Immunoaffinity column operating device

A column operation and immunoaffinity technology, which is applied in the field of immunoaffinity column operation devices, can solve the problems of great influence of sample viscosity and cleanliness, large interference difference of sample recovery rate, uncontrollable liquid flow rate, etc., and achieve sample recovery rate Stable and consistent, controllable liquid flow rate, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

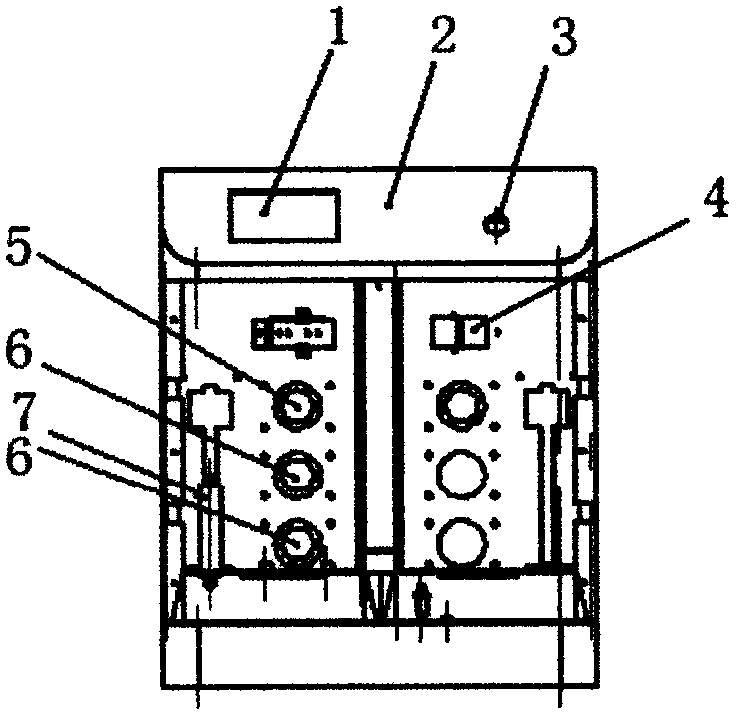

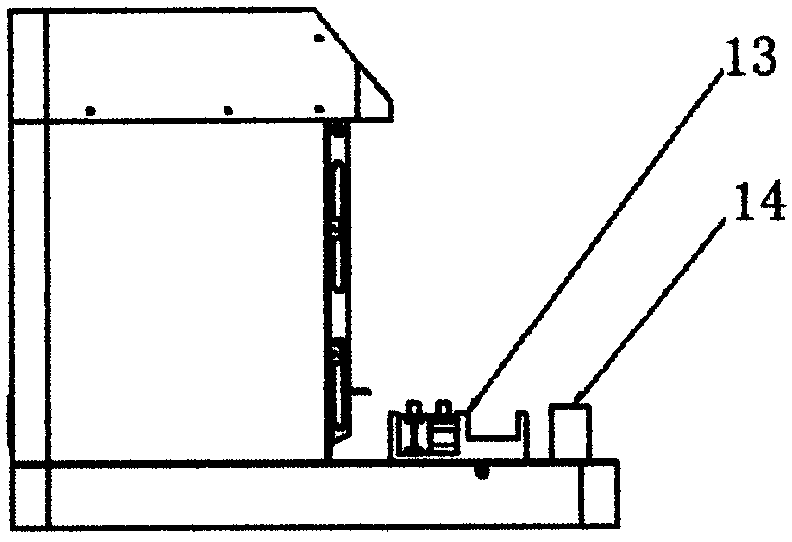

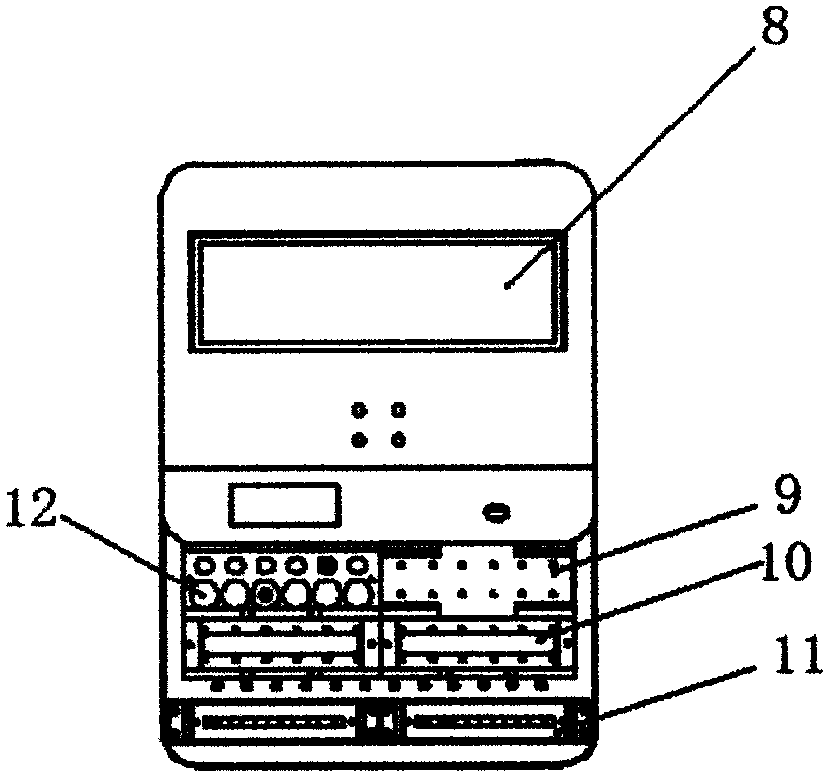

[0022] see Figure 1-Figure 6 As shown, the technical solution adopted in this specific embodiment is: it consists of a liquid crystal touch control panel 1, a chassis 2, a power control button 3, a three-way solenoid valve 4, a sixteen-channel switching valve 5, a six-channel switching valve 6, and a syringe pump. 7. The solution tray 8, the injection needle holder 9, the cleaning pool 13, and the column connection device 14 are composed. The solution tray 8 is located at the rear of the top of the cabinet 2, which saves the space for placing the solution bottle; the cleaning pool 13 is located at the front end of the cabinet 1. One part of the pool 13 is a part 12 for placing sample vials and recovery bottles, and another is a washing part 10 for injection needles.

[0023] The cleaning part 10 is provided with a corresponding cylindrical hole according to the position of the injection needle, and the injection needle is directly placed in the hole during cleaning, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com