Composite material having improved electrical conductivity and molded part containing same

A technology of composite materials and molded products, applied in the field of composite materials, can solve the problems of poor processing performance of resin, easy decomposition of carbon black, thermal stability and damage of other physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

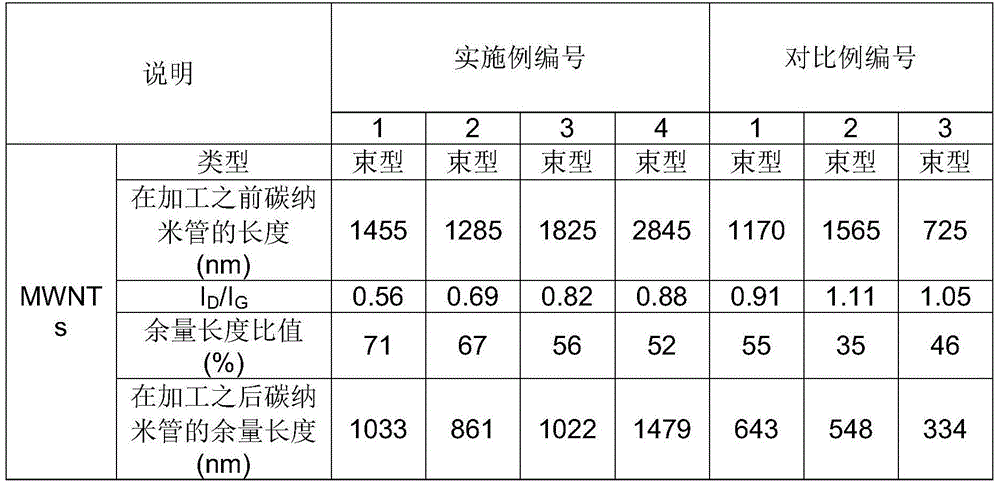

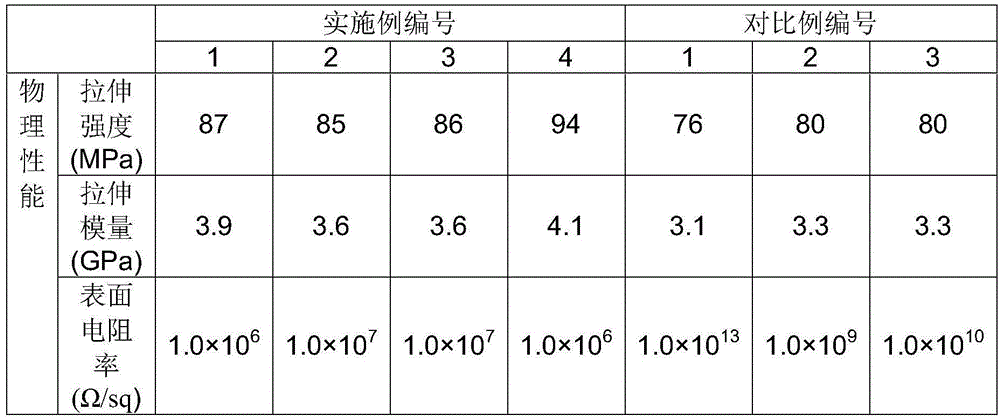

Embodiment 1-4 and comparative example 1-3

[0078] 3 wt% of carbon nanotubes, 1 wt% of carbonaceous conductive agent, and 96 wt% of polyamide resin (LUMID GP-1000B) were mixed together. The mixture was extruded at 280° C. from a twin-screw extruder (L / D=42, φ=40 mm) to prepare pellets with a size of 0.2 mm×0.3 mm×0.4 mm.

[0079] The pellets were molded in an injection molding machine at a temperature of 280° C. under flat airfoil conditions to prepare long bone-shaped samples with a thickness of 3.2 mm and a length of 12.7 mm. The samples were maintained at 23°C and 50% RH for 48 hours.

[0080] [Table 1]

[0081]

[0082]The average length of bundled carbon nanotubes used as raw material before processing was measured by dispersing powdered carbon nanotubes in solution by ultrasonication for 30 seconds to 2 minutes, and imaging the dispersion on the wafer by SEM , and the SEM images were analyzed using Scandium 5.1 (Olympus soft Imaging Solutions GmbH, Germany).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap