Method for quantifying crystallization temperature upper limit through basalt melt viscosity mutation

A technology of crystallization temperature and melt viscosity, which is applied in the field of continuous basalt fiber production and preparation, can solve problems such as lowering of mechanical properties, mismatching of drawing temperature and upper limit of crystallization temperature, broken wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0024] Sample preparation: Take 500g each of the basalt A and B ore samples to be tested, remove impurities such as soil, and crush the samples with a jaw crusher.

[0025] Melting homogenization: put the crushed sample into a platinum crucible, and melt and homogenize it at a high temperature of 1500°C for 10 hours.

[0026]Viscosity test: Use a high-temperature rotational viscometer to test the viscosity of the basalt melt after melting and homogenization. The data collection temperature range is 1500°C-1200°C, and the data collection speed is kept at about 1 point / °C.

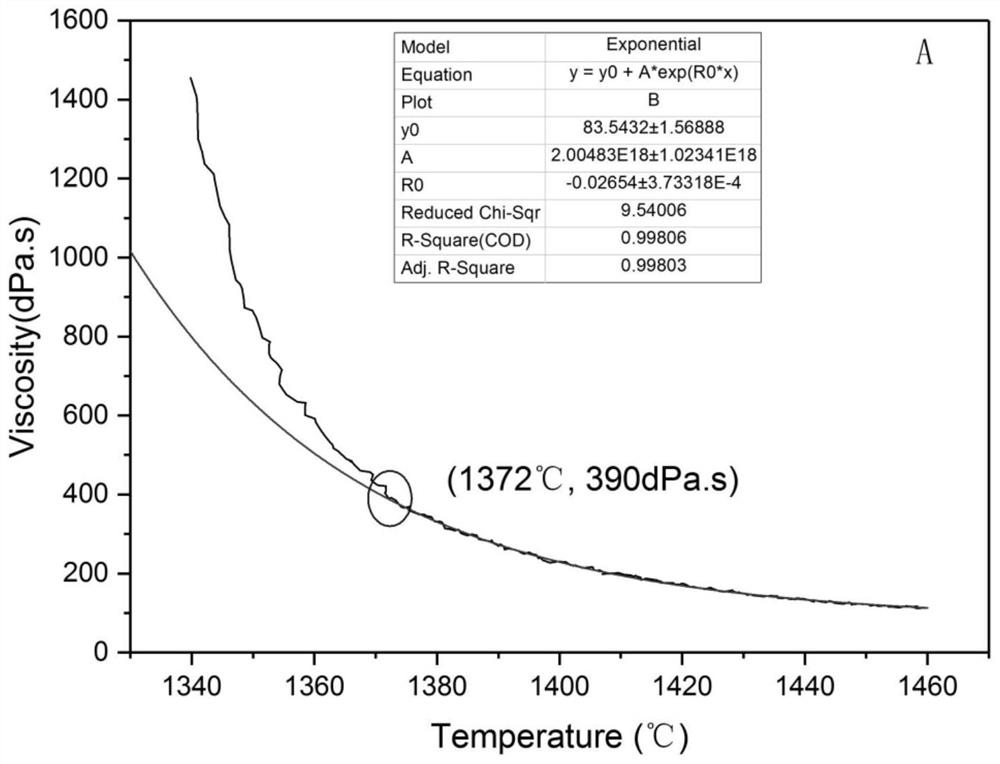

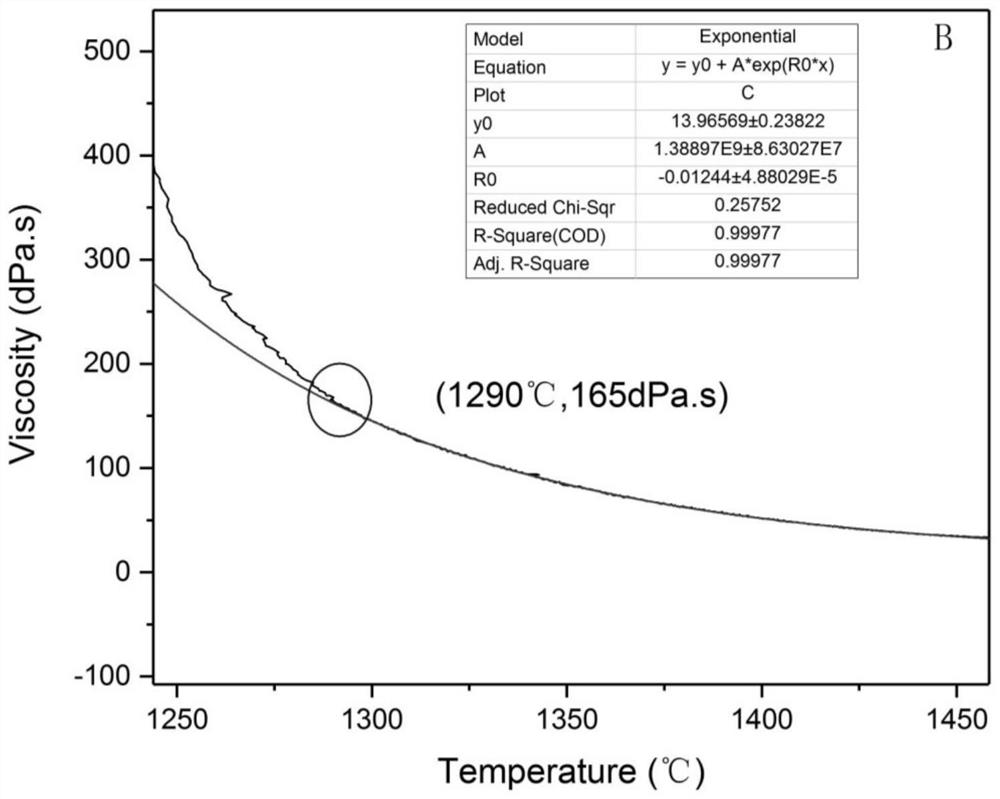

[0027] Viscosity temperature fitting: on the viscosity temperature curve, starting from the highest temperature, select a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com