A method for detecting viscosity index improvers containing semi-crystalline gums

A technology of viscosity index and improver, which is applied in the detection field of lubricating oil additives, and can solve the problems such as the reduction of yield stress value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

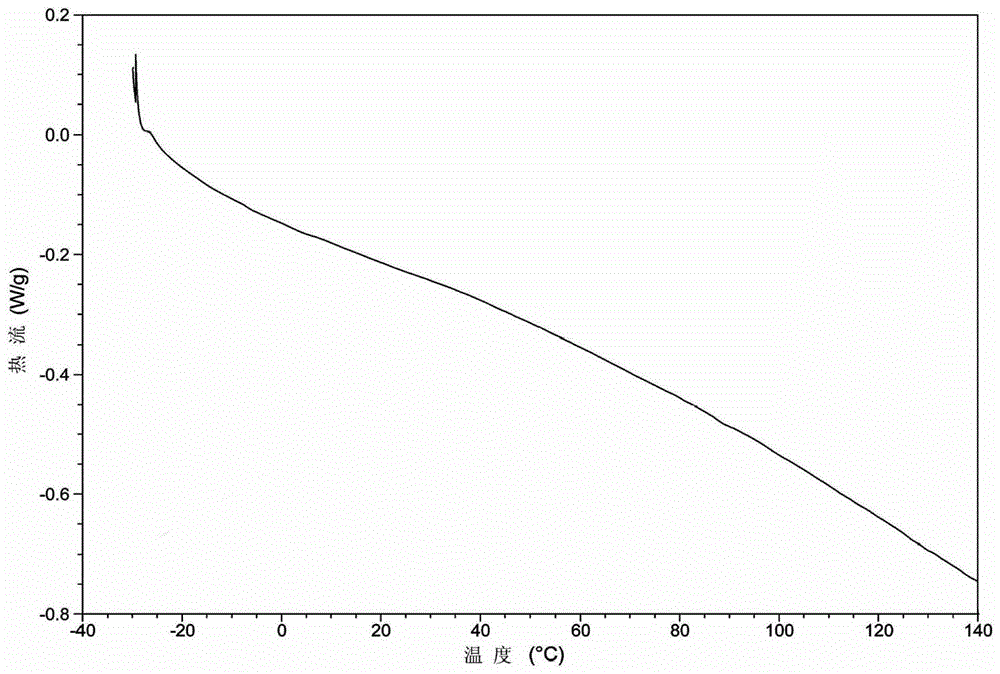

[0023] The present embodiment carries out detection operation according to the following steps:

[0024] 1. Take 10% amorphous rubber and 90% base oil, add them into a beaker and mix, heat to 80°C, stir until the amorphous rubber is completely dissolved in the base oil, and improve the viscosity index of the prepared ethylene-propylene copolymer The reagent samples were cooled in a dry environment.

[0025] 2. According to the petrochemical and petroleum product industry standard SH / T0034, separate the ethylene propylene rubber from the ethylene propylene copolymer viscosity index improver sample and store it in a dry environment.

[0026] 3. Turn on the differential calorimetry scanner (DSC) under nitrogen protection conditions, and purge the DSC instrument with dry nitrogen at a stable airflow rate during the entire detection process.

[0027] 4. Take about 3.0mg~4.0mg of ethylene-propylene glue and dry glue, put it into a differential calorimetry scanner to seal the alumin...

Embodiment 2

[0031] Test sample preparation, add amorphous glue and semi-crystalline glue to the base oil at a ratio of 9:1, the two dry glues account for 10% of the total, heat to 100°C, and stir until the dry glue is completely dissolved in the base oil , Place the prepared ethylene-propylene copolymer viscosity index improver sample in a dry environment to cool.

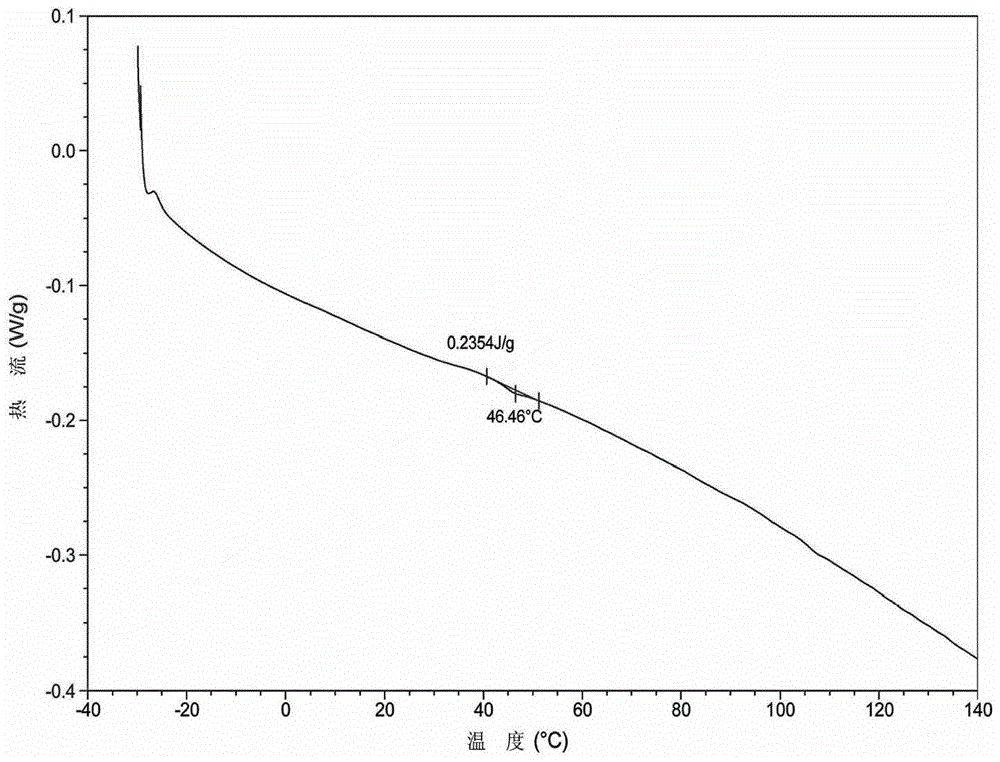

[0032] Detect according to the step and condition in embodiment 1, the temperature rising curve that draws is shown in figure 2 , it can be seen from the figure that a melting endothermic peak appeared at 46.46°C. After integrating the peak, the enthalpy value was 0.2354J / g, which was greater than the criterion of 0.1J / g. The test result was that the sample Contains semi-crystalline gum, which is consistent with the addition of semi-crystalline gum in the prepared sample.

Embodiment 3

[0034] Test sample preparation, add 10% semi-crystalline rubber to 90% base oil, heat to 100°C, stir until the dry rubber is completely dissolved in the base oil, and place the prepared ethylene-propylene copolymer viscosity index improver sample Cool in a dry environment.

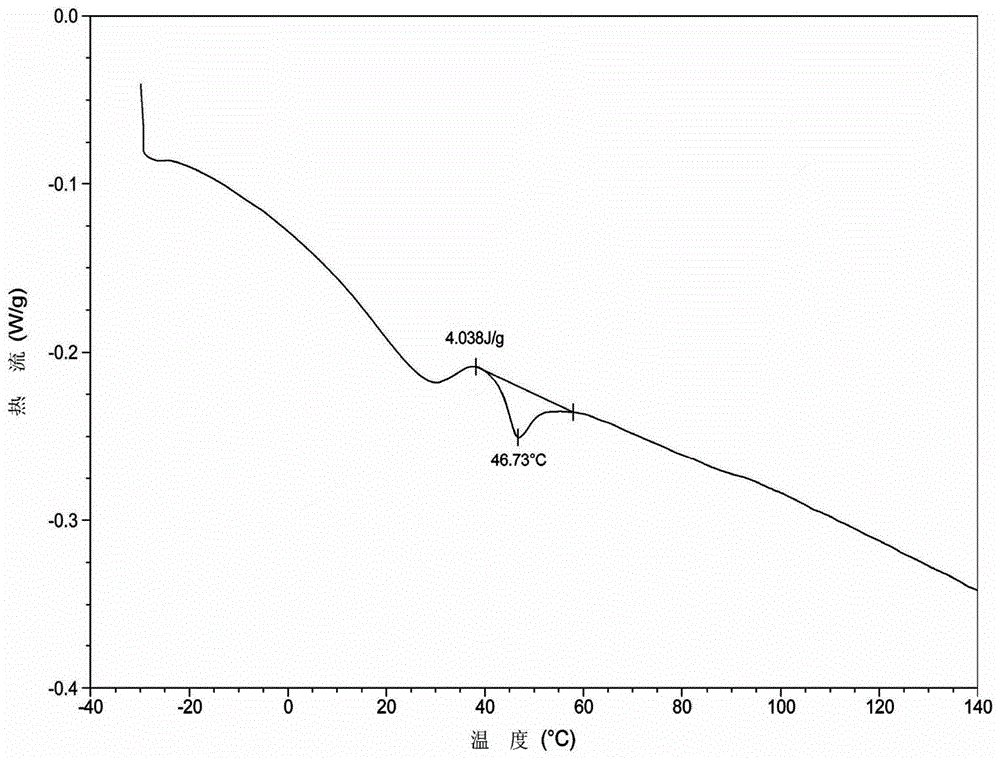

[0035] Detect according to the step and condition in embodiment 1, the temperature rising curve that draws is shown in image 3 , it can be seen from the figure that a melting endothermic peak appears at 46.73°C. After integrating the peak, the enthalpy value is 4.038J / g, which is greater than the criterion of 0.1J / g. The test result is that the sample Contains semi-crystalline gum, which is consistent with the addition of semi-crystalline gum in the prepared sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| enthalpy | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com