Multi-subcell compound photovoltaic cell

A technology of photovoltaic cells and compounds, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as insufficient absorption of natural sunlight spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the best implementation mode, and the beneficial effects of the present invention will become clear in the detailed description.

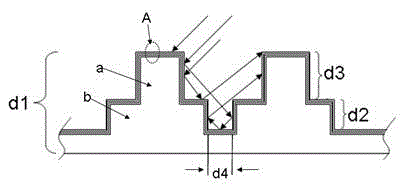

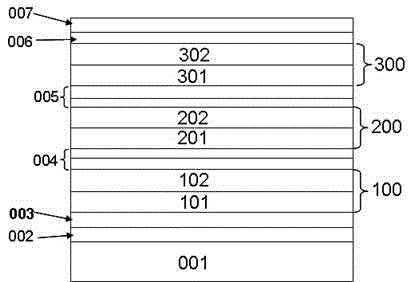

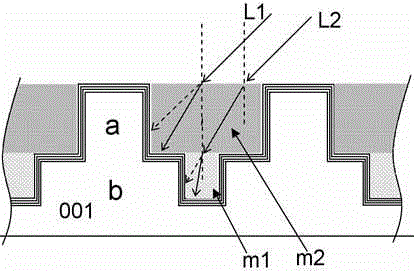

[0015] see Figure 1-3 , figure 1 It is a schematic diagram of the structure of a three-subjunction photovoltaic cell, figure 2 for figure 1 Enlarged view of area A in Middle, which shows details of the photovoltaic cell of the present invention; for an aspect of the present invention, see figure 2 The compound photovoltaic cell of the present invention has a multi-junction InAlAsP / InGaAs / Ge structure, wherein the InAlAsP subcell (300) has a band gap of about 1.9 eV, the InGaAs sub cell (200) has a band gap of about 1.40 eV, and the Ge sub cell The bandgap of (100) is about 0.66ev. The optimized structure of the bandgap of the triple-junction photovoltaic cell of the present invention can match the wavelength structure of the natural solar spectrum, make full use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com