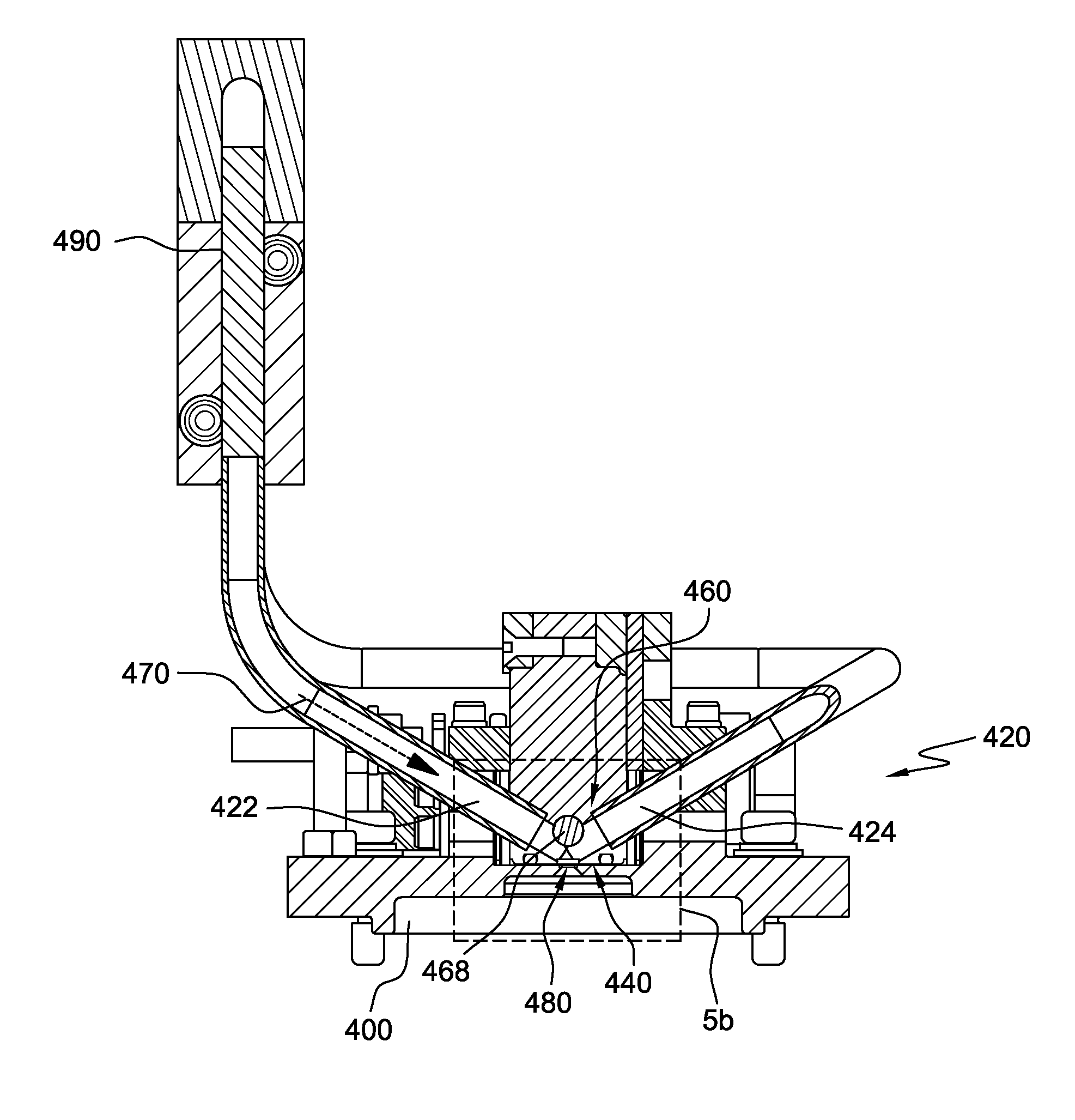

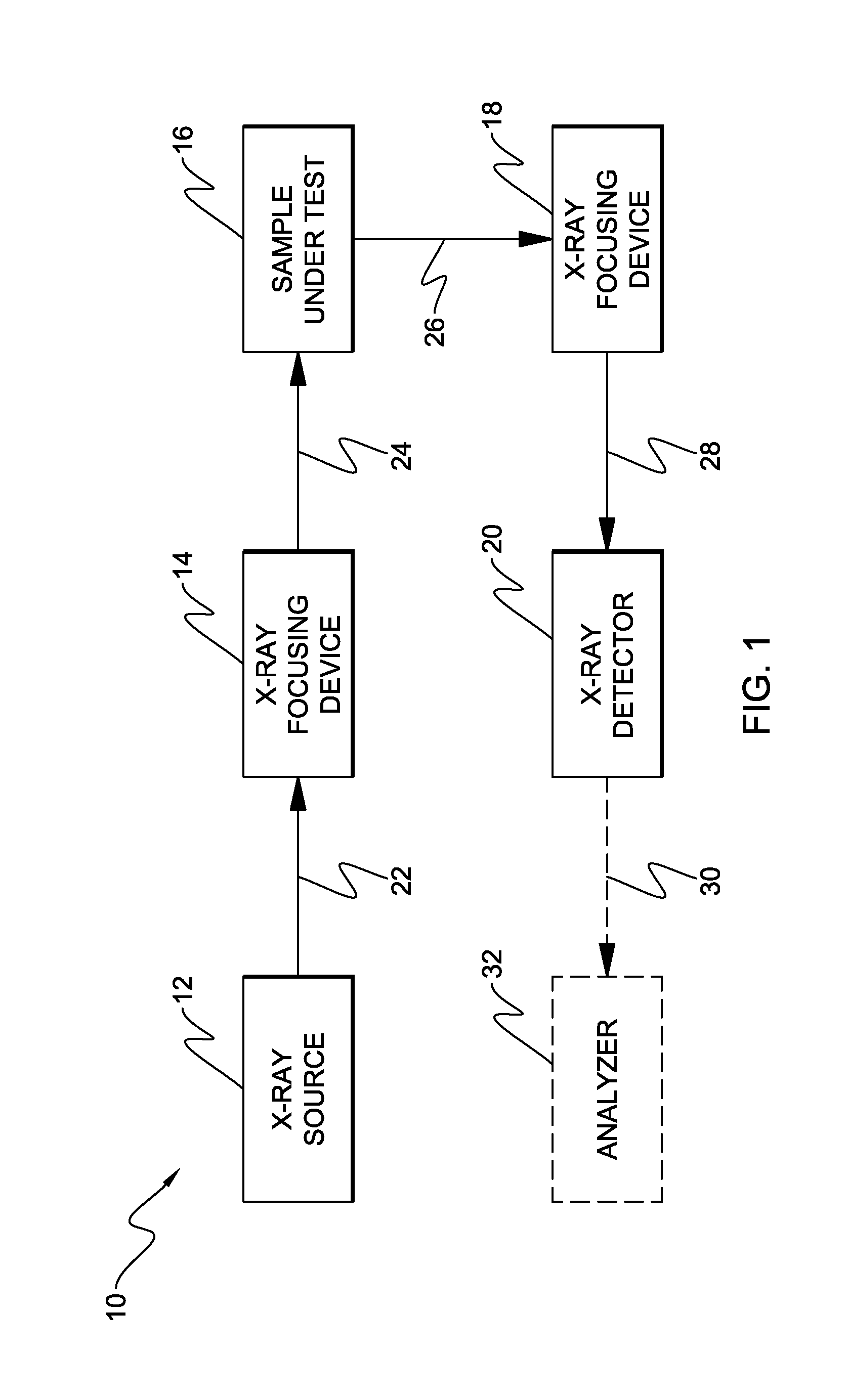

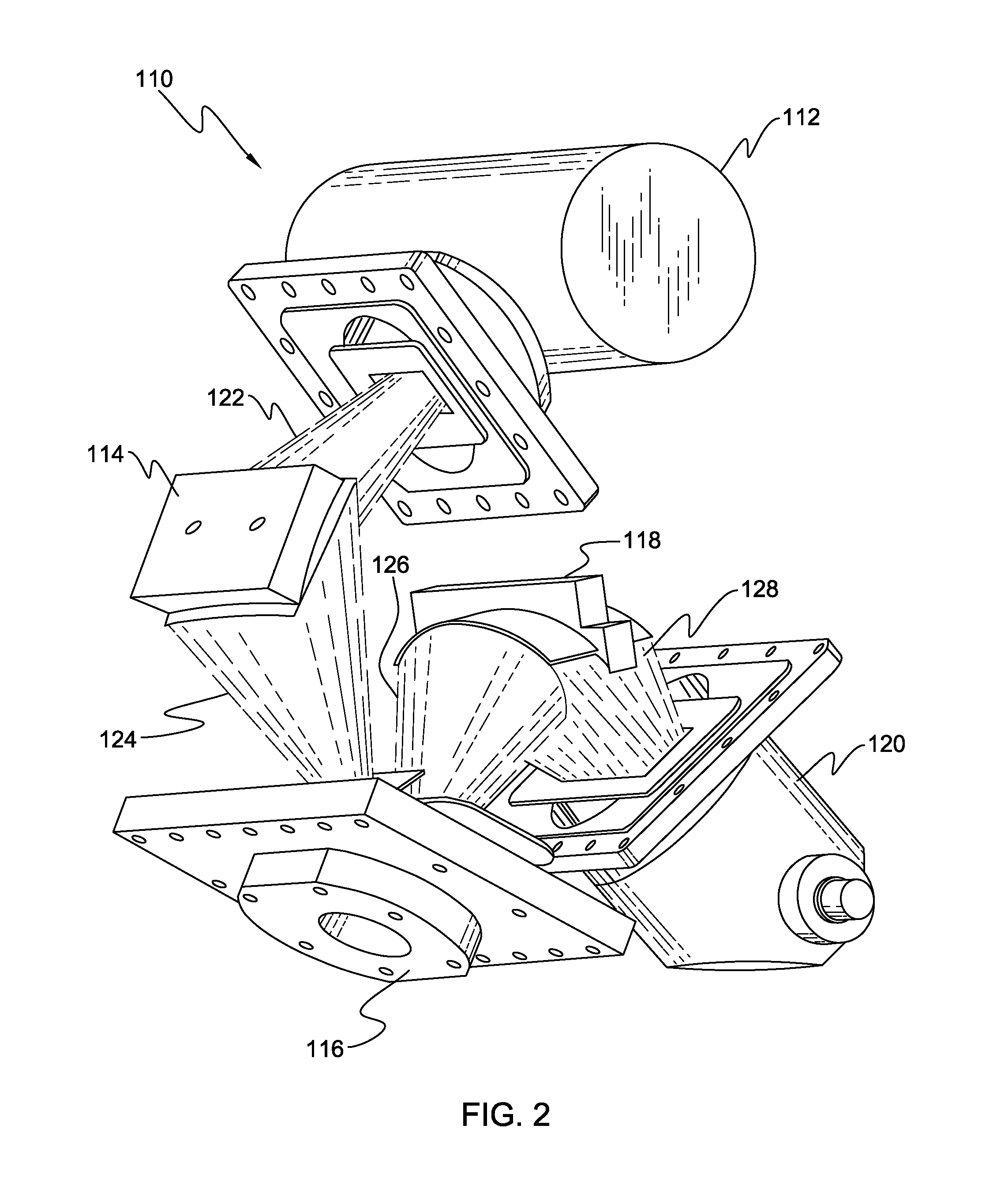

Sample viscosity and flow control for heavy samples, and X-ray analysis applications thereof

ActiveUS9057685B2Overcomes shortcomingHigh trafficX-ray spectral distribution measurementMaterial analysis using wave/particle radiationExcitation beamLight beam

An x-ray analysis system having an x-ray engine with an x-ray source for producing an x-ray excitation beam directed toward an x-ray analysis focal area; a sample chamber for presenting a sample stream to the x-ray analysis focal area, the analysis focal area disposed within a sample analysis area defined within the chamber; an x-ray detection path for collecting secondary x-rays and directing the x-rays toward a detector; an x-ray transparent barrier on a wall of the chamber through which the x-rays pass; and a blocking structure partially blocking the sample analysis area, for creating sample stream turbulence in the sample analysis area and over the barrier. The blocking structure may be disposed asymmetrically about a central axis of the x-ray analysis focal area and / or the sample analysis area; and may be a rounded pin. A heating element may be used to heat the sample stream for improving flow.

Owner:X-RAY OPTICAL SYSTEM INC

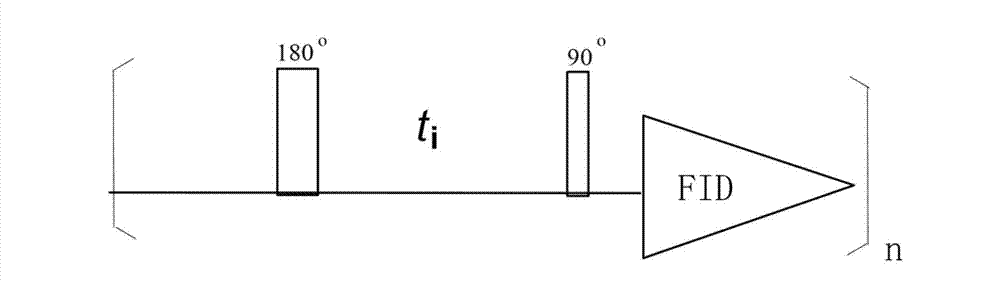

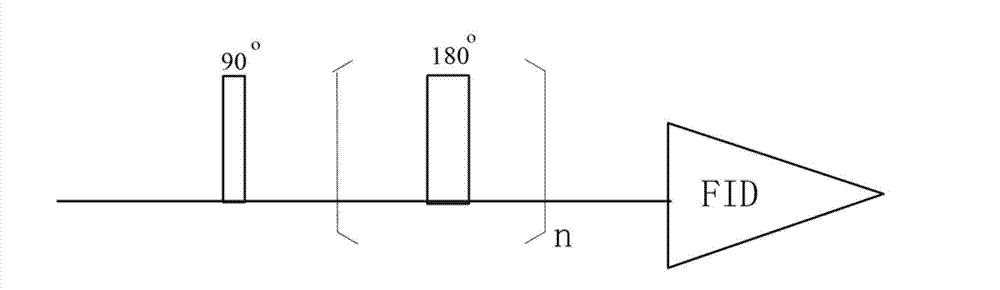

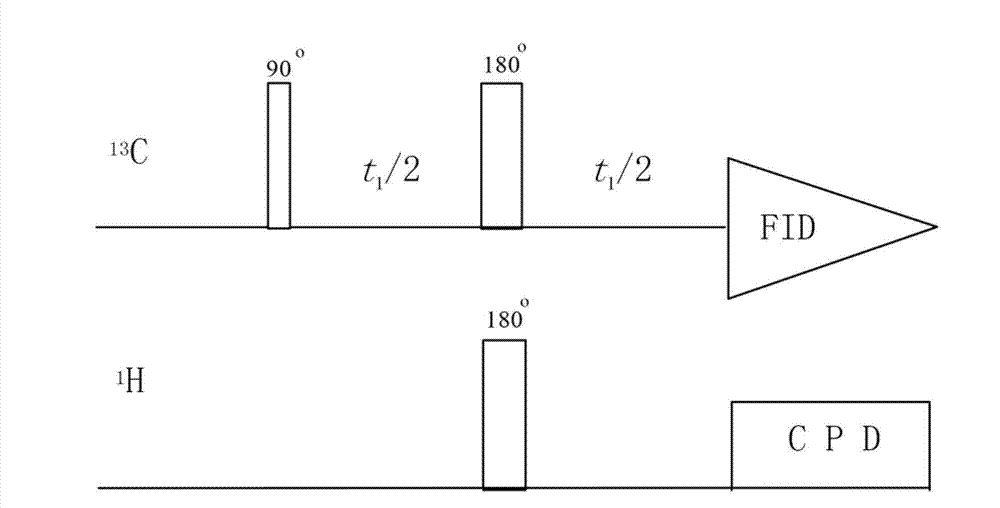

Nuclear-magnetic-resonance-technology-based method for detecting transformer oil ageing state parameters

ActiveCN103091345AGood linear relationshipAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceInversion recovery

The invention discloses a nuclear-magnetic-resonance-technology-based method for detecting transformer oil ageing state parameters. The ageing state parameters comprise oil sample viscosity, oil sample density, oil sample furfural content, oil sample resistance and the like. The method comprises the following steps: performing nuclear magnetic resonance spectrum analysis on a solution gas-containing transformer oil sample and detecting the parameters, wherein the oil sample viscosity eta is measured through the formula shown in the abstract, T1 and T2 respectively refer to longitudinal / transverse relaxation time of the oil sample, T1 is measured by an inversion recovery method, T2 is measured by a CPMG method, the oil sample density and the other parameters are measured by measuring the content of CHn functional groups in the oil sample by utilizing a two-dimensional J-resolved spectroscopy nuclear magnetic resonance analysis method according to a relation model between the content of functional groups and the oil sample density and other parameters; and n in the CHn is equal to 0, 1, 2 and 3. The method has the advantages of few sample quantity, simple and direct sampling process, high analysis speed, high analysis accuracy and the like.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD MAINTENANCE CO +2

Sample viscosity and flow control for heavy samples, and x-ray analysis applications thereof

ActiveUS20130044858A1Overcomes shortcomingEnhanced advantageMaterial analysis using wave/particle radiationX-ray spectral distribution measurementSoft x rayExcitation beam

An x-ray analysis system having an x-ray engine with an x-ray source for producing an x-ray excitation beam directed toward an x-ray analysis focal area; a sample chamber for presenting a sample stream to the x-ray analysis focal area, the analysis focal area disposed within a sample analysis area defined within the chamber; an x-ray detection path for collecting secondary x-rays and directing the x-rays toward a detector; an x-ray transparent barrier on a wall of the chamber through which the x-rays pass; and a blocking structure partially blocking the sample analysis area, for creating sample stream turbulence in the sample analysis area and over the barrier. The blocking structure may be disposed asymmetrically about a central axis of the x-ray analysis focal area and / or the sample analysis area; and may be a rounded pin. A heating element may be used to heat the sample stream for improving flow.

Owner:X-RAY OPTICAL SYSTEM INC

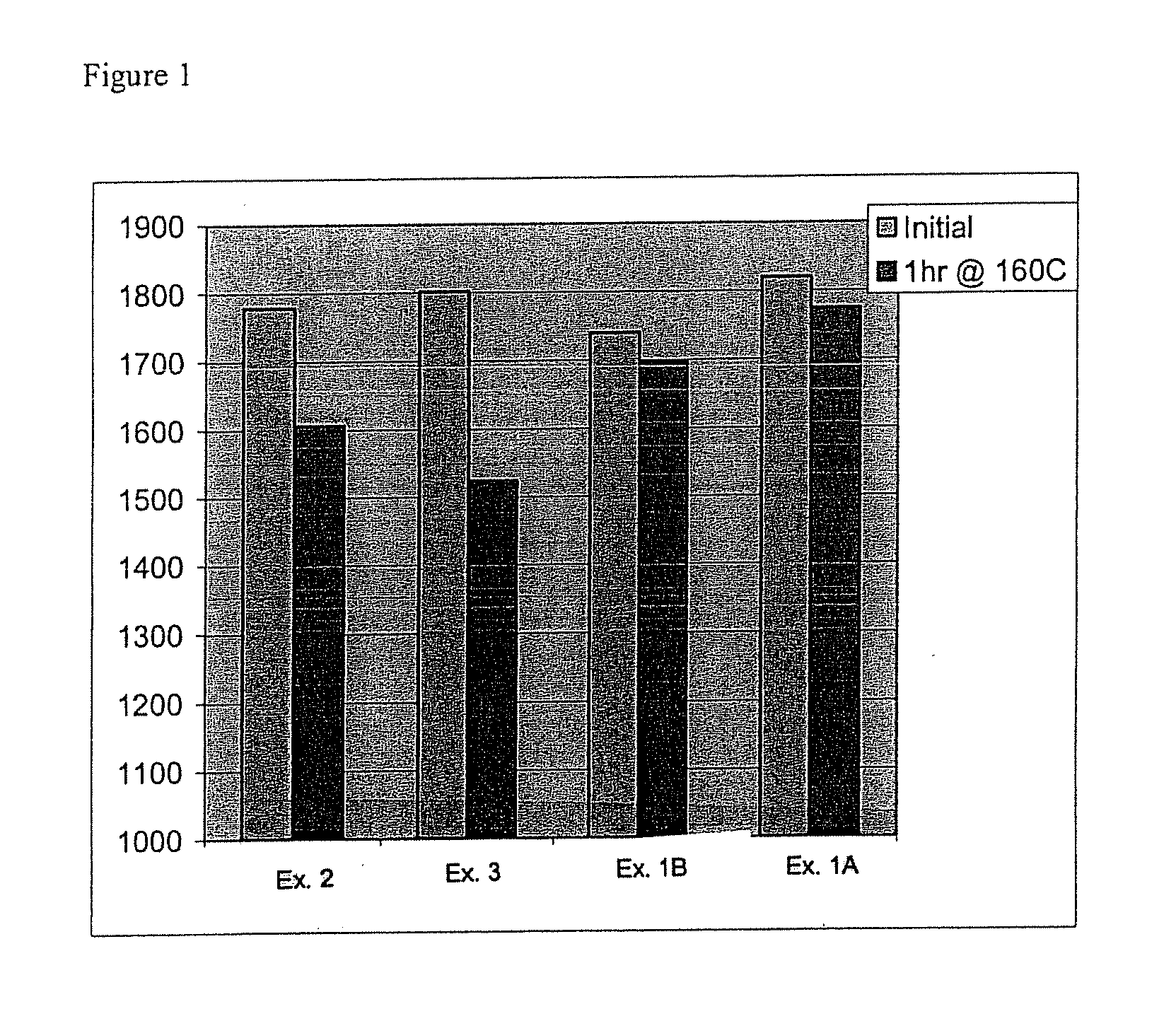

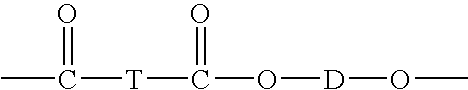

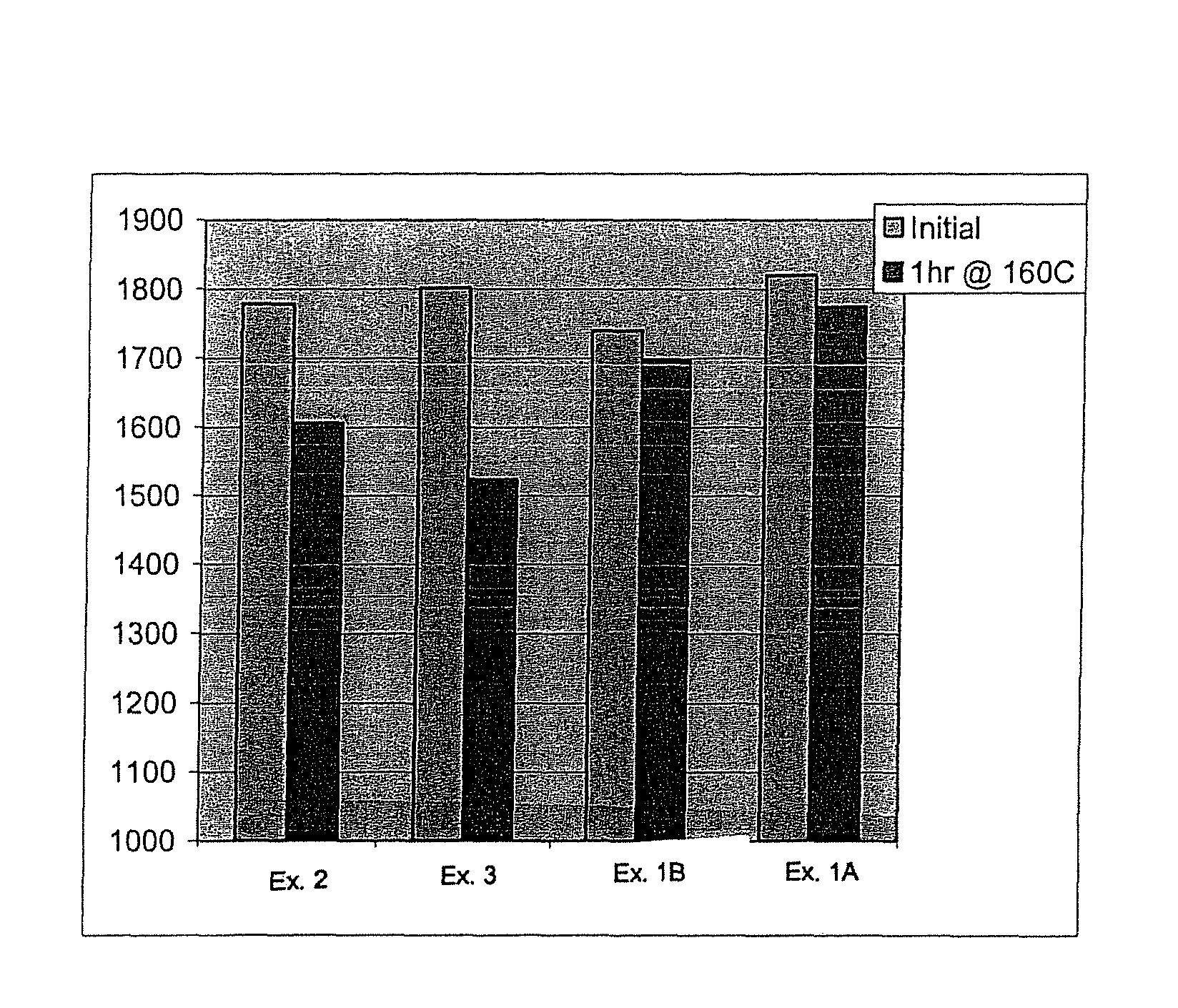

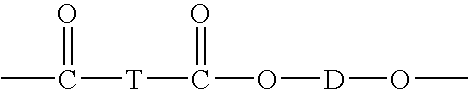

Polyester compositions, methods of manufacture, and uses thereof

A composition is disclosed, comprising, based on the total weight of the composition, a combination of from 44 to 80 weight percent of a thermoplastic poly(butylene terephthalate); from 20 to 50 weight percent of a thermoplastic poly(ethylene terephthalate) having an intrinsic viscosity of 0.5 to 0.8 deciliters per gram, measured in a 60:40 by weight phenol / 1,1,2,2-tetrachloroethane mixture at 23° C. using a relative viscometer operating with a closed loop system, which measures the solvent and sample viscosity simultaneously; from 5 to less than 20 weight percent of a talc filler having an average largest dimension of less than 0.9 micrometers, a median particle size of less than 0.9 micrometers, or both; and from 0.1 to 0.5 weight percent of a mold release agent. The compositions are useful in the manufacture of lighting articles, which can be directly metallized without the inclusion of a base coat.

Owner:SABIC GLOBAL TECH BV

Apparatus and method for measuring viscosity

ActiveUS7237431B2Reduce and eliminate clogging effect of (particle-laden)Reduced measurement accuracyMaterial analysis by optical meansMaterial testing goodsPetroleum productHigh pressure

An apparatus and methods for analysis of a petroleum product, specifically determining the viscosity of a sample, are disclose. The apparatus includes a sample reservoir for receiving a liquid sample and a pressure regulator for applying hyperbaric pressure to a sample within the reservoir. When pressure is applied to the sample reservoir, the sample is forced through a passageway and a pressure sensor monitors the pressure in the sample reservoir. A drop in the pressure can be used to determine when the reservoir is empty and sample viscosity can be calculated based on the time required to empty the reservoir.

Owner:SPECTRO SCI INC

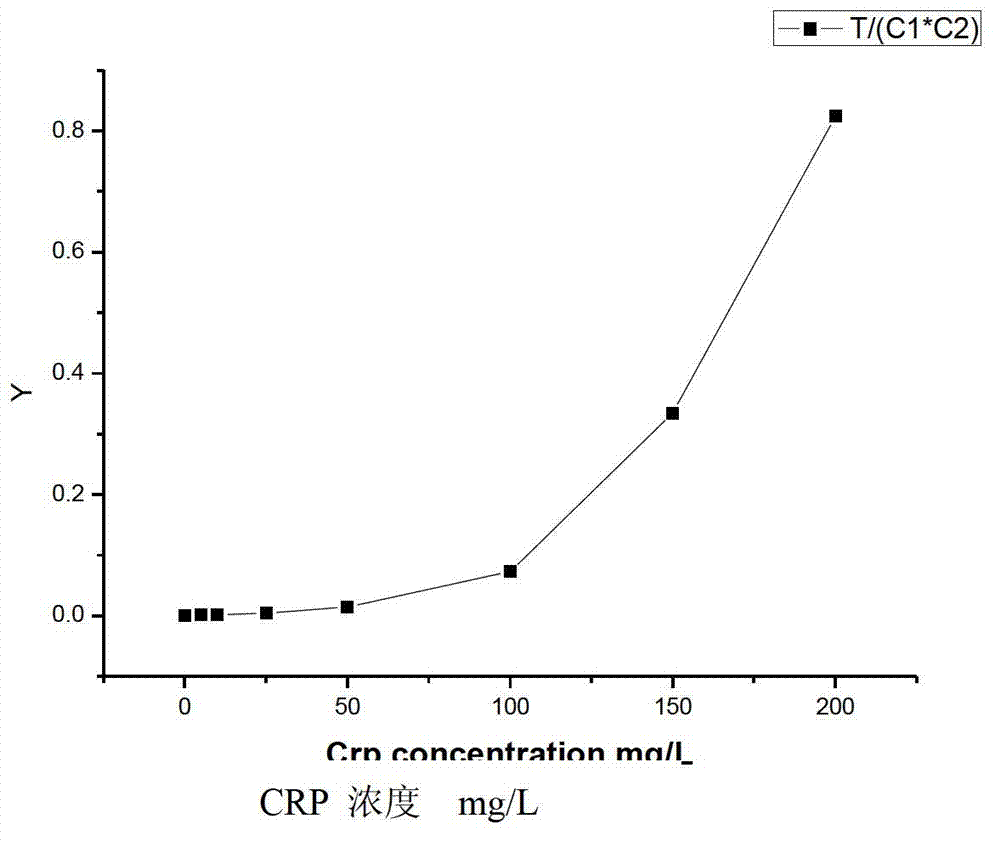

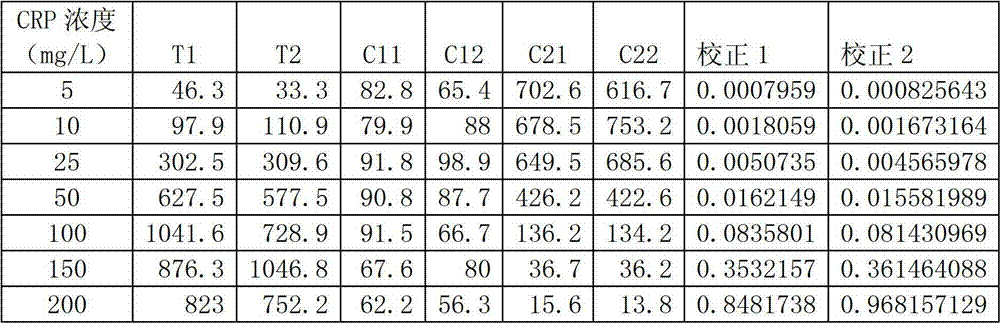

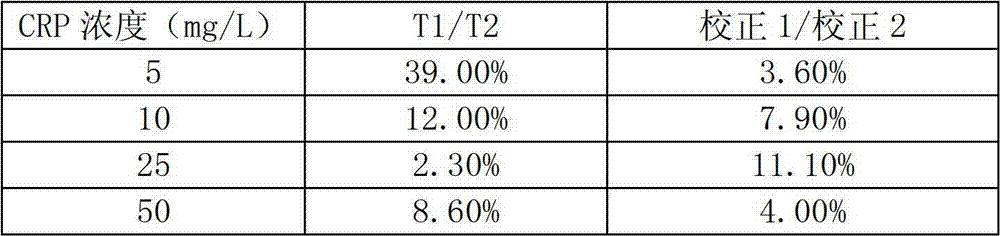

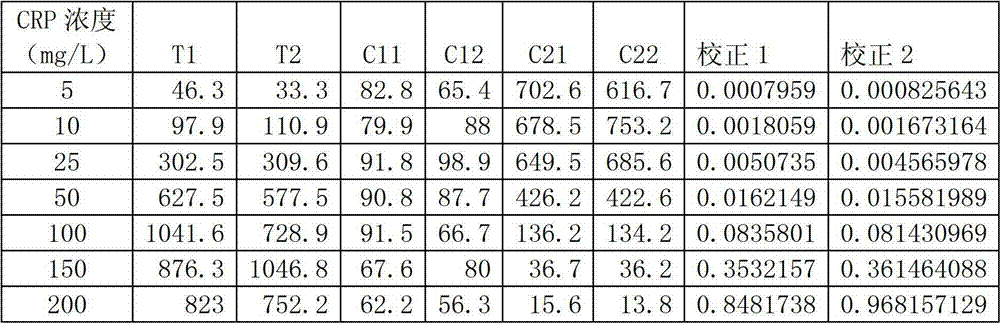

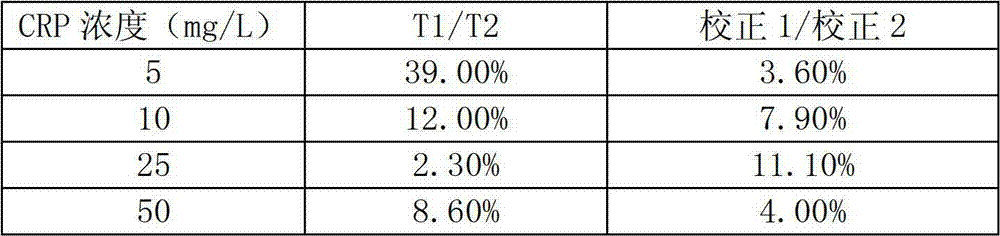

Colloidal gold immunofiltration quantitive detection method and reagent kit

The invention relates to clinical immunodiagnosis reagents and preparation methods thereof, and discloses a colloidal gold immunofiltration quantitive detection reagent kit and a method for detecting antigens and antibodies by colloidal gold immunofiltration quantitive detection. One or two quality control lines or points which contain known to-be-detected substances are added on the colloidal gold immunofiltration quantitive detection reagent kit. In one reaction, change of color developing degree of detection lines (points) is relevant with change of color developing degree of the quality control lines (points) significantly, deviation of the detection lines (points) can be corrected by the quality control lines (points), and thus, variation caused by deviation of raw materials (nitrocellulose membranes, water absorbent pads), sample viscosity, temperature and sample adding quantity and the like can be overcome effectively.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Treatment method for analytical ferrograph ferrogram-making oil sample

InactiveCN103575573ANo accumulationEasy to observe clearlyPreparing sample for investigationOrganic solventMicrometer

The invention discloses a treatment method for an analytical ferrograph ferrogram-making oil sample. The method comprises: firstly subjecting a collected oil sample to heating and oscillation to make abrasive particles suspend uniformly; detecting the content of iron in the oil sample, setting an oil sample abrasive particle concentration dilution ratio respectively according to the iron content, and adopting liquid paraffin as a concentration diluting solvent; employing a tetrachloroethylene organic solvent to dilute the oil sample viscosity, keeping the volume ratio at 3:1; subjecting the oil sample to ferrogram-making, and then subjecting the abrasive particles to monolayer deposition on a substrate, keeping the abrasive particle coverage within the range of 10%-30%, depositing ferromagnetic abrasive particles greater than 5 micrometers in the entrance region of a ferrogram, and arranging the abrasive particles in a chain along a magnetic line direction. The abrasive particles on the ferrogram are free of stacking phenomenon, and no residual oil trace is left on the ferrogram, thus facilitating clear observation of a ferroscope. The method provided by the invention determines and established an oil sample dilution ratio standard, and under the premise of ensuring the abrasive particle accuracy reflected by the ferrogram, enhances the ferrogram-making efficiency of an analytical ferrograph, and improves the accuracy of equipment diagnosis.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

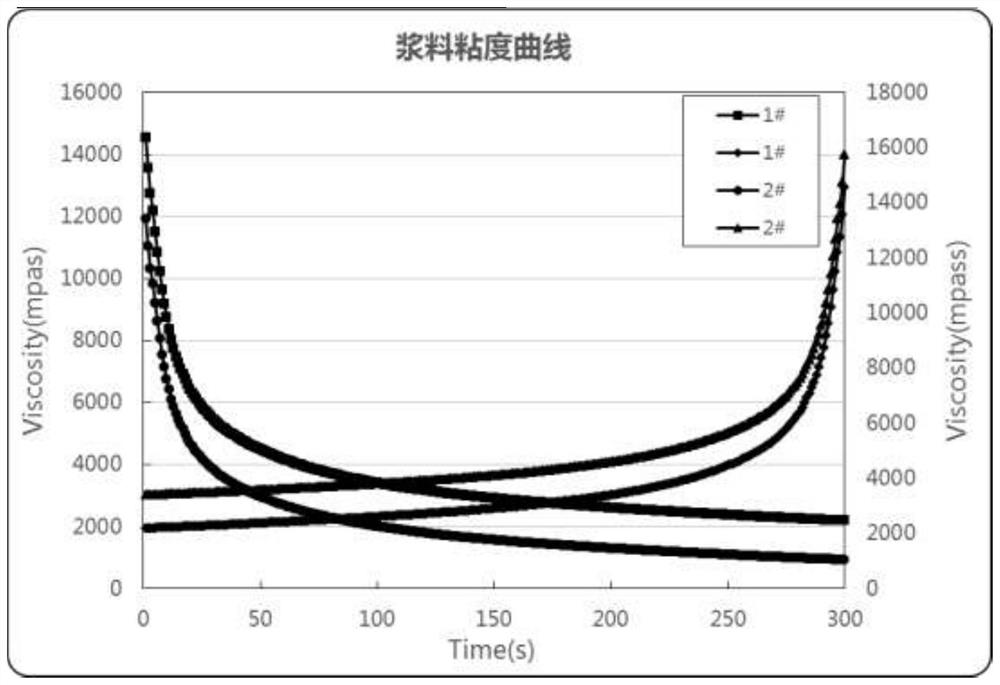

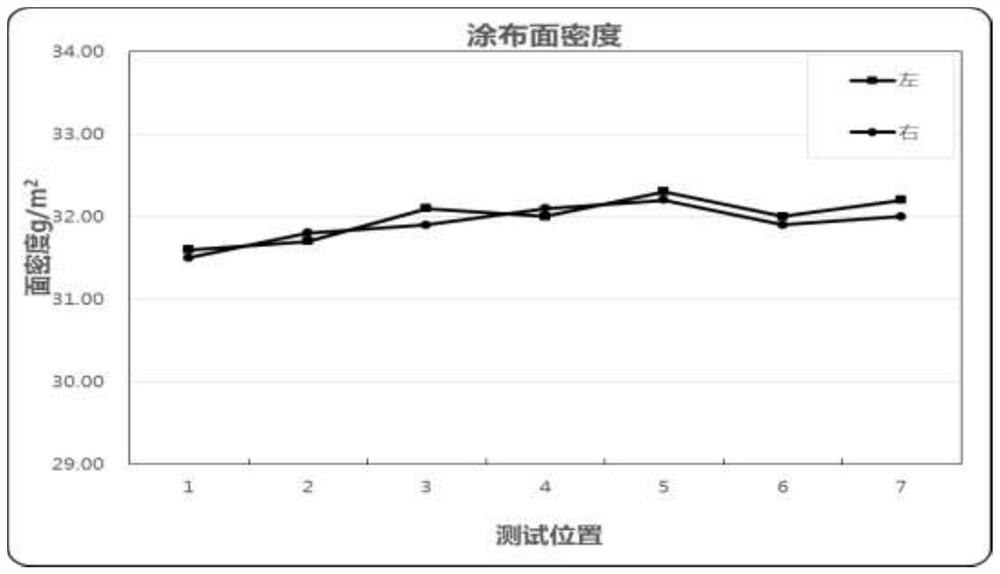

Method for detecting stability and viscosity of battery slurry

InactiveCN111624136AEvaluation StabilityEvaluation viscosityFlow propertiesThermodynamicsEngineering

The invention discloses a method for detecting the stability and viscosity of battery slurry, which comprises the following steps: S1, respectively sampling from the upper layer and the lower layer ofthe battery slurry, and marking as an upper-layer sample and a lower-layer sample; S2, respectively carrying out twice test scanning on the upper-layer sample and the lower-layer sample by using a rheometer to obtain four rheological curves; S3, analyzing the coincidence of the four rheological curves, wherein when the coincidence of the four curves is poor, it is determined that the stability ofthe battery slurry is poor, and when the coincidence of the four curves is excellent, it is determined that the stability of the battery slurry is good, and calculating the average value of the viscosity of the sample detected for four times to obtain the viscosity of the battery slurry. The method is simple to operate, and the stability and viscosity value of the battery slurry can be accuratelyevaluated.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

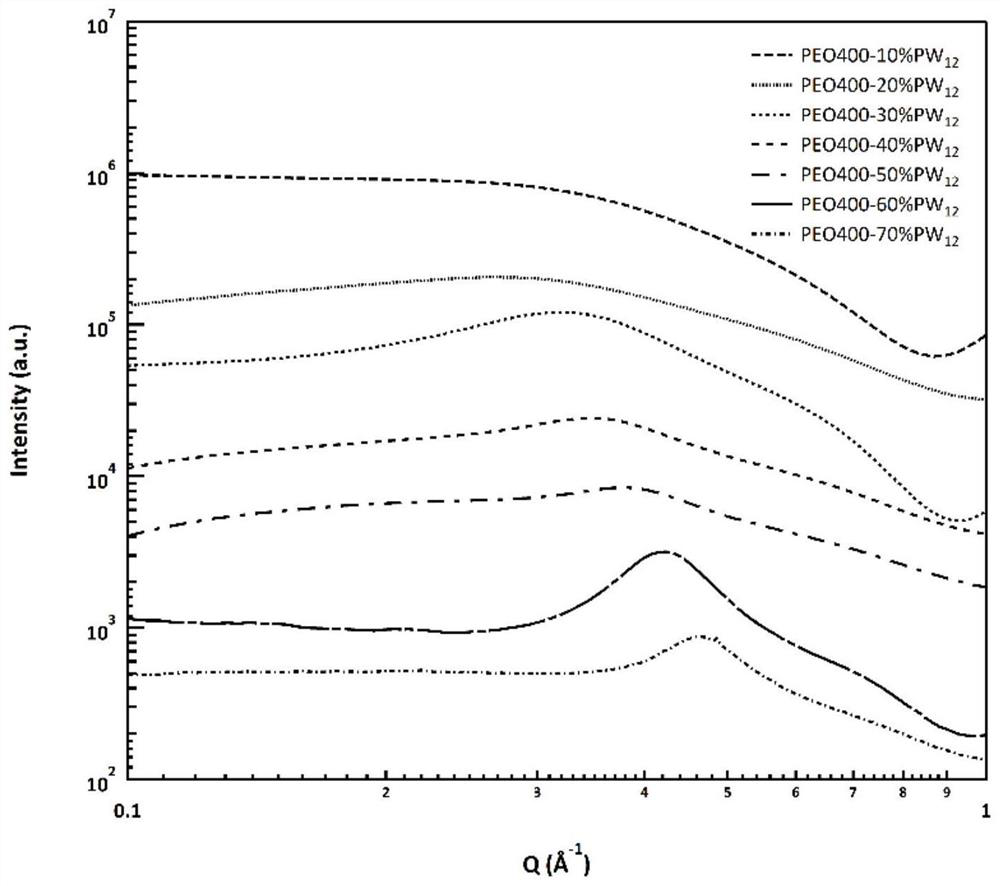

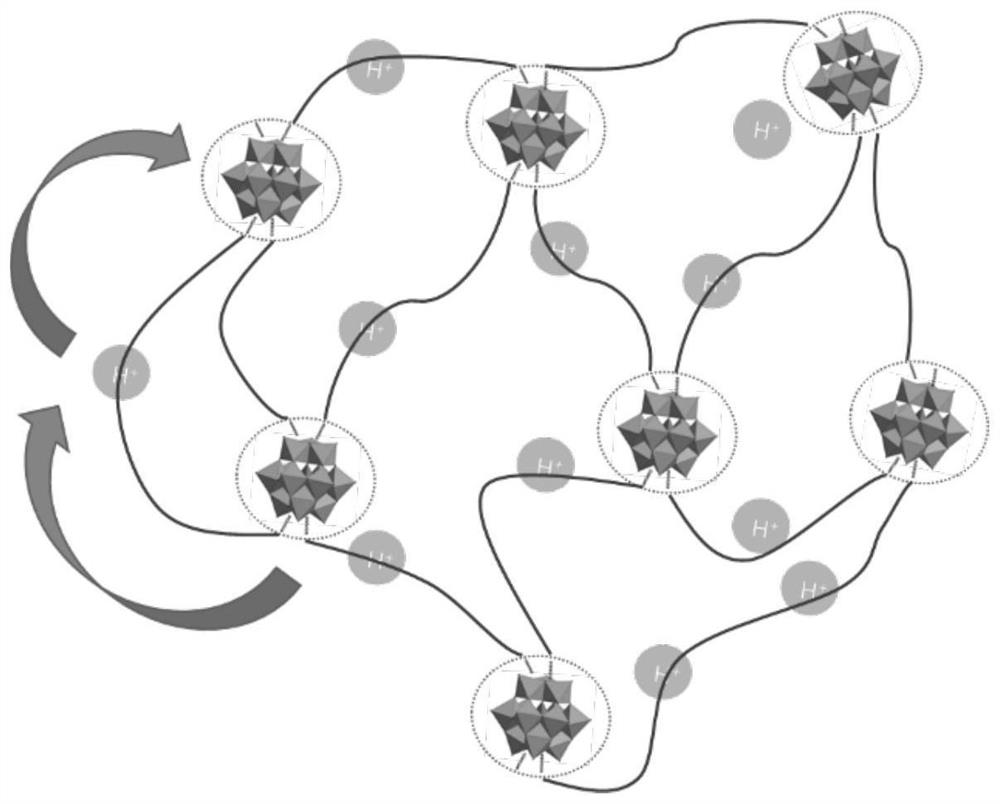

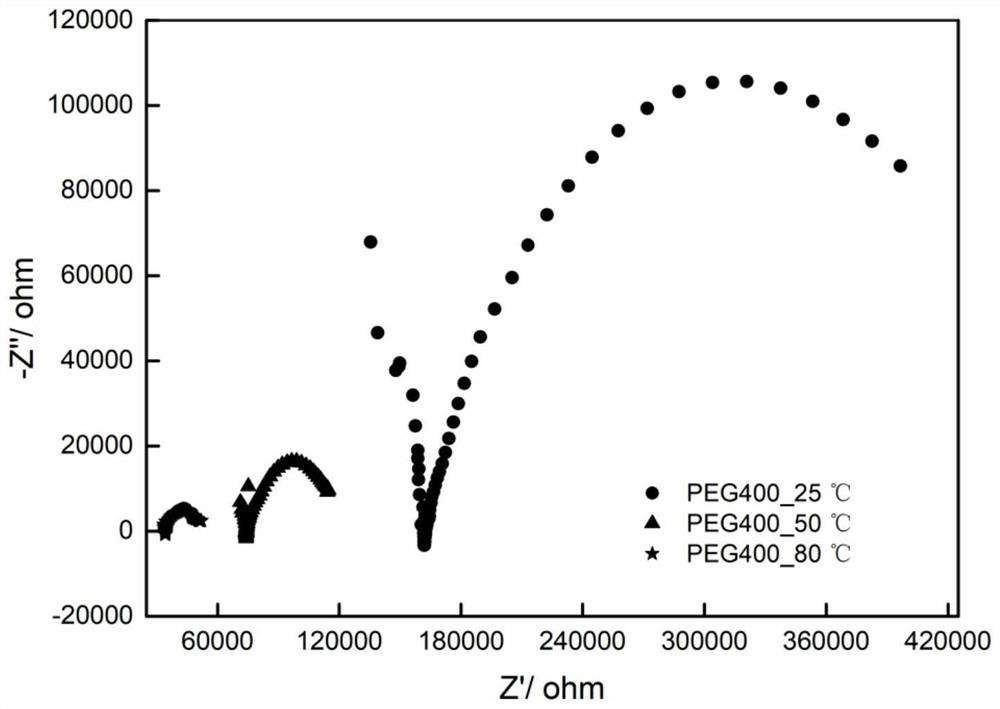

Polyacid-based electrolyte conductor material as well as preparation method and application thereof

PendingCN112151842AHigh proton conduction efficiencyEasy to prepareHybrid capacitor electrolytesSecondary cellsElectrical conductorPhysical chemistry

The invention discloses a polyacid-based electrolyte conductor material as well as a preparation method and application thereof, and particularly discloses two preparation methods, namely a solid-state melting method and a solvent method. According to the polyacid-based electrolyte conductor material prepared by the invention, polyacid and a polymer form a three-dimensional network through hydrogen bond interaction, so effective transfer of protons is realized. When the polyacid mass ratio is 70%, the conductivity of the conductor material can reach 1.01*10 <-2> Scm < 1 > (-80 DEG C). In the aspect of mechanical properties, viscosity of the sample is 273 Pa.s, and safety of the sample as an electrolyte is guaranteed. Due to the shearing thinning behavior, the polyacid-based electrolyte conductor material has good processability.

Owner:SOUTH CHINA UNIV OF TECH

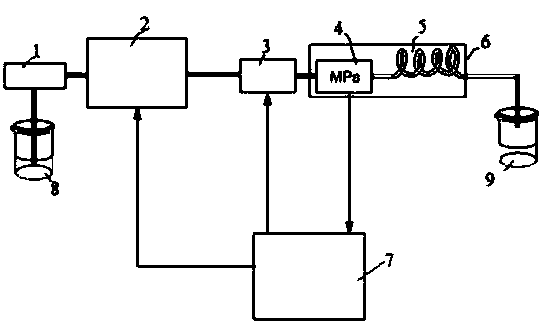

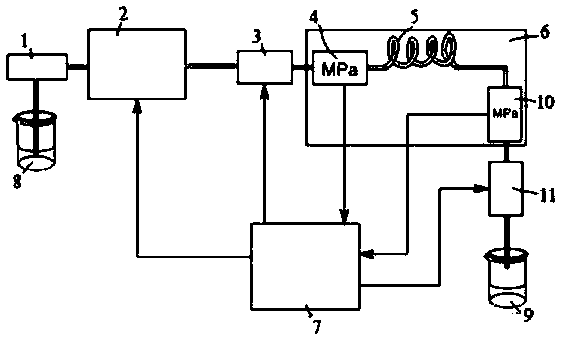

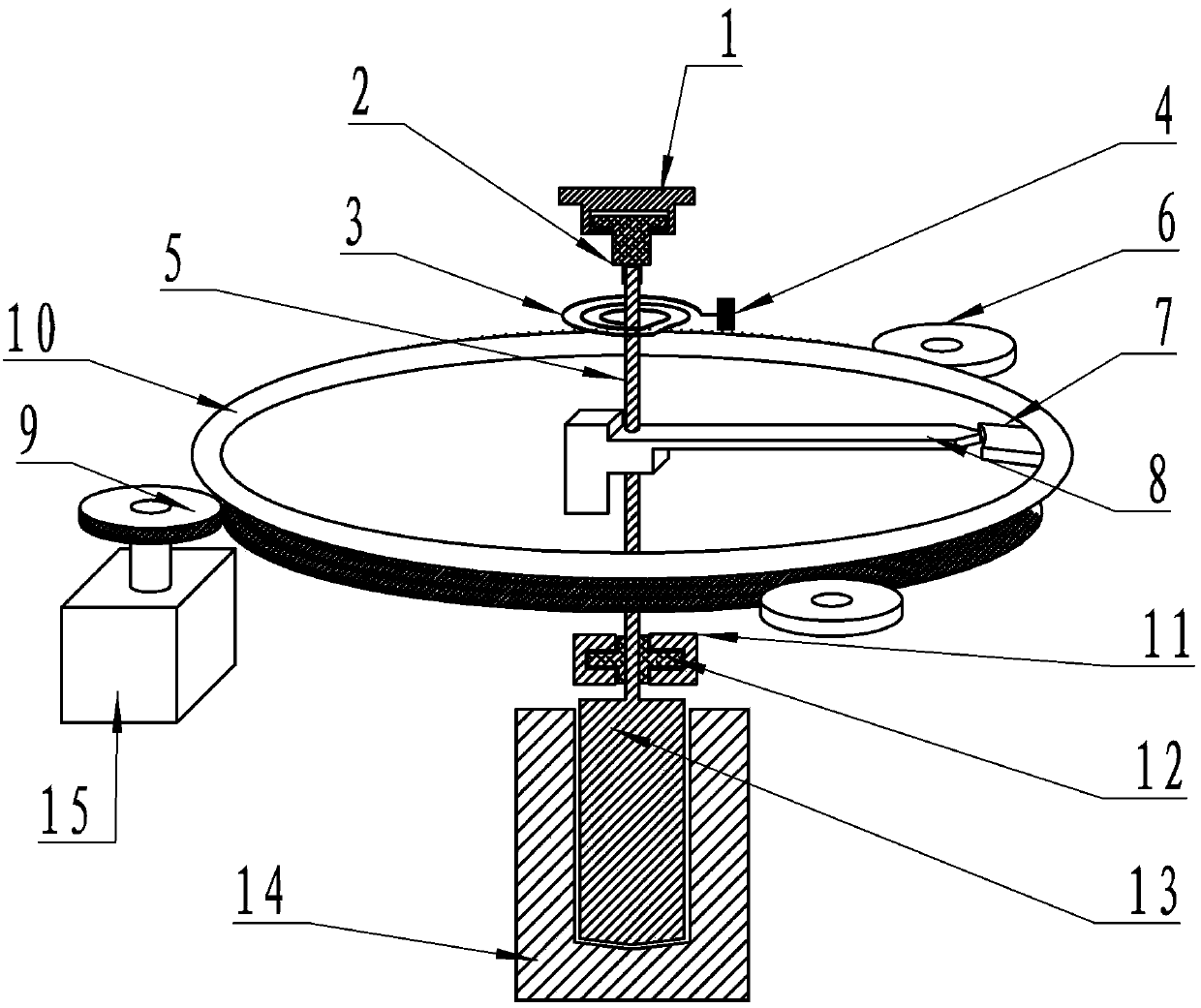

Method for measuring liquid viscosity in capillary tube based on micro volume sample measurement

ActiveCN109342271AReduce consumptionExpand the scope of testingDirect flow property measurementMultiple injectionLiquid viscosity

The invention discloses a method for measuring the liquid viscosity in a capillary tube based on micro volume sample measurement, comprising the following steps of: filling the flow path with the flowing medium and then introducing the sample fluid, which is pushed by the flowing medium through the capillary tube; setting the volume V of the injection liquid to be larger than the volume Vc of thecapillary tube when the viscosity of the sample fluid is small or the sample fluid is compressed under high pressure so that the reduced volume thereof is negligible; and performing multiple injections and ensuring that the volume V of each injection liquid is smaller than the volume Vc of the capillary tube when the viscosity of the sample fluid is large and the sample fluid is compressed under high pressure but the reduced volume is not negligible. According to the method for measuring the liquid viscosity in a capillary tube based on micro volume sample measurement, the consumption of the sample is reduced by the setting of the flowing medium; the viscosity of the sample can be calculated without standard sample calibration, which also contribute to the consumption reduction of the sample; the sample consumption of the invention is small, thereby facilitating the testing of the micro volume sample and broadening the test range of the sample; and the method is suitable for the viscosity determination of non-Newtonian fluids and is excellent in practicability.

Owner:成都珂睿科技有限公司

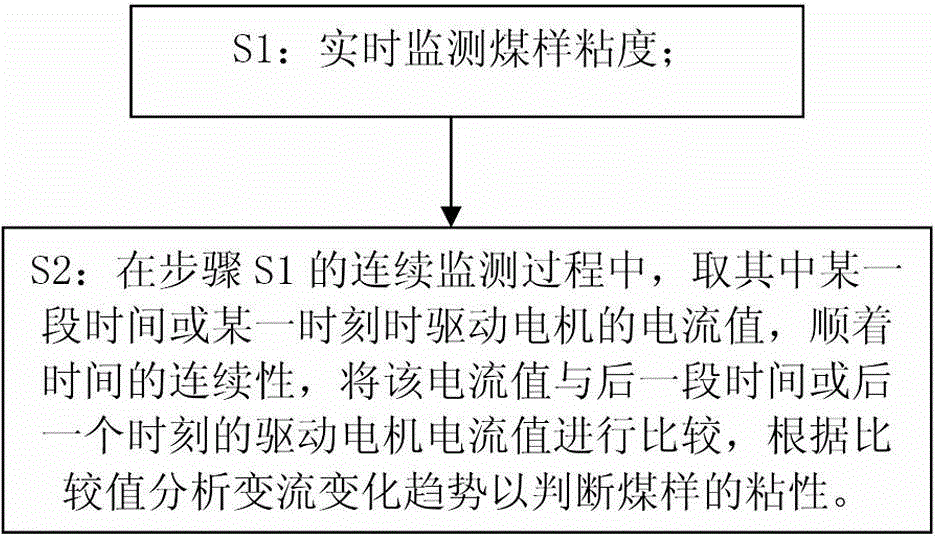

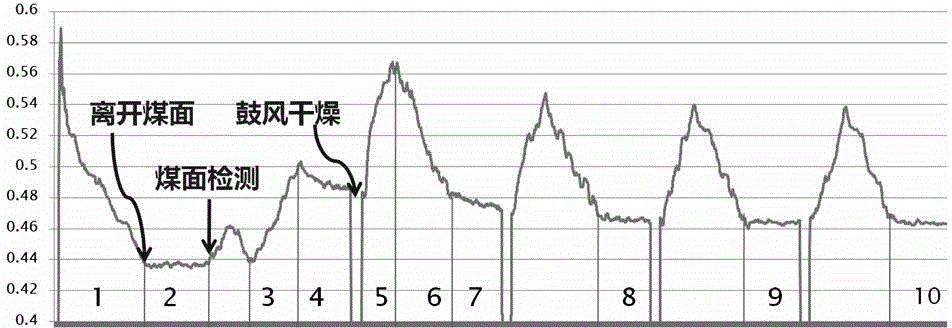

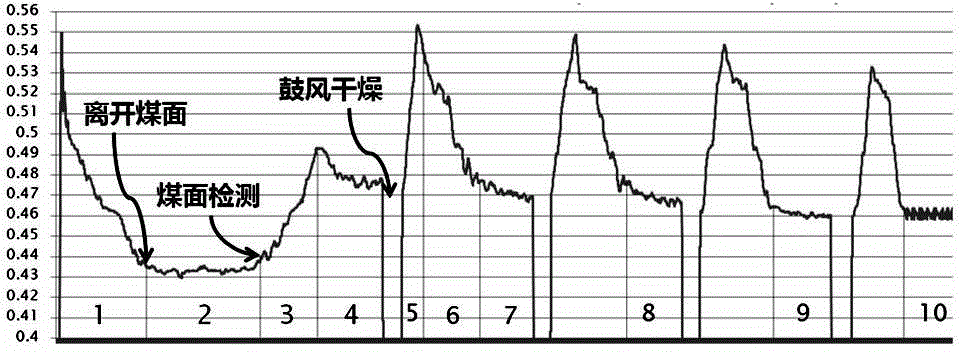

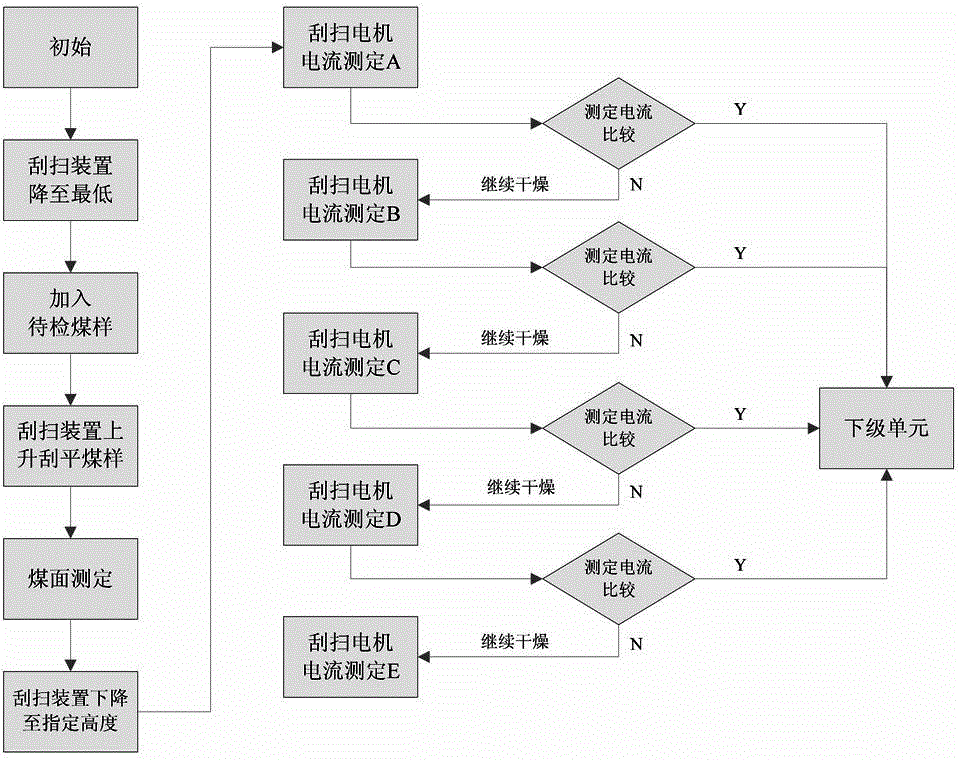

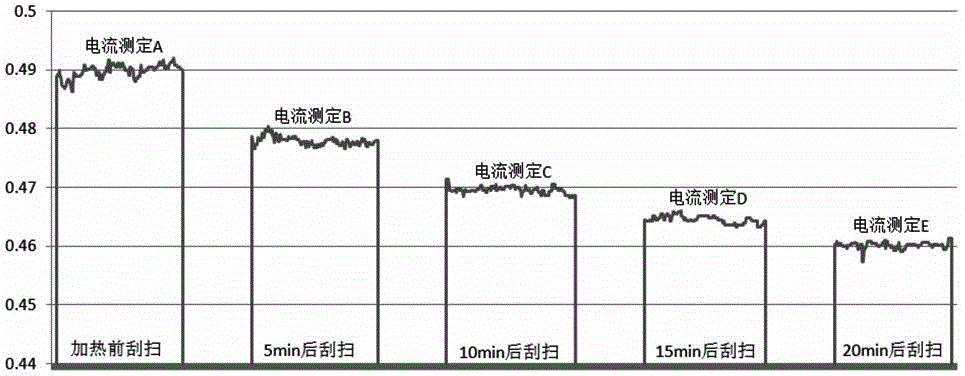

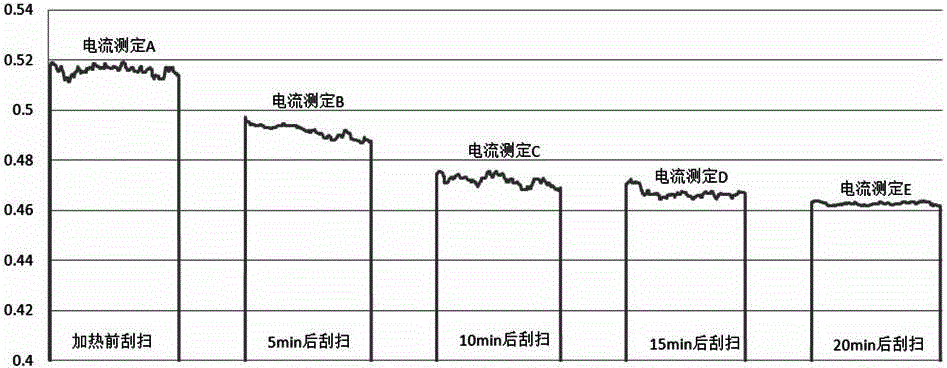

Coal sample viscosity distinguishing method used for coal sample collection and preparation integration

ActiveCN104914009AGuaranteed sample representativenessMeet the precision requirementsFlow propertiesEngineeringDrive motor

The invention discloses a coal sample viscosity distinguishing method used for coal sample collection and preparation integration. The method comprises the following steps: S1. monitoring the coal sample viscosity in real time: during normal operation of collection and preparation integrated coal sample detection equipment, monitoring the current value of a driving motor in a rotary wiping device in the integrated coal sample detection equipment in real time when coal samples pass through a rotary wiping position; S2. in the continuous monitoring process in the step S1, taking the current value of the driving motor at a certain period of time or at a given time, comparing the current value with the current value of the driving motor at a later certain period of time or at a later given time along with the continuity of time, and analyzing the variation trend of alternating current according to the comparison value to judge the coal sample viscosity. The method has the advantages of simple principle, extreme simplicity and convenience in operation, high precision, and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

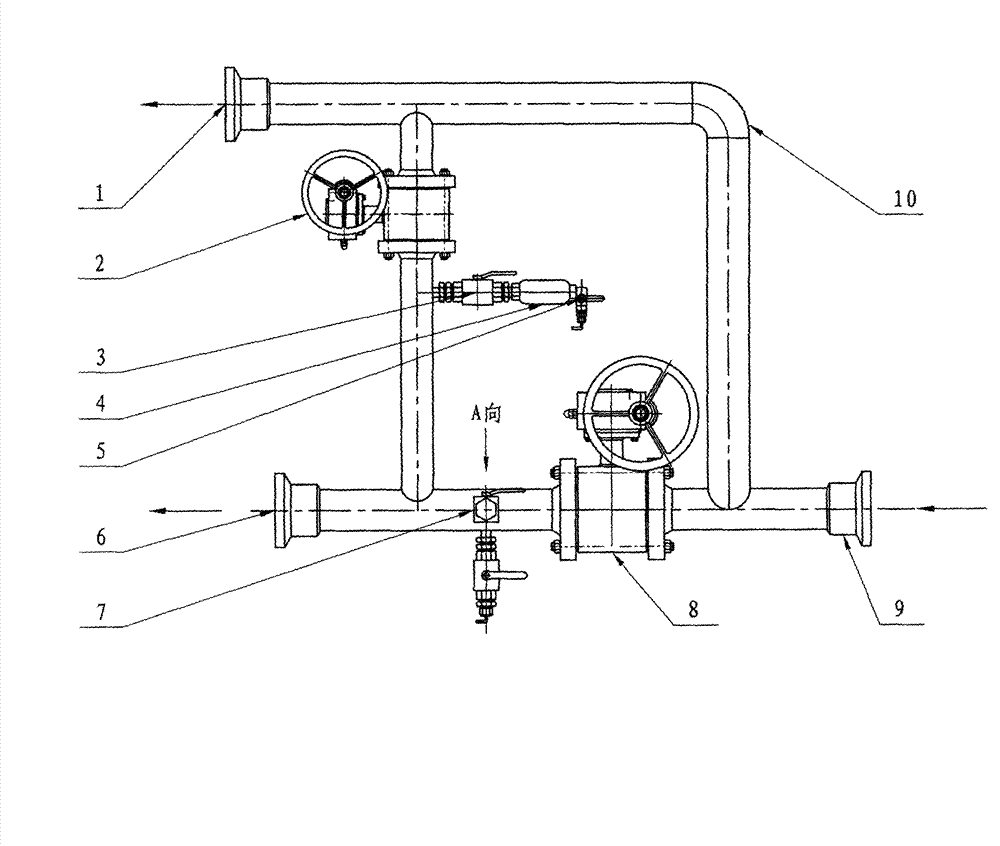

Bypass tertiary oil recovery online sampling device

InactiveCN103195419AReduce shear rateGuaranteed accuracyBorehole/well accessoriesEconomic productionEngineering

A bypass tertiary oil recovery online sampling device comprises a connector I, a worm gear ball valve I, a pressure relief valve, a pressure relief cavity, an emptying valve, a connector II, a sampling valve, a worm gear ball valve II, a connector III and an elbow. The bypass tertiary oil recovery online sampling device is characterized in that interception and sampling of a solution are achieved by controlling opening and closing of valves and is a double-connector direct-connection parallel-pipeline novel online anti-theft spraying-preventing sampling device developed and produced for oil field tertiary oil recovery process. By adopting a low-shearing ball valve, the diameter of an inlet / outlet of polymers is increased, sampling viscosity retention rate is high, and the accuracy of sampling and testing data is guaranteed. The elbow is connected with a right angular pipeline, fluid resistance is small, and solution shear rate is low. A worm gear is used for driving a polymer injection high-pressure ball valve, opening and closing are fast, pressure relief combination design is adopted, high-pressure solution spraying is prevented, main components are welded, the device is prevented from being stolen effectively, the components are made of stainless steel, and chemical degradation is not generated. Safe and economic production of oil recovery is achieved.

Owner:陈大业

Polyester compositions, methods of manufacture, and uses thereof

A composition is disclosed, comprising, based on the total weight of the composition, a combination of from 44 to 80 weight percent of a thermoplastic poly(butylene terephthalate); from 20 to 50 weight percent of a thermoplastic poly(ethylene terephthalate) having an intrinsic viscosity of 0.5 to 0.8 deciliters per gram, measured in a 60:40 by weight phenol / 1,1,2,2-tetrachloroethane mixture at 23° C. using a relative viscometer operating with a closed loop system, which measures the solvent and sample viscosity simultaneously; from 5 to less than 20 weight percent of a talc filler having an average largest dimension of less than 0.9 micrometers, a median particle size of less than 0.9 micrometers, or both; and from 0.1 to 0.5 weight percent of a mold release agent. The compositions are useful in the manufacture of lighting articles, which can be directly metallized without the inclusion of a base coat.

Owner:SABIC GLOBAL TECH BV

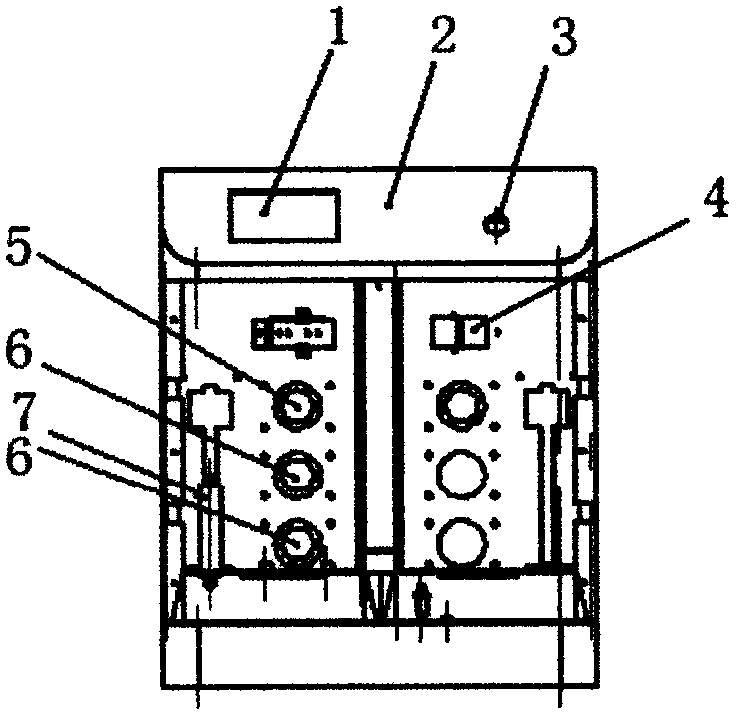

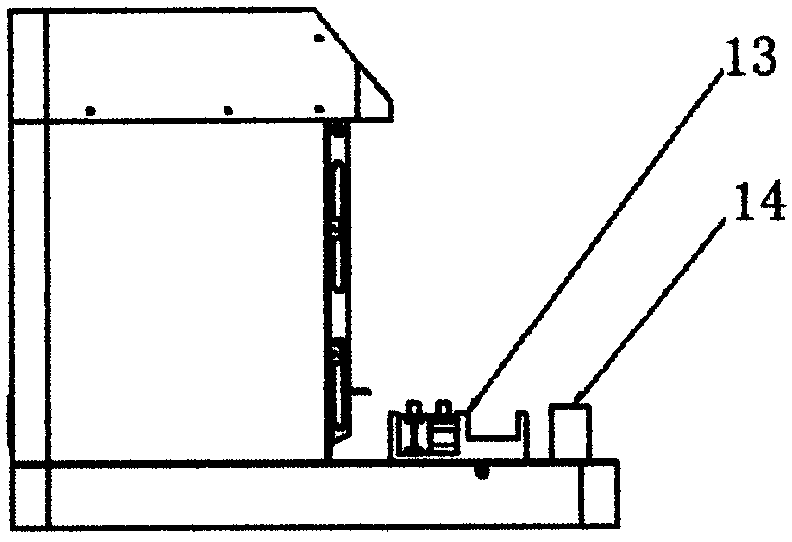

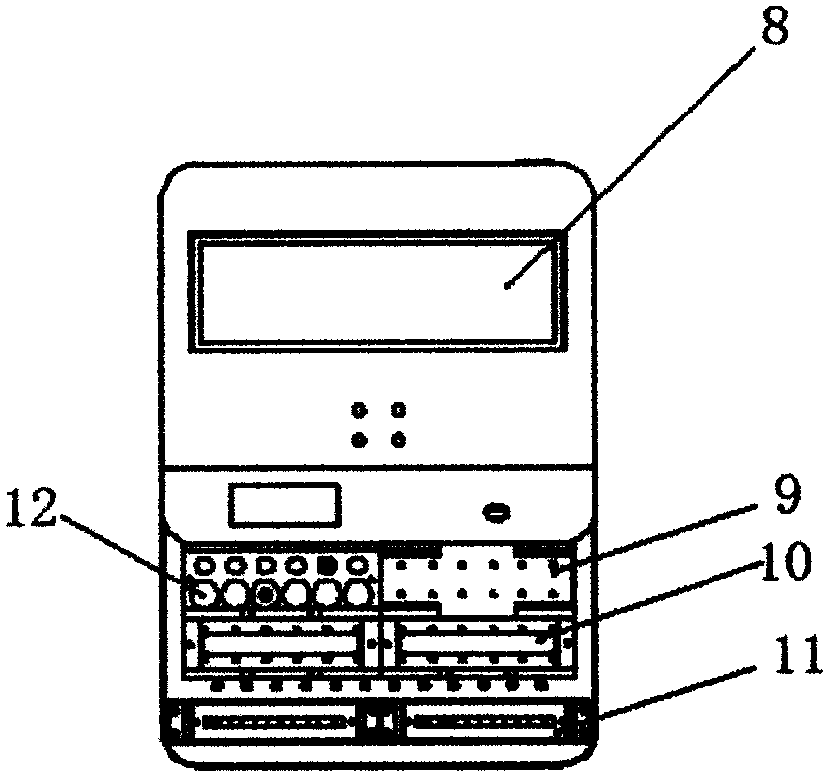

Immunoaffinity column operating device

PendingCN109669033AEasy to useControllable flow rateComponent separationBiological testingPositive pressureEngineering

The invention relates to improvement of a liquid chromatogram pretreatment instrument, in particular to an immunoaffinity column operating device. A solution tray is located on the rear part of the top end of a case, and thus the space for storing a solution bottle is omitted; and a cleaning pool is located at the front end of the case, a part of the cleaning pool is used for storing sample bottles and recovery bottles, and the other part of the cleaning pool serve as a cleaning part used for an injection needle. The cleaning part is provided with a corresponding cylindrical hole according tothe position of the injection needle, the injection needle is directly put into the hole when cleaned, and the inner wall and the outer wall of the needle are cleaned simultaneously. The problems thatas for an existing immunoaffinity column, the operation mode is long in time, the flow rate of liquid is uncontrollable, and the influence of sample viscosity and cleanliness is large are solved; andaccording to the immunoaffinity column operating device, multiple channels are formed, the flow rate of the liquid can be controlled, positive-pressure sample feeding is achieved, the sample recoveryrate is high, stable and consistent, a pipeline can be cleaned, and the low-residual effect is achieved.

Owner:无锡冠一生物科技有限公司

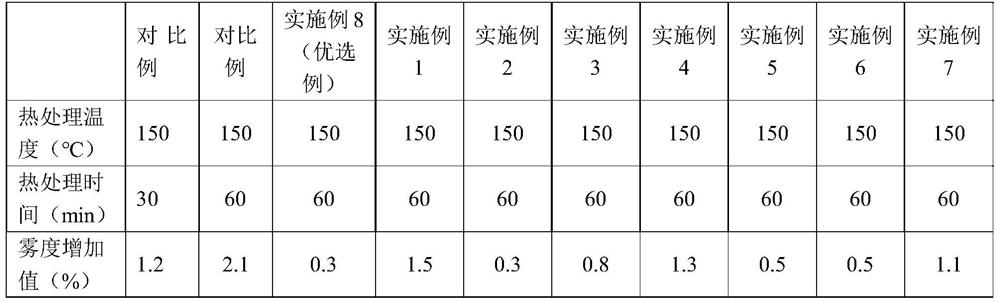

Low-precipitation polyester film and preparation method thereof

The invention discloses a low-precipitation polyester film which is prepared from the following raw materials in parts by mass: 95-100 parts of low-precipitation polyester chips and 0-5 parts of an anti-blocking agent, wherein the two surfaces of the low-precipitation polyester film are coated with the same or different coating liquids. The preparation method of the low-precipitation polyester chips comprises the following steps: mixing terephthalic acid and ethylene glycol according to a molar ratio of 1:(1.1-2.0), and adding an auxiliary agent for polymerization, wherein the esterification temperature is 220-260 DEG C and the polycondensation temperature is 260-290 DEG C; when the viscosity of the sample is between 0.40 dL / g and 0.55 dL / g, ending the reaction to obtain a copolyester melt; and conducting extruding to form strips by using nitrogen, condcuting granulating to obtain slices, carrying out solid-phase polycondensation on the slices, and ending the reaction when the viscosity of a sample is 0.60-0.80 dL / g to obtain the low-precipitation polyester chips. The invention also discloses a preparation method of the low-precipitation polyester film. The low-precipitation polyester film prepared by the invention has better thermal stability and low precipitation property, the haze is lower than 1%, and meanwhile, the haze rising value is less than 0.5% after the film is heated for 2 hours at 150 DEG C, so that the phenomenon of atomization is avoided when the film is heated.

Owner:YIHUA TORAY POLYESTER FILM CO LTD

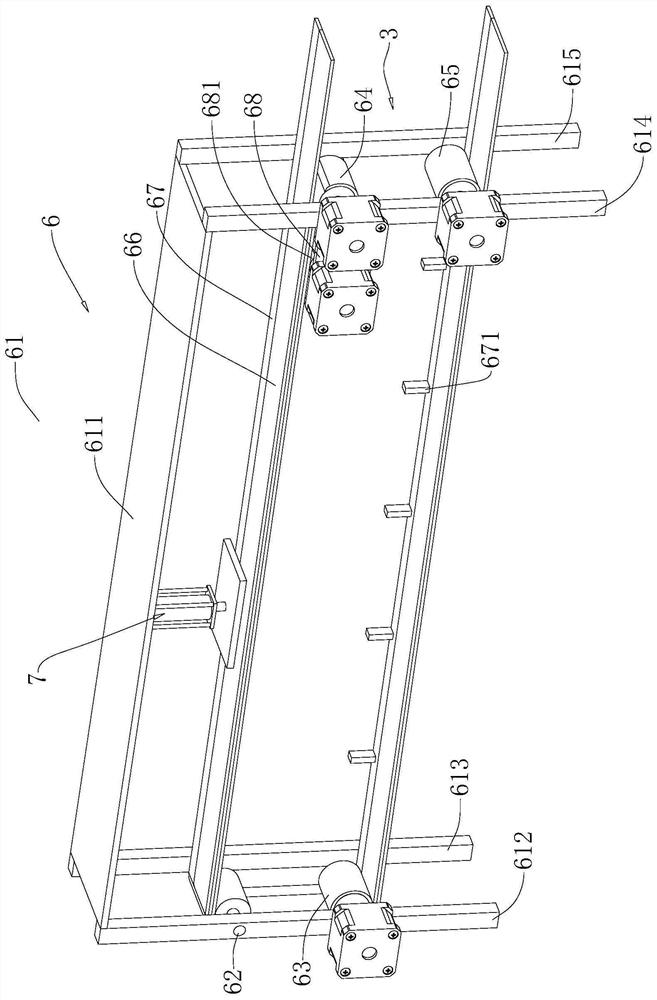

Stepping scanning torque measuring device in magnetic-levitation bearing support structure

InactiveCN102830041BPrevent twistingOvercome the shaking phenomenonFlow propertiesMeasurement deviceElectric machine

The invention discloses a use method of a stepping scanning torque measuring device in a magnetic-levitation bearing support structure, particularly the use method of equipment for detecting the change of blood flow. The use method comprises the steps that: samples are filled in gaps between a measuring outer cylinder and a measuring inner cylinder, a big wheel is driven to rotate by rotation of a stepping motor, a stop position of an oscillating bar is detected by a displacement detection device, the measuring outer cylinder rotates clockwise in a certain speed and drives the samples to rotate, the measuring inner cylinder is driven by a friction force generated by sample viscosity to rotate, a center shaft and the horizontal oscillating bar is driven to rotate by the measuring inner cylinder, meanwhile a balance spring is tightened under the drive of the center shaft, when an elastic counter-acting force generated by the balance spring is equal to the friction force generated by the sample viscosity, the measuring inner cylinder reaches a balance state, at this time the oscillating bar stops at a certain position, the stepping motor rotates clockwise and drives the displacement detection device to rotate clockwise, thus the sample viscosity can be calculated according to a direct ratio relation between the displacement of the horizontal oscilating bar and the step number of the stepping motor.

Owner:山东美医林电子仪器有限公司

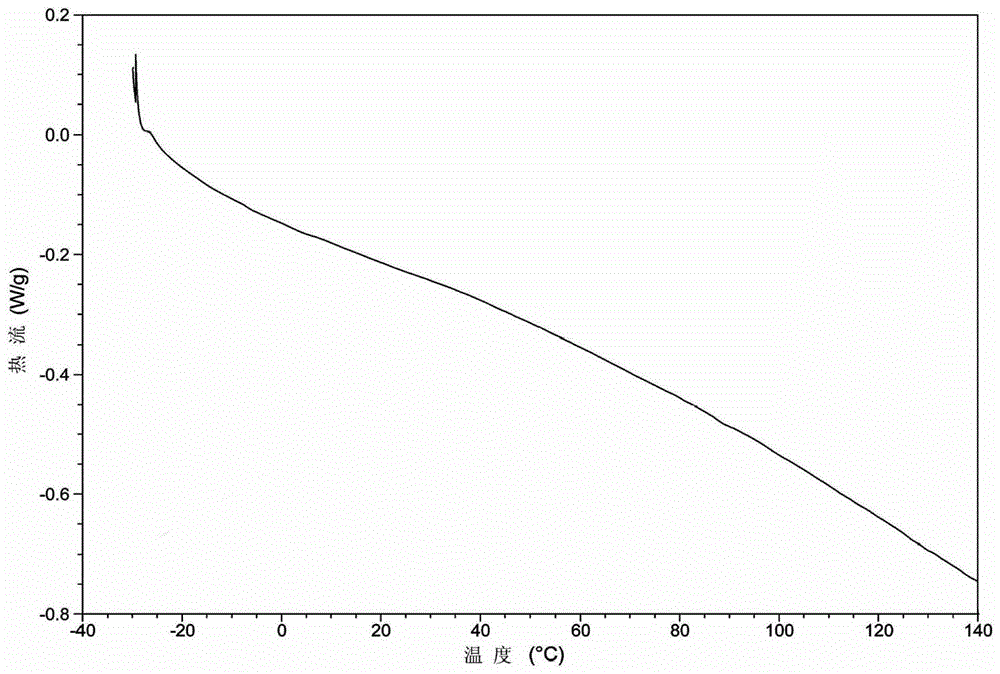

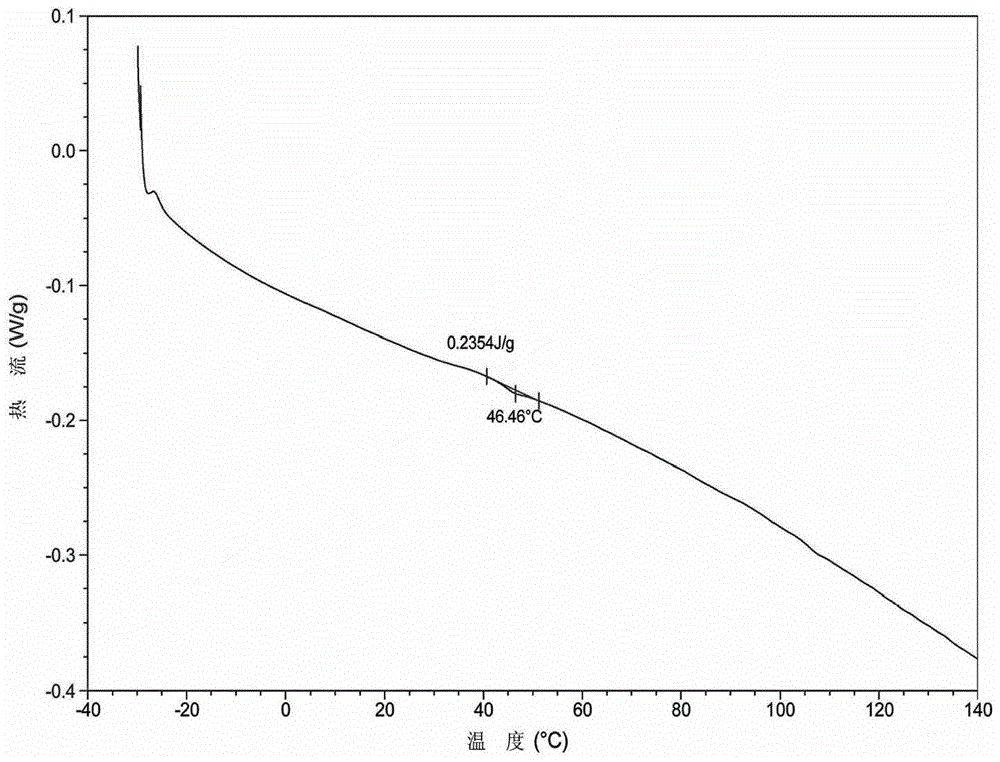

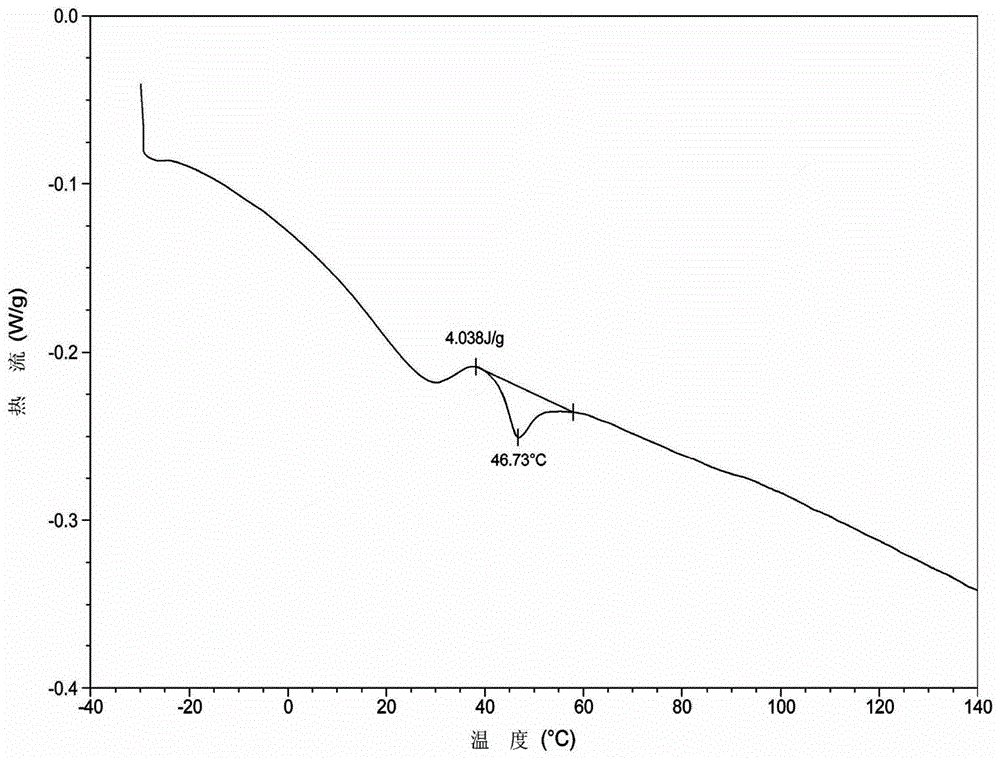

A method for detecting viscosity index improvers containing semi-crystalline gums

ActiveCN103837566BHigh detection sensitivityThe test result is accurateMaterial heat developmentViscosity indexBase oil

The invention relates to a method for detecting a viscosity index improving agent containing hypocrystalline glue. The method comprises the following steps: separating dry glue from a viscosity index agent; placing a dry glue sample in a crucible, removing heat history under a DSC (Differential Scanning Calorimetry) mode; performing temperature rise scanning under an MDSC (Modulated Differential Scanning Calorimetry) mode and recording a curve; integrating a fusion endothermic peak in an interval of 40-60 DEG C on the curve and calculating a heat enthalpy value; judging whether the viscosity index contains the hypocrystalline glue according to the heat enthalpy value. The method has the characteristics of eliminating interference of factors such as sample viscosity, base oil variety and ethylene-propylene rubber batch, being capable of detecting a glue solution with a ratio of the hypocrystalline glue to an amorphous glue of 1:9 or even lower, and being high in sensitivity and reliability.

Owner:PETROCHINA CO LTD

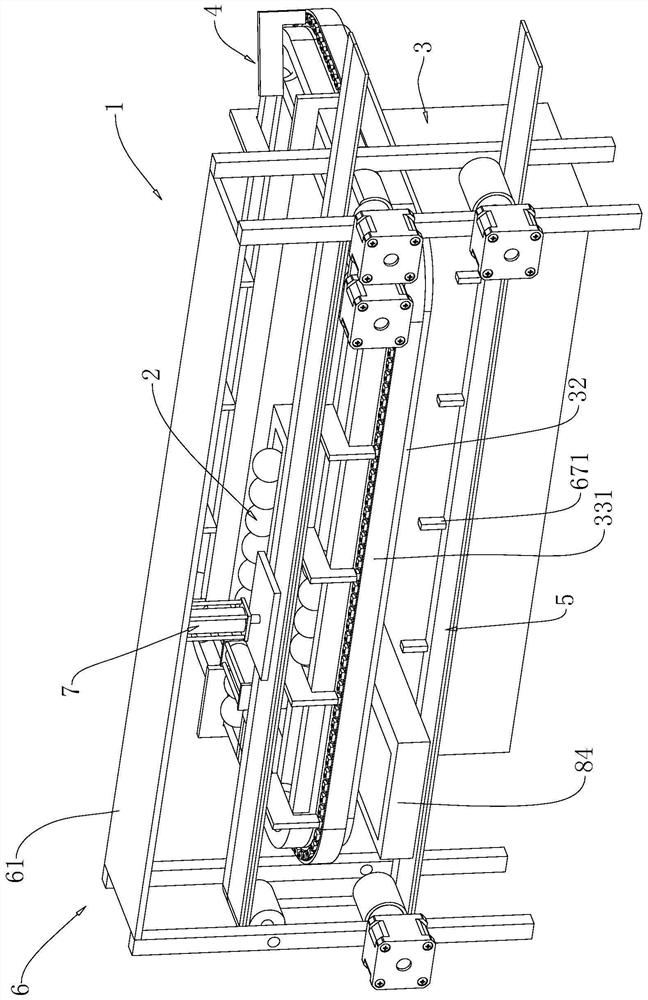

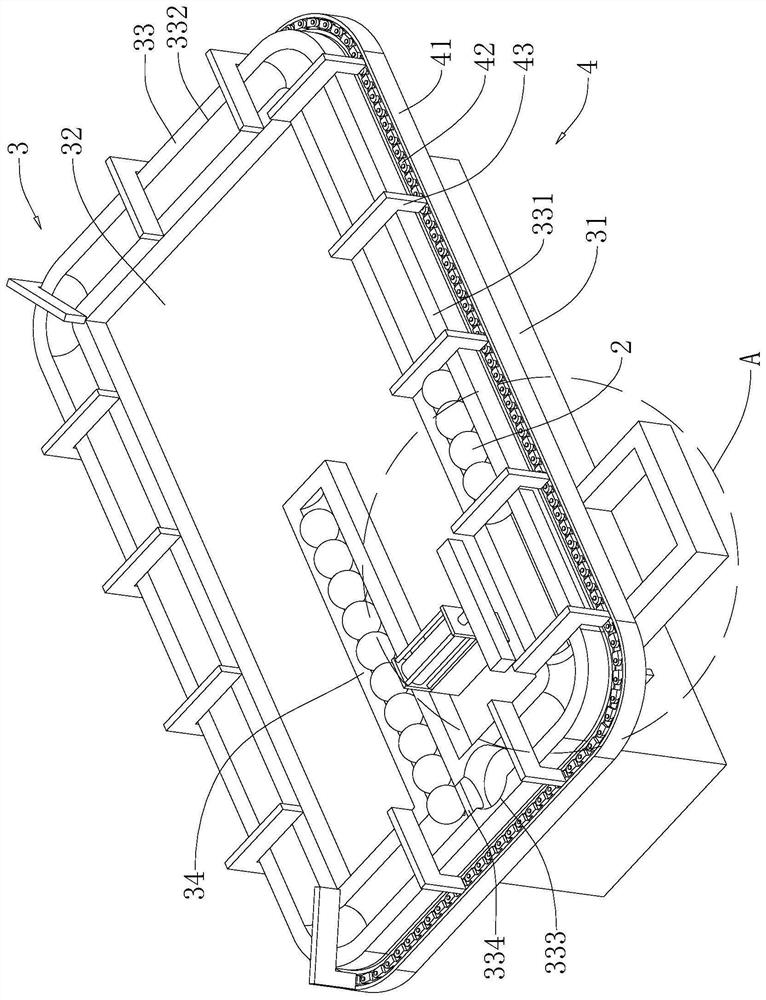

A hot melt adhesive sample viscosity measuring device

The present application relates to a hot-melt adhesive sample viscosity measuring device, which includes a first frame, on which a horizontally placed placing plate is installed, and a material conveying frame is installed on the upper end of the placing plate. A plurality of test balls are placed in the material conveying frame, and the diameters of the plurality of test balls are the same, and the quality is different; one side of the first frame is provided with a sample conveying mechanism for conveying the sample body to the test ball. device, the first rack is equipped with a pressing component that presses the sample body toward the test ball side so that the sample body contacts the test ball, and the material delivery frame is formed with a discharge that runs through the placement plate. The discharge groove is located on the side of the pressing assembly away from the input direction of the test ball. The application has the effects of shorter hot melt adhesive detection time and higher hot melt adhesive detection efficiency.

Owner:靖江市金马胶粘制品制造有限公司

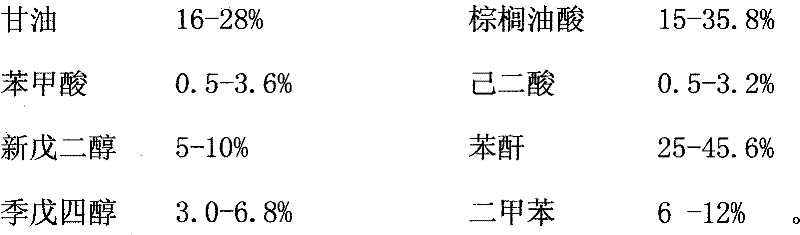

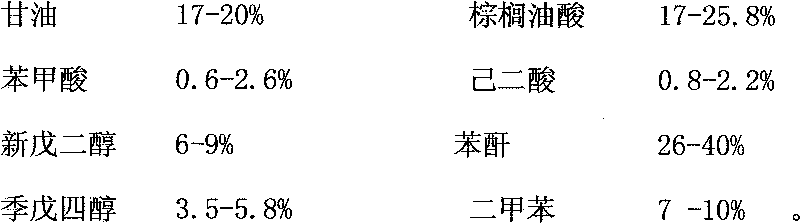

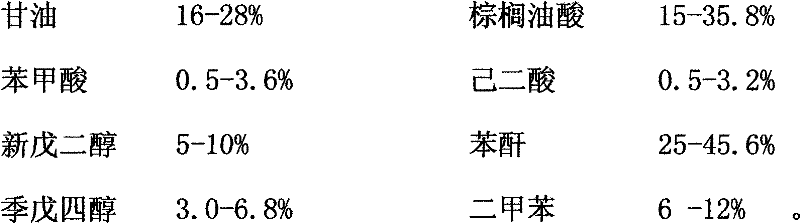

Bright alkyd resin for interior decoration and furniture coating and preparation method thereof

The invention discloses a bright alkyd resin for interior decoration and furniture coating, which is composed of the following raw materials: glycerin, palmitoleic acid, benzoic acid, adipic acid, neopentyl glycol, phthalic anhydride, pentaerythritol and xylene . Its preparation method comprises the steps of: a. putting palmitoleic acid, benzoic acid, adipic acid, glycerin, neopentyl glycol, phthalic anhydride, pentaerythritol and xylene into a reactor at one time, heating and starting stirring; b. Zhongtong carbon dioxide gas protects the temperature, raises the temperature to 130°C-180°C, and keeps it warm for 1-3 hours. ; c, take a sample to measure the viscosity in step b, when the viscosity reaches a predetermined value, rapidly cool to 130°C-180°C to obtain a modified alkyd resin; d, transfer the modified alkyd resin in step c to another Add 2.5-8.5% xylene into the kettle, and mix evenly to obtain the product water-white alkyd resin liquid of the present invention.

Owner:四川巴德士新材料有限公司

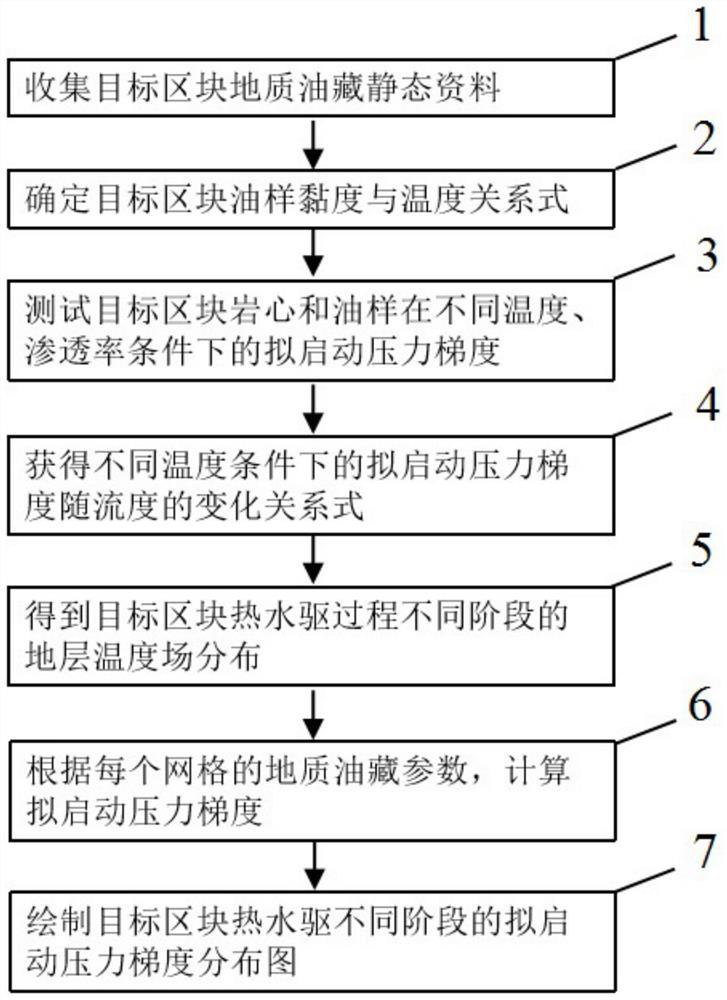

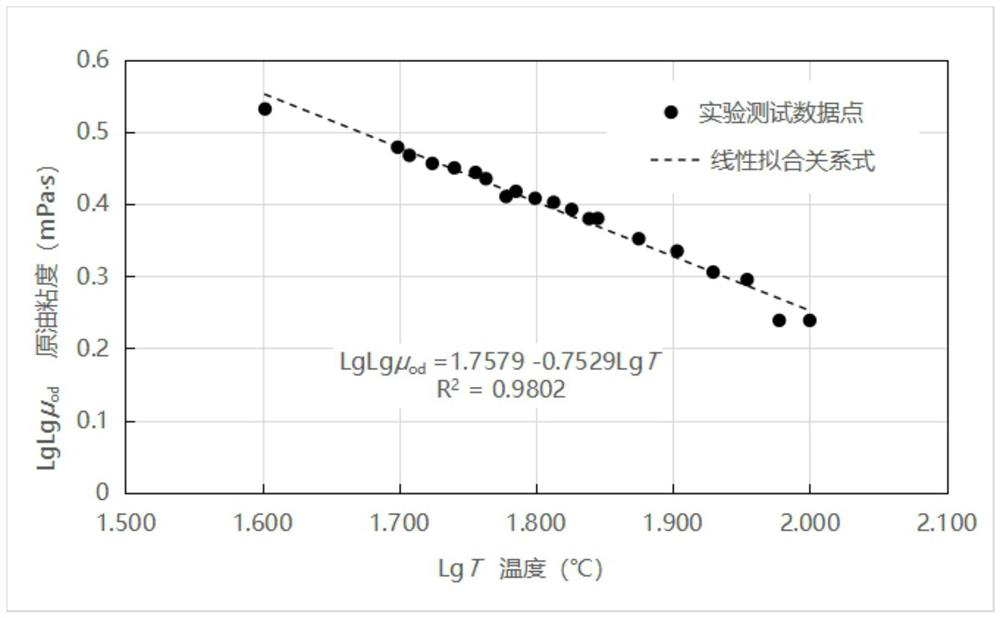

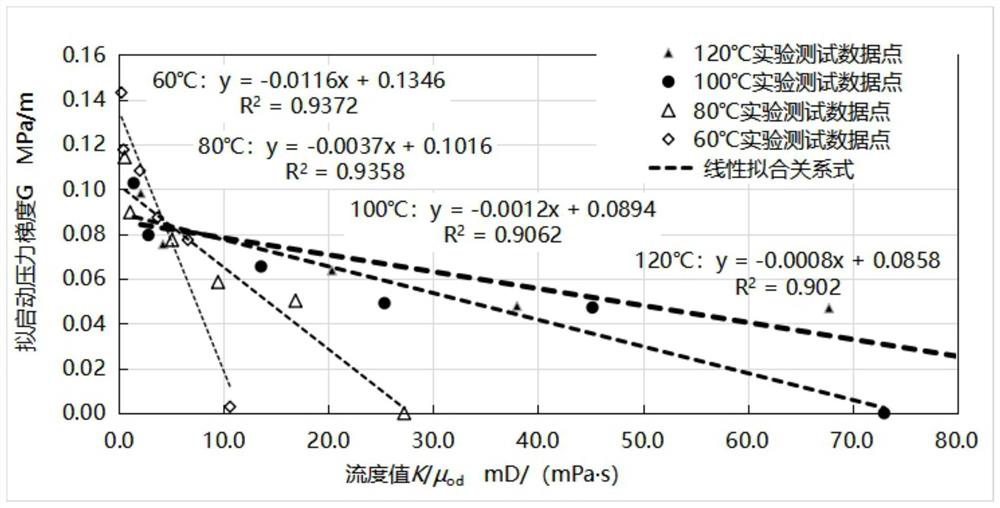

Method for determining dynamic change of pressure gradient to be started after heavy oil water drive is converted into hot water drive

PendingCN114018782ADetermine productivityDetermining the limit well spacingFluid removalPermeability/surface area analysisReservoir typeRock core

The invention discloses a method for determining dynamic change of a pressure gradient to be started after heavy oil water drive is converted into hot water drive. The method comprises the following steps: 1, collecting geological reservoir static data of a target block; 2, determining a relational expression of oil sample viscosity and temperature of a target block; 3, testing the quasi-starting pressure gradients of the core and the oil sample of the target block under different temperature and permeability conditions; 4, obtaining a change relational expression of the starting pressure gradients at different temperatures along with the fluidity; 5, obtaining formation temperature field distribution of different stages of the hot water flooding process of the target block; 6, calculating a starting pressure gradient according to the geological reservoir parameters of each grid; and 7, drawing starting pressure gradient distribution diagrams of different stages of hot water drive of the target block. According to the method, the relational expressions of the quasi-starting pressure gradients, the permeability, the viscosity, the temperature and the like of the heavy oil reservoirs of different geological reservoir types are quantitatively represented; in addition, formation temperature field distribution of different stages of hot water injection flooding of the target block is obtained; and the production pressure difference and the limit well spacing of the target block are determined.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Polyacrylamide aqueous solution mine-field sampling viscosity stabilizing agent, and using method

InactiveCN104764634AAvoid degradationGood application effectWithdrawing sample devicesPreparing sample for investigationScavengerThiourea

The invention provides a polyacrylamide aqueous solution mine-field sampling viscosity stabilizing agent. The polyacrylamide aqueous solution mine-field sampling viscosity stabilizing agent is prepared from a Fe2+ ion complexing agent, a radical scavenger, and a deoxidant at a molar ratio of 2:0.5-1.5:0.5-1.5. The Fe2+ ion complexing agent is dipyridyl; the radical scavenger is a phenol mixture, and the phenol mixture is composed of phenol and resorcinol at a molar ratio of 3:0.5-1.5; and the deoxidant is thiourea. The polyacrylamide aqueous solution mine-field sampling viscosity stabilizing agent is capable of avoiding viscosity reduction of polyacrylamide aqueous solution in sampling processes caused by degradation; it is shown by comparing mine-field sampled polyacrylamide aqueous solution with in-door simulated polyacrylamide aqueous solution that mine-field sampling is capable of ensuring authenticity of sampling viscosity, and excellent application effect of mine-field sampling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Colloidal gold immunofiltration quantitive detection method and reagent kit

The invention relates to clinical immunodiagnosis reagents and preparation methods thereof, and discloses a colloidal gold immunofiltration quantitive detection reagent kit and a method for detecting antigens and antibodies by colloidal gold immunofiltration quantitive detection. One or two quality control lines or points which contain known to-be-detected substances are added on the colloidal gold immunofiltration quantitive detection reagent kit. In one reaction, change of color developing degree of detection lines (points) is relevant with change of color developing degree of the quality control lines (points) significantly, deviation of the detection lines (points) can be corrected by the quality control lines (points), and thus, variation caused by deviation of raw materials (nitrocellulose membranes, water absorbent pads), sample viscosity, temperature and sample adding quantity and the like can be overcome effectively.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Coal sample viscosity judgment method used for coal sample collection and preparation integration

ActiveCN104914010AGuaranteed sample representativenessMeet the precision requirementsFlow propertiesPreparing sample for investigationEngineeringDrive motor

The invention discloses a coal sample viscosity judgment method used for coal sample collection and preparation integration. The method comprises the following steps: S1: setting a distinguishing threshold value; putting coal samples with standard viscosity in collection and preparation integrated coal sample detection equipment, and detecting the real-time current value of a driving motor in a rotary wiping device as the distinguishing threshold value when wiping operation is carried out on the coal samples with standard viscosity in a rotary wiping position; S2: monitoring the coal sample viscosity in real time; during normal operation of the collection and preparation integrated coal sample detection equipment, monitoring the current value of the driving motor in the rotary wiping device in the integrated coal sample detection equipment in real time when the coal samples pass through the rotary wiping position; sending the coal samples to drying equipment to be processed when the current value is more than the distinguishing threshold value; sending the coal samples to a next position behind the rotary wiping device in the collection and preparation integrated coal sample detection equipment to be processed when the current value is less than or equal to the distinguishing threshold value. The method has the advantages of simple principle, extreme simplicity and convenience in operation, high precision, and the like.

Owner:HUNAN SUNDY SCI & TECH DEV

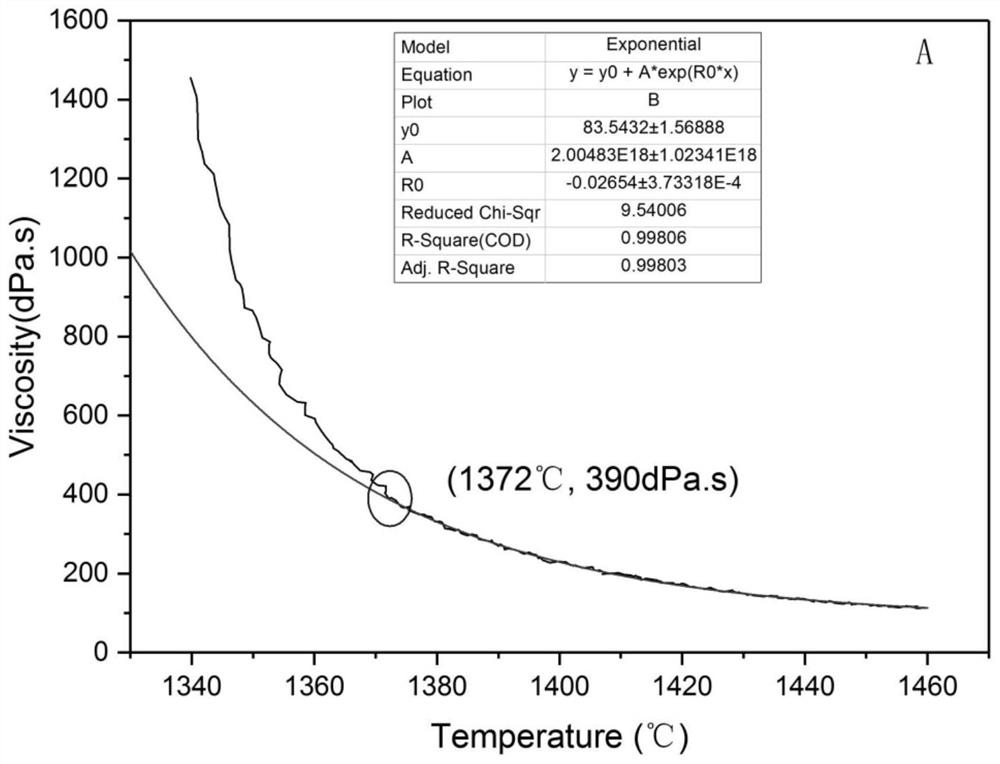

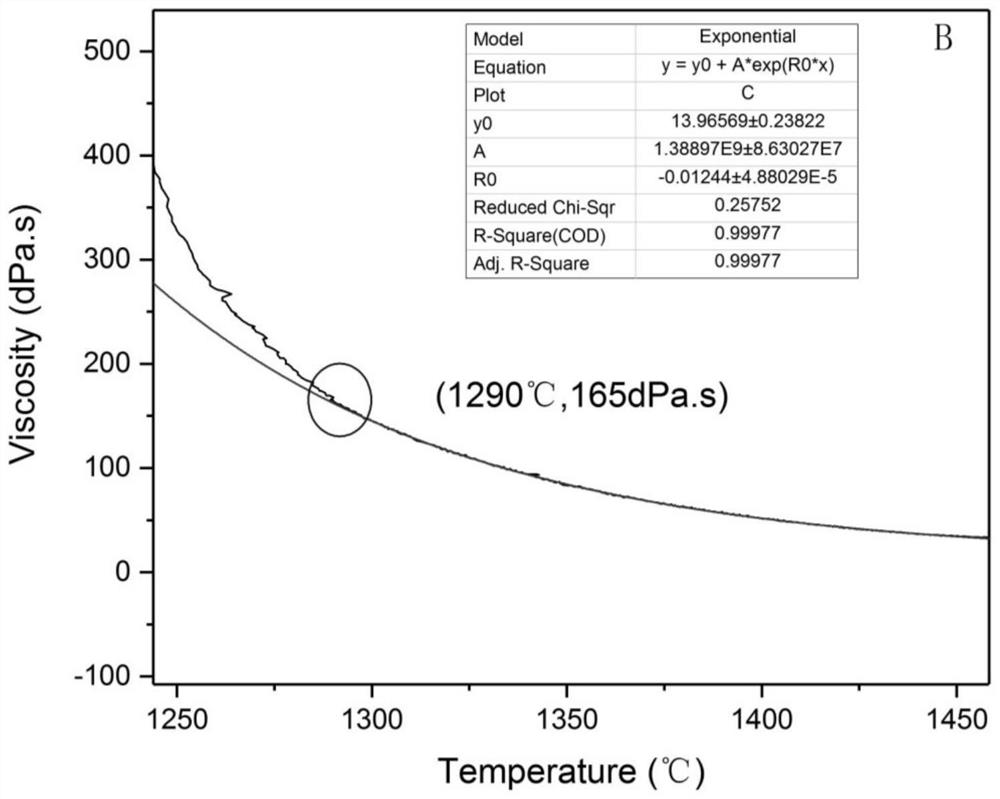

Method for quantifying crystallization temperature upper limit through basalt melt viscosity mutation

PendingCN114371104AThe upper limit of the crystallization temperature is accurately determinedProven reliabilityFlow propertiesPreparing sample for investigationTemperature curveEngineering

The invention relates to a method for accurately quantifying a crystallization temperature upper limit through basalt melt viscosity mutation, which comprises the following steps of: preparing a sample, melting and homogenizing, testing the viscosity of the sample to obtain a viscosity-temperature curve, and fitting the viscosity and the temperature: selecting a high-temperature section with a certain length on the viscosity-temperature curve by taking the highest temperature as a starting point, an exponential function model: eta (T) = eta 0 + A * exp (R0 * T) is adopted for fitting the viscosity-temperature correlation, a viscosity-temperature fitting curve is prolonged, and the abscissa of an inflection point C where the viscosity-temperature curve and the fitting curve are separated is the crystallization temperature upper limit TC. According to the method, accurate determination of the upper limit of the crystallization temperature of the basalt melt through sudden change of the high-temperature viscosity of the basalt melt is proposed for the first time, the technical problem that accurate determination of the upper limit of the crystallization temperature of the melt is lacked in the field of continuous basalt fiber preparation is solved, and an important reference is provided for reasonable setting of the wire drawing temperature.

Owner:GUIZHOU MINZU UNIV

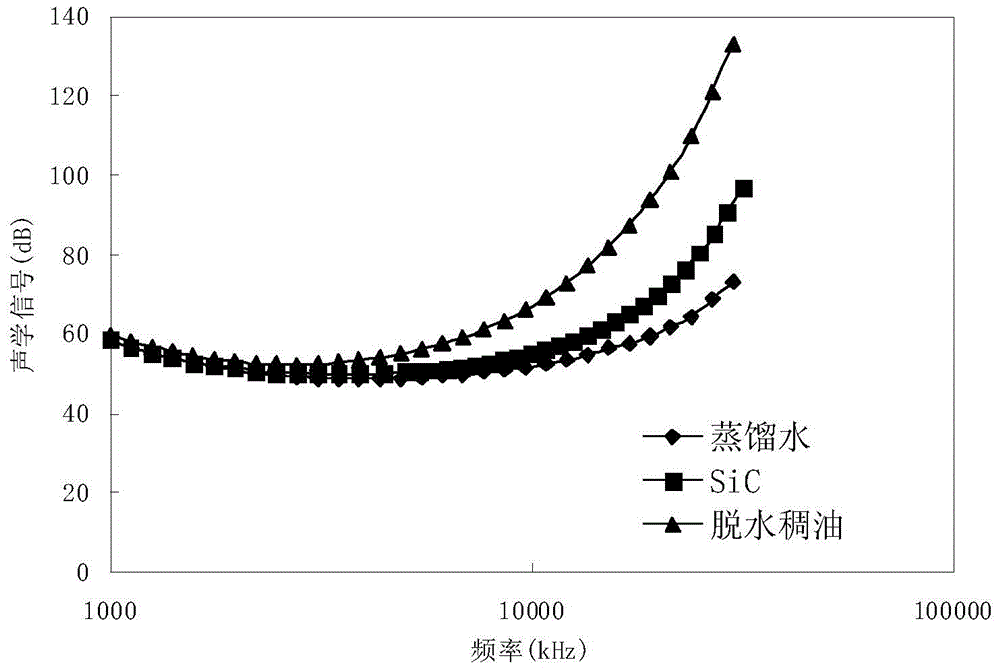

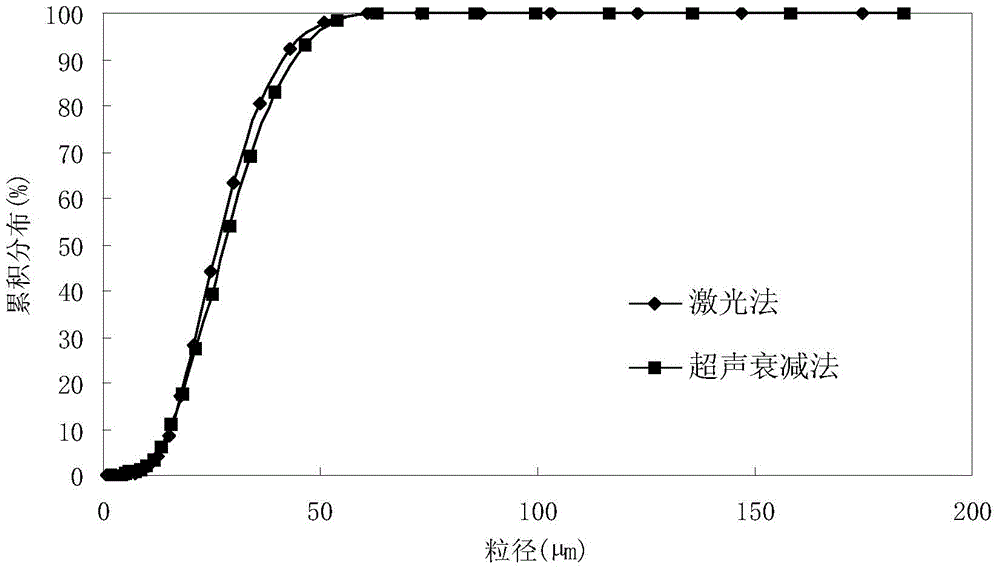

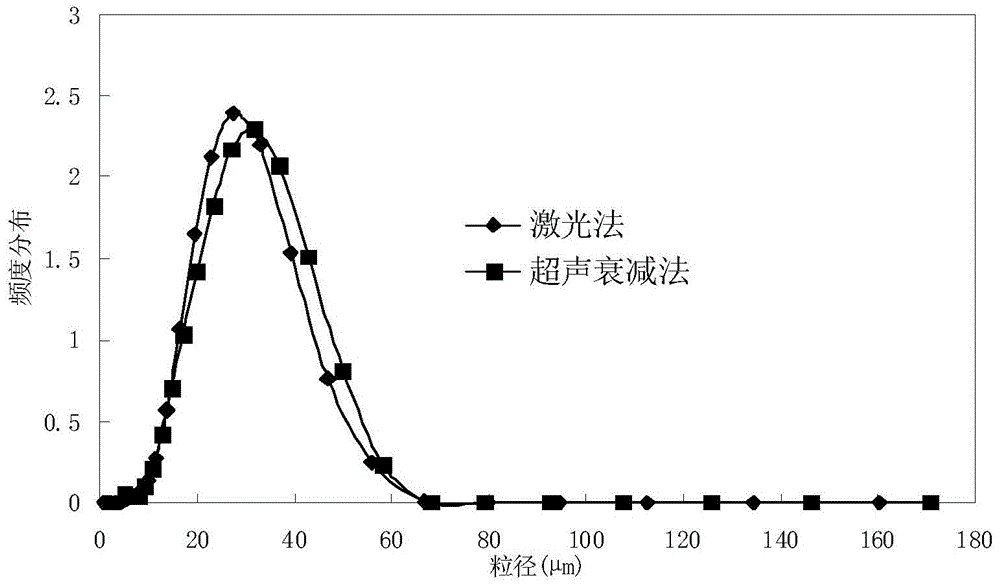

A method for detecting particle size of heavy oil/water particles

The invention provides a particle size detection method of opaque heavy oil in water, which specifically includes: adding a separate continuous phase sample water into the sample tank of the ultrasonic attenuation particle size meter, inputting the density of the sample to be tested, and The ultrasonic attenuation spectrum test is carried out under the frequency conditions, and the test results of the acoustic characteristic parameters of the continuous phase are saved; the separate dispersed phase sample heavy oil is added to the sample tank of the ultrasonic attenuation particle size analyzer, and the density of the sample to be tested is input. The ultrasonic attenuation spectrum test is carried out separately, and the test results of the acoustic characteristic parameters of the dispersed phase sample are saved; The measured acoustic information of the continuous phase and dispersed phase samples, select the test frequency conditions of the continuous phase and dispersed phase to test the ultrasonic attenuation spectrum of the sample to be tested, and obtain the opaque water of the opaque O / W viscous oil system based on the test results Including particle size and distribution of heavy oil particles.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com