Method for measuring liquid viscosity in capillary tube based on micro volume sample measurement

A test method and capillary technology, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of blank, slow heating and cooling, large sample volume, etc., and achieve good practicability, reduce consumption, and small sample consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A capillary viscosity testing method based on micro sample measurement, the flow path is filled with a flow medium, and then the sample fluid is introduced, and the flow medium pushes the sample to flow through the capillary 5; when the viscosity of the sample fluid is small or the sample fluid is compressed under high pressure When the small volume is negligible, set the volume V of the sample liquid to be greater than the capillary 5 volume V c ; When the viscosity of the sample fluid is very high and the volume of the sample fluid compressed under high pressure cannot be ignored, then multiple injections are performed and the volume V of each injection liquid is less than the capillary 5 volume V c .

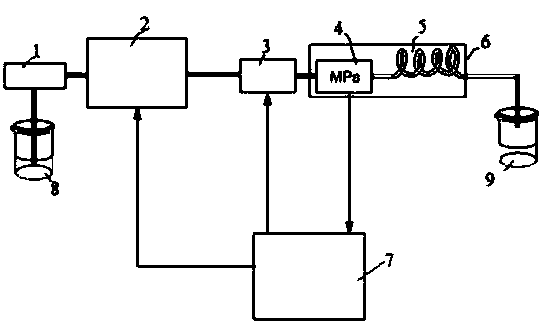

[0065] as attached figure 1 As shown, the flow medium is placed in the liquid storage bottle 8. After the flow medium passes through the degasser 1, it enters the constant flow high-pressure pump 2. The constant flow high-pressure pump 2 is regulated by the controlle...

Embodiment 2

[0074] This embodiment is optimized on the basis of embodiment 1, such as Figure 5 As shown, when the volume V of the sample liquid is greater than the volume V of the capillary c When the sample is completely filled with the capillary 5, the pressure difference between the two ends of the capillary 5 is ΔP, and the radius r, inner diameter d, length L, and flow rate Q of the capillary 5 can be calculated according to Poiseuille's law. shear rate shear stress

[0075] Such as Image 6 As shown, when the viscosity of the sample fluid is very high and the volume of the sample fluid compressed under high pressure is not negligible, two injections of different volumes are carried out, and the injection volumes are V 1 , V 2 , the pressure drop change of the sample from entering the capillary 5 to the process of completely excluding the capillary 5 is ΔP, and the time for the sample to pass through the capillary 5 is ΔT; the volume difference of the sample under high press...

Embodiment 3

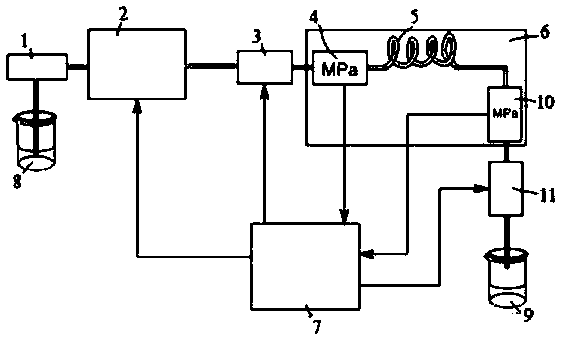

[0084] This embodiment is optimized on the basis of embodiment 1, such as figure 2 As shown, in order to expand the pressure range of the test system, a second pressure sensor 10 and a back pressure regulating device 11 can be added and connected to the outlet side of the capillary 5 . The back pressure regulating device 11 is controlled by the controller 7 and can generate a specified flow resistance. The second pressure sensor 10 returns the pressure value to the controller 7 in real time at a certain sampling rate.

[0085] The sampling system is responsible for introducing a specified volume of sample into the high-pressure fluid pipeline, which can be realized by using a flow-through sampling valve widely used in liquid chromatography or other structures with similar functions. The temperature control system is used to ensure that the temperature of the sample is constant when passing through the capillary 5, which can be realized by using a thermostat 6 or a water bath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com